U-shaped inward-folding rotating mechanism of balance wheel sliding groove

A rotating mechanism, U-shaped technology, applied in the direction of pivot connection, instrument, identification device, etc., can solve the problems of inconvenient industrialized manufacturing and large number of spare parts, and achieve the effect of simple and effective structural design and easy industrialization implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this example, if Figure 15 As shown, A is the stroke change of the flexible screen during the bending process, and B is the relationship between the angle change of the mechanism rotation process and the position change of the screen, that is, the sliding constant length refers to the flexible screen during the whole bending process. The relative position of the rotating mechanism 8 does not change, and the position adjustment during the bending process is satisfied by the change of the trajectory of the rotating mechanism 8, so that the constant length of the flexible screen does not change during the bending process.

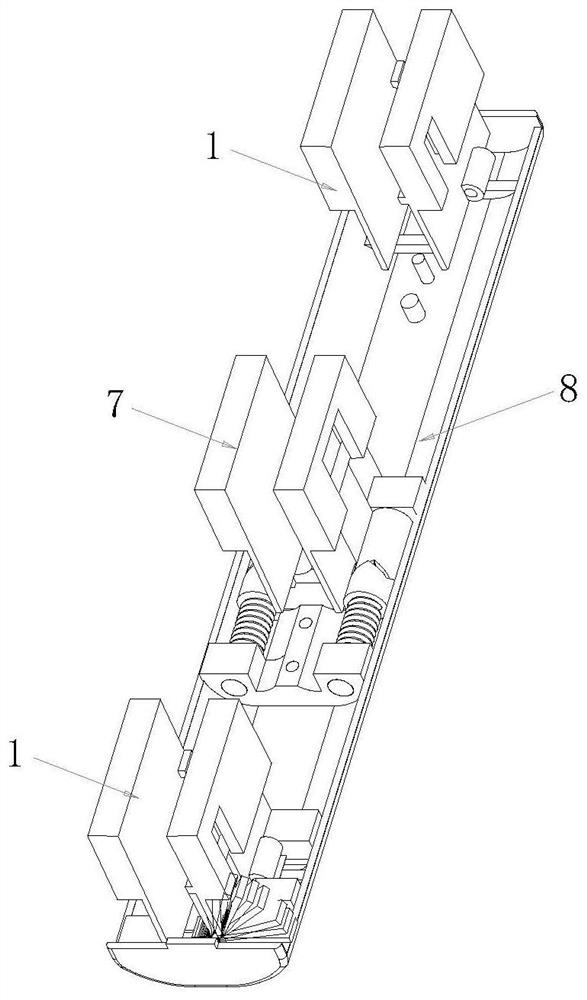

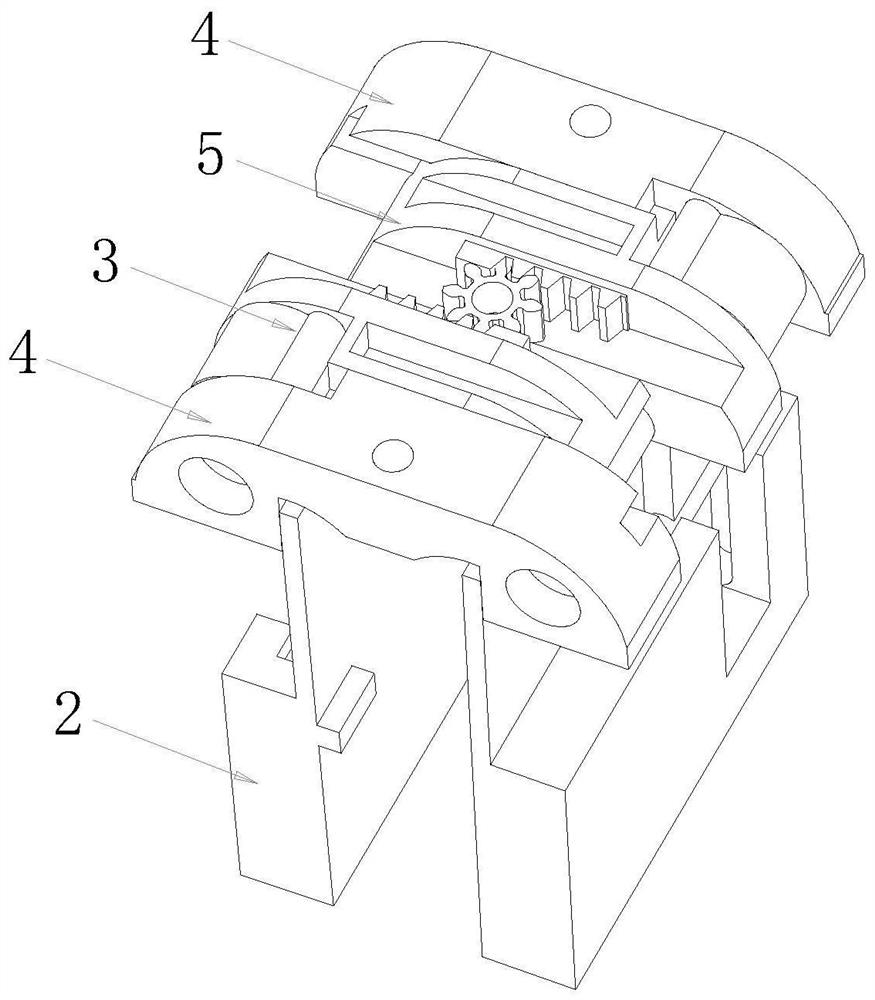

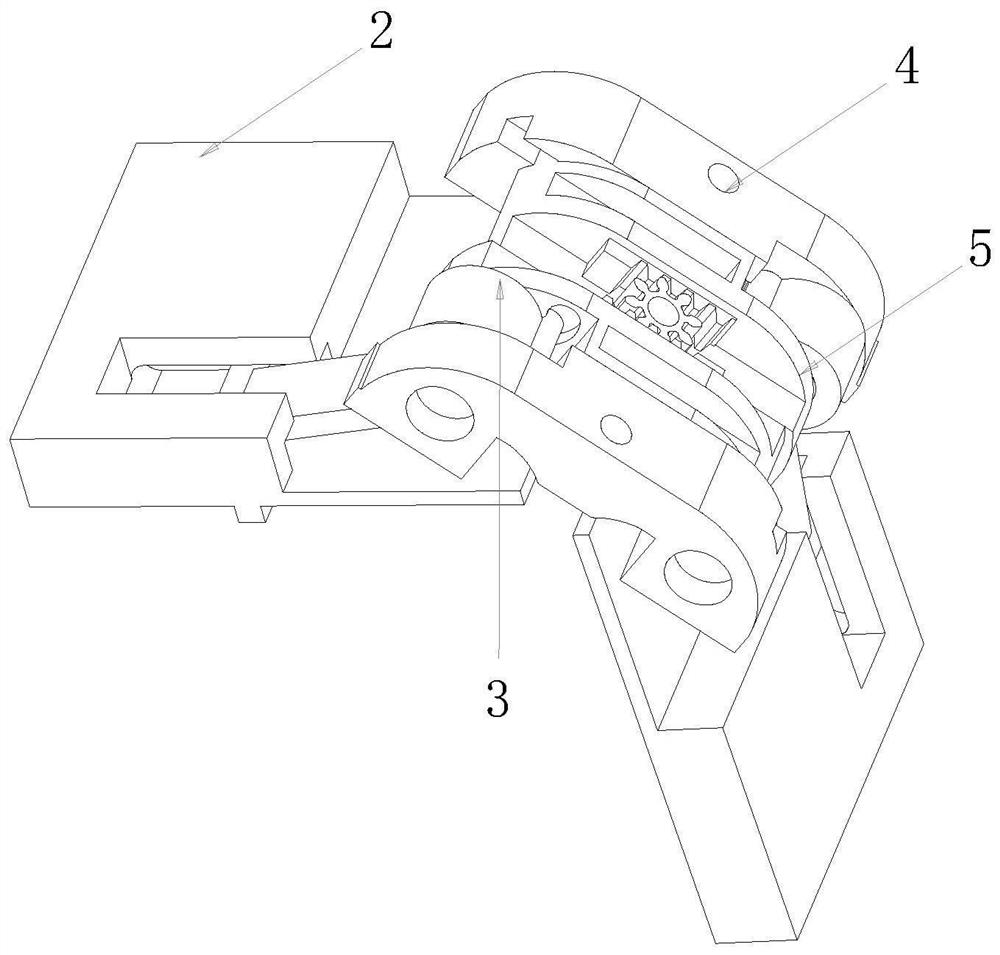

[0033] Such as Figure 1-16 As shown, the U-shaped inward turning mechanism for curved groove bending disclosed in this embodiment includes a main body of the mechanism, and the main body of the mechanism includes two sets of side rotating shafts 1, and the side rotating shafts 1 are composed of laterally symmetrically distributed Two groups of tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com