Beating-up device of high-speed rapier towel loom

A technology of towel looms and rapiers, which is applied in looms, textiles, textiles, and papermaking, etc. It can solve the problems that the reed and the reed seat cannot be disassembled, it is inconvenient to clean and replace, and the vibration of the machine tool is obvious, so that it is easy to clean and replacement work, simple structure, and the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

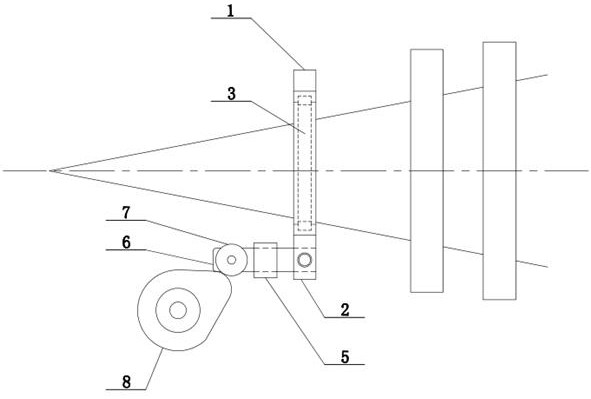

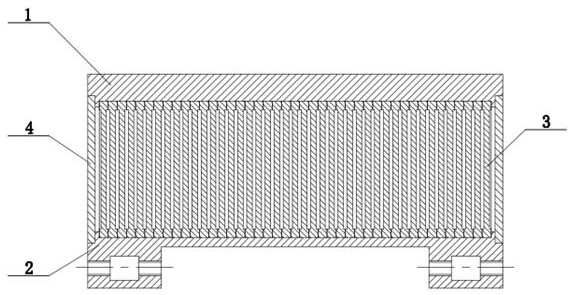

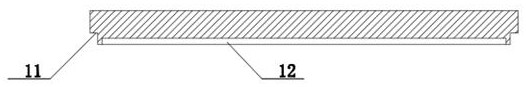

[0021] see Figure 1-Figure 5 As shown, the technical solution adopted in this specific embodiment is: it comprises reed installation upper seat 1, steel reed installation lower seat 2, reed 3, connecting plate 4, guide rail mounting seat 5, guide rail 6, roller 7, cam 8 The reed installs the upper seat 1 and the steel reed installs the lower seat 2 through the connecting plate 4 that is arranged symmetrically on both sides; and then the steel reed installs the upper seat 1, the steel reed installs the lower seat 2 and the connecting plate 4 to form a steel reed installation frame; 3 There are arrays, and they are all placed side by side in the reed installation frame; the guide rail mounting seats 5 are symmetrically arranged on both sides of the machine body, the guide rail 6 passes through the guide rail mounting seats 5, and the connection relationship between the guide rail 6 and the guide rail mounting seats 5 is sliding Connect; one end of the guide rail 6 is connected ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap