High-voltage cable deicing equipment for electric power detection

A power detection and high-voltage technology, applied in cable installation, electrical components, overhead installation, etc., can solve problems such as increase, cable damage, cable burden, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

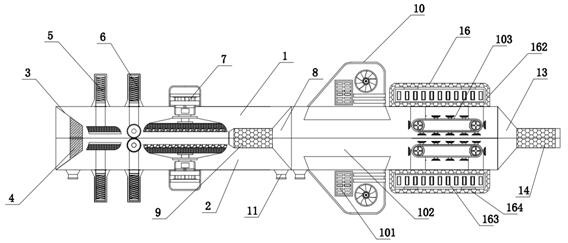

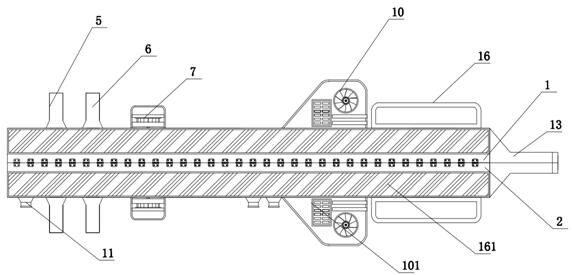

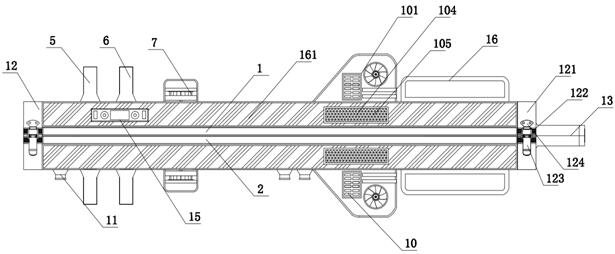

[0038] see Figure 1-8 , a high-voltage cable deicing device for power detection, comprising an upper casing 1 and a lower casing 2, the upper casing 1 and the lower casing 2 are hinged to each other through a hinge, the upper casing 1 and the lower casing The casings 2 are all made of plastic material, and the left end of the upper casing 1 and the lower casing 2 are fixedly connected with a half arc bucket 3, and the base body of the half arc bucket 3 is made of plastic material. The inner side of the half arc bucket 3 is fixedly connected with the heating arc plate 4, and the right side of the left end half arc bucket 3 in the upper casing 1 and the lower casing 2 is fixedly connected with the first deicing assembly 5. The inside of the upper housing 1 and the lower housing 2 on the right side of the first deicing assembly 5 are all fixedly installed with an ice-breaking assembly 6, and the inside of the upper housing 1 and the lower housing 2 on the right side of the ice-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com