High-voltage electroscope clamping hook

An electroscope and clip hook technology, applied in the field of electric power, can solve the problems such as insufficient contact between the electroscope hook and the electroscope conductive head, and achieve the effects of accurate and reliable electroscope results and increased contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

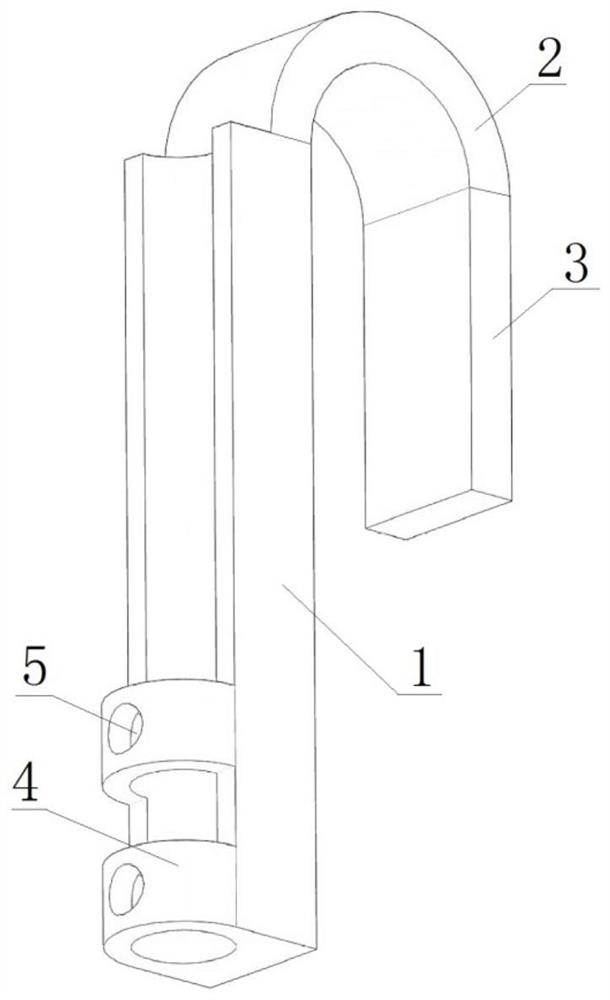

[0029] This embodiment provides a kind of high voltage electroscope clip hook, such as figure 1 As shown, the clip hook includes: a first hook arm 1, a second hook arm 3, and an arc connector 2;

[0030] The upper end of the first hook arm 1 is connected to one end of the arc-shaped connector 2, and the other end of the arc-shaped connector 2 is connected to the second hook arm 3, so that the clip hook is U-shaped;

[0031] The front of the first hook arm 1 is opposite to the front of the second hook arm 3, and the back of the first hook arm 1 is provided with a guide groove along the vertical direction;

[0032] The lower end of the first hook arm 1 is provided with a connecting ring 4, and the connecting ring 4 communicates with the guide groove.

[0033] The guide groove is a semicircular guide groove. The guide groove is arranged coaxially with the connecting ring 4, and the radius of the connecting ring 4 is equal to the radius of the guide groove.

[0034] The number ...

Embodiment 2

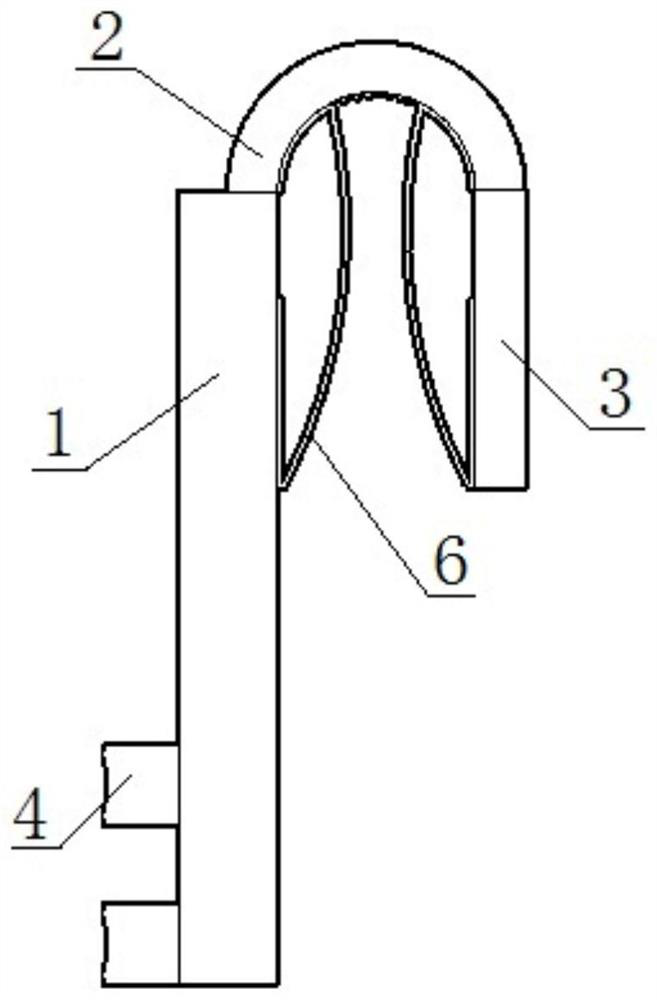

[0038] This embodiment provides a kind of high voltage electroscope clip hook, such as figure 2 As shown, the clip hook includes: a first hook arm 1, a second hook arm 3, and an arc connector 2;

[0039] The upper end of the first hook arm 1 is connected to one end of the arc-shaped connector 2, and the other end of the arc-shaped connector 2 is connected to the second hook arm 3, so that the clip hook is U-shaped;

[0040] The front of the first hook arm 1 is opposite to the front of the second hook arm 3, and the back of the first hook arm 1 is provided with a guide groove along the vertical direction;

[0041] The lower end of the first hook arm 1 is provided with a connecting ring, and the connecting ring 4 communicates with the guide groove.

[0042] The guide groove is a semicircular guide groove.

[0043] The guide groove is arranged coaxially with the connecting ring 4, and the radius of the connecting ring 4 is equal to the radius of the guide groove.

[0044] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com