Cooling transformer

A technology of transformers and refrigerators, applied in the field of transformers, can solve problems such as accelerating the aging of internal structure lines, affecting service life, and unsatisfactory heat dissipation effects of transformers, etc., to achieve the effect of ensuring cooling and cooling effects, ensuring cooling effects, and sufficient three-dimensional distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

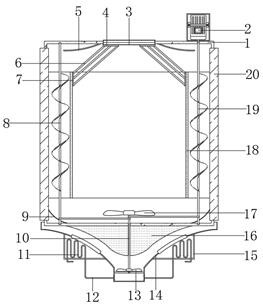

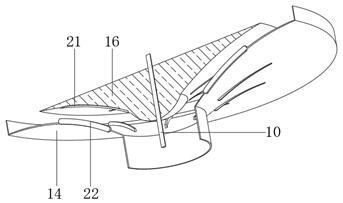

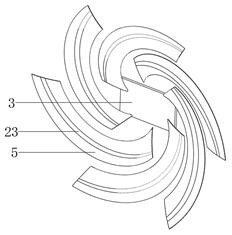

[0029] refer to Figure 1-4 , a cooling transformer, including a transformer main body 1, the bottom outer wall of the transformer main body 1 is fixedly installed with an air inlet arc end 14, and the end of the air inlet arc end 14 is equidistantly opened with an air outlet facing the edge of the transformer main body 1, The bottom outer wall of the transformer body 1 is fixed with a gas distribution block 16 by bolts, and the bottom outer wall of the gas distribution block 16 is provided with air guide grooves 21 distributed equidistantly, and the gas distribution block 16 is connected to the opposite side of the transformer body 1 through bearing rotation There is a rotating rod 10, and the two ends of the rotating rod 10 are respectively fixedly equipped with a blower vane 13 and a blower vane 2 17, and the outer wall of the bottom end of the air intake arc end 14 is fixed with a bottom water tank 15 by bolts, and the bottom water tank 15 Equidistantly distributed heat ex...

Embodiment 2

[0039] refer to Figure 5 , a cooling transformer. Compared with Embodiment 1, this embodiment also includes that the top end of the heat exchange connecting plate 6 is welded with heat exchange rings 24 whose specifications increase from top to bottom.

[0040] In the present invention, the top outer walls of the heat exchange ring fins 24 are fixedly installed with vertical fins 25 distributed equidistantly.

[0041] When the present invention is used: the heat exchange rings 24 arranged on the heat exchange connecting plate 6 are utilized, and because the specifications thereof increase sequentially from top to bottom, the three-dimensional distribution of the heat exchange rings 24 in space is relatively sufficient, and the vertical space of the vertical plates 25 is matched. The setting can further improve the heat exchange area and air conduction effect of the heat exchange ring plate 24, so as to achieve the purpose of ensuring the cooling effect of the transformer main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com