Boresighting system and boresighting method for hoisting type head-up display

A head-up display and target calibration technology, which is applied in the direction of instruments, measuring instruments, measuring devices, etc., can solve the problems of cumbersome and complicated implementation process, difficult operation, and many manpower and material resources, so as to reduce environmental requirements, reduce target calibration process, and The effect of target process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

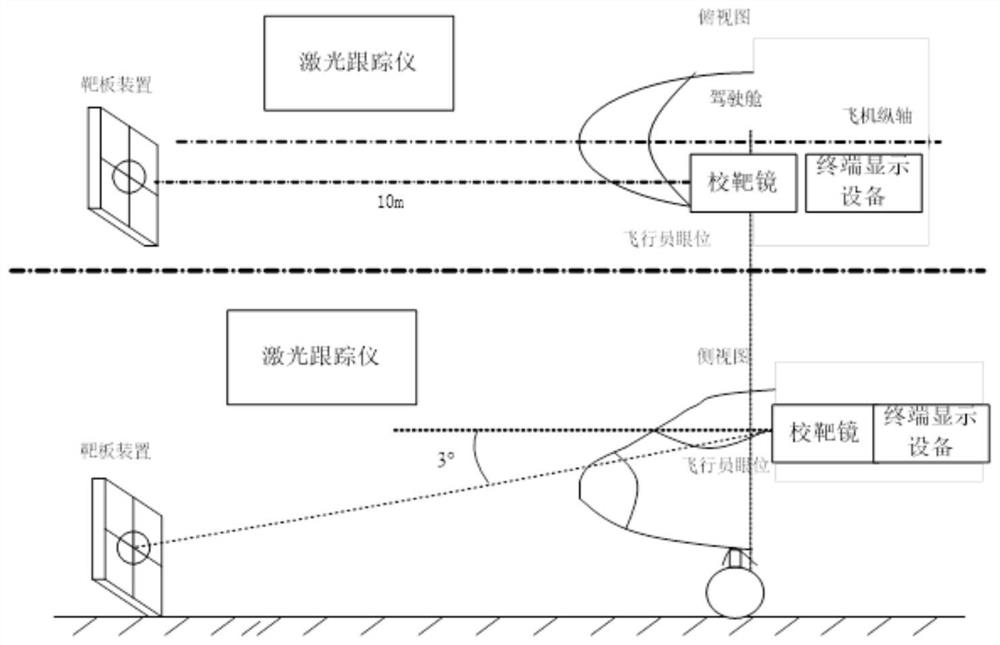

[0033] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

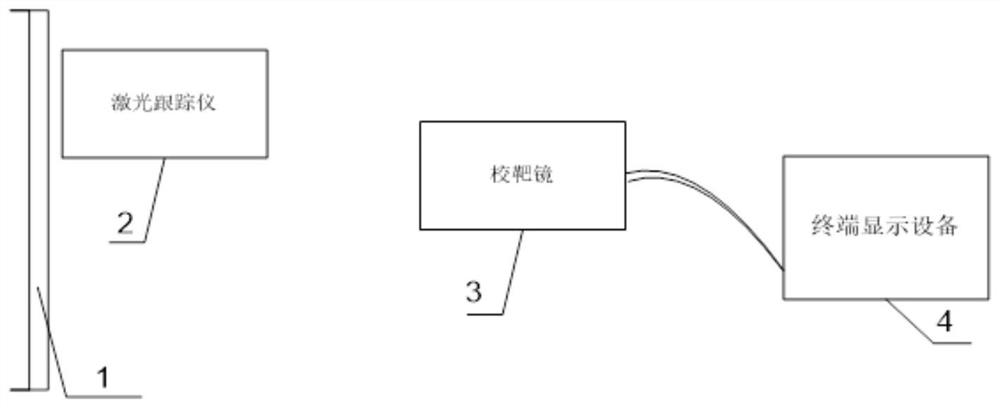

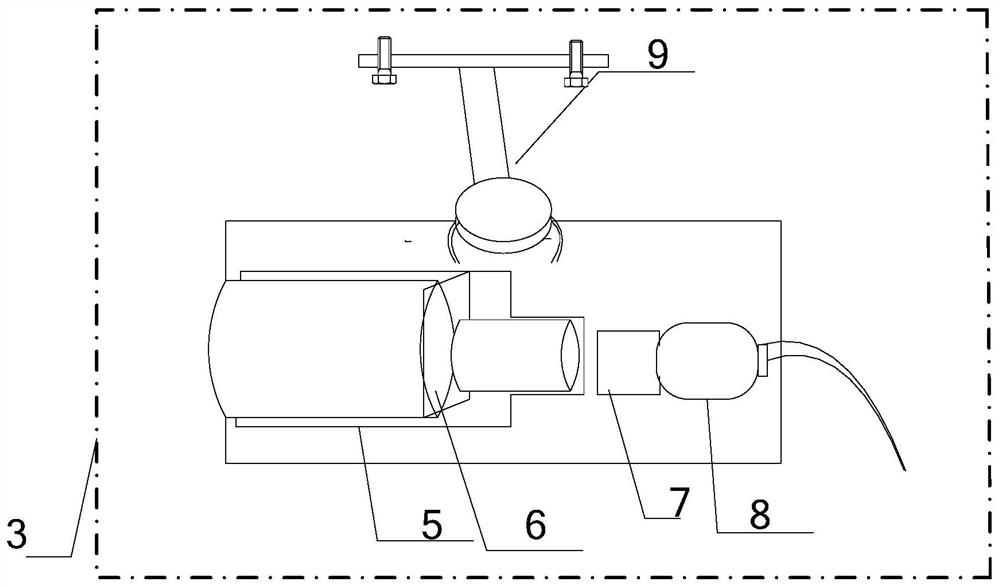

[0034] The target calibration equipment includes a target plate device, a laser tracker, a target calibration mirror and a terminal display device (including a video capture card), wherein the target plate device is composed of a base, an adjustment mechanism and a target surface, and the target calibration mirror consists The board is composed of a monocular, a telephoto lens, a camera and a transfer mechanism, and the terminal display device is composed of a video capture card and a display screen.

[0035] The target plate device has a target surface with a cross line and a circular pattern. The target surface is installed on the base of the target plate through an adjustment mechanism; the adjustment mechanism can realize the movement of the target surface up and down, left and right, and front and rear directions. The base can adjust the target surface by ±1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com