Constant-dew-point-temperature and variable-flow heat pump dehumidification type precision air conditioner and control method thereof

A dew point temperature, heat pump dehumidification technology, applied in heating methods, air conditioning systems, heating and ventilation control systems, etc., can solve the problems of low heating efficiency, difficult temperature and humidity control accuracy, high power consumption, etc., to improve the control accuracy. , optimization method and control logic strategy, the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

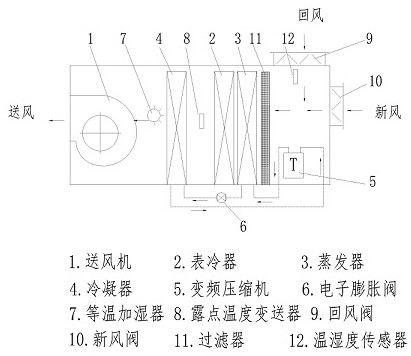

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] see figure 1 , the constant dew point temperature variable flow heat pump dehumidification type precision air conditioner and its control method are composed of a blower (1), a surface cooler (2), a variable flow heat pump system, an isothermal humidifier (7), and a dew point temperature transmitter (8) , fresh air valve (9), return air valve (10), filter (11) and temperature and humidity sensor (12); the variable flow heat pump system includes frequency conversion compressor (5), electronic expansion valve (6), evaporator ( 3) and the condenser (4), the working principle is that the high temperature and high pressure exhaust of the inverter compressor (5) first passes through the condensation of the condenser (4) and then becomes a high pressure and low temperature condensed liquid, which is precisely condensed by the electronic expansion valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com