Garlic and peanut harvester

A harvester and peanut technology, applied in the field of agricultural machinery, can solve the problems of low utilization rate of the harvester, large damage to the harvested material, high labor intensity, etc., and achieve the effects of high yield, increase product yield, and reduce labor effort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

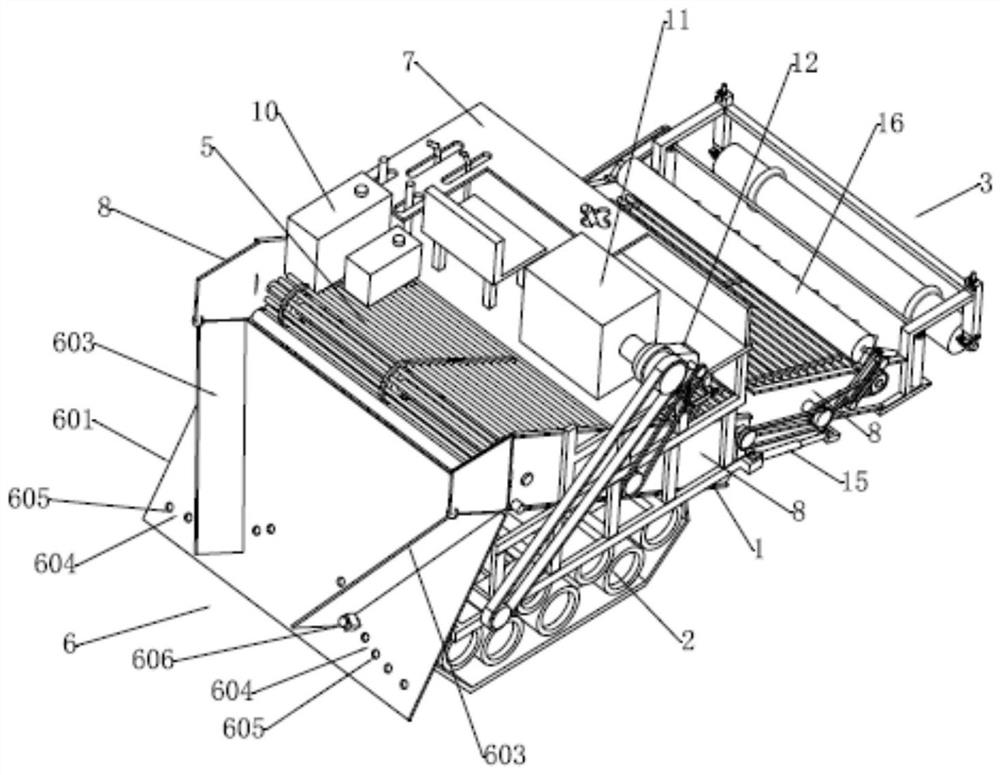

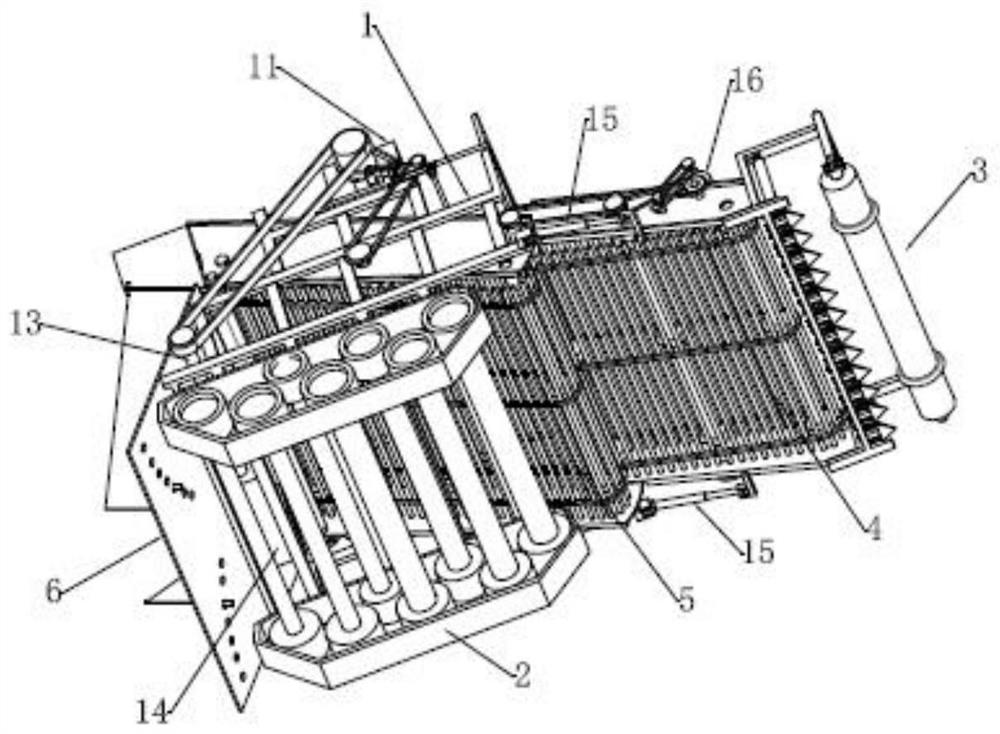

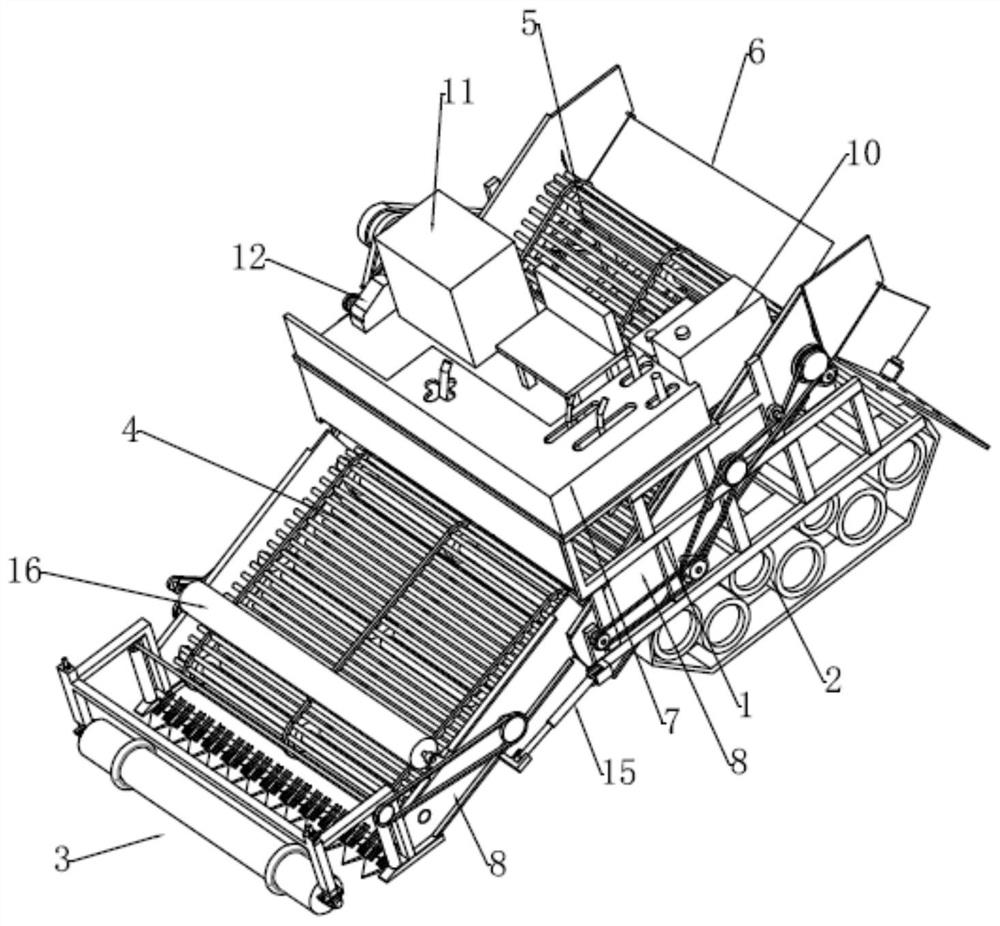

[0034] A harvester for garlic and peanuts, comprising a vehicle frame 1, a crawler walking device 2, an excavating device 3, a primary conveying device 4, a secondary conveying device 5, a diversion device 6, a control platform 7 and a soil pressing device;

[0035] The crawler belt running device 2 is arranged at the bottom of the frame 1, the secondary conveying device 5 is fixed upwardly in the frame 1 through the mounting plates 8 on both sides, and the primary conveying device 4 is fixed through the mounting plates 8 on both sides. Tilt upward and be hinged at the bottom of the front end of the vehicle frame 1. The blanking end of the primary conveying device 4 is arranged above the feeding end of the secondary conveying device 5. The excavating device 3 is installed on the front end of the primary conveying device 4. The deflector 6 is installed at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com