A self-adaptive polishing device for special-shaped iron crafts

A polishing device and a technology for special-shaped surfaces, which are applied in grinding/polishing safety devices, surface polishing machine tools, grinding drive devices, etc. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

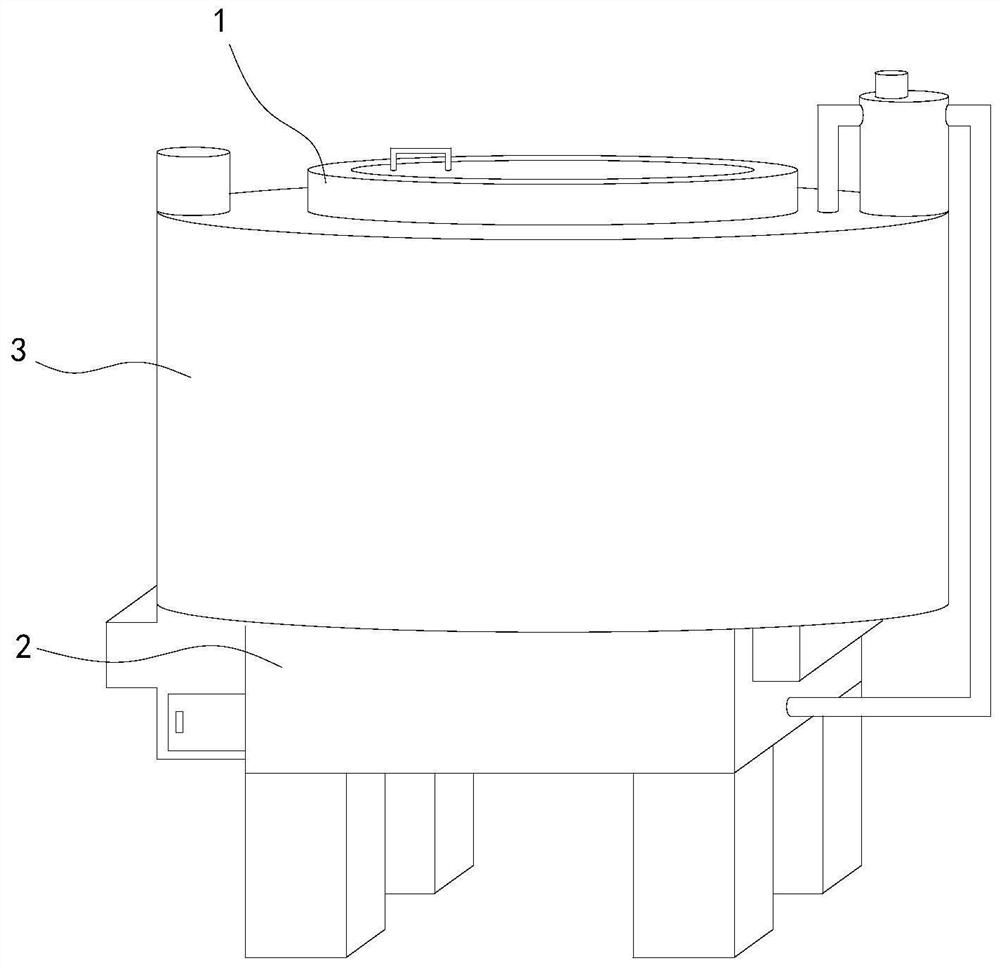

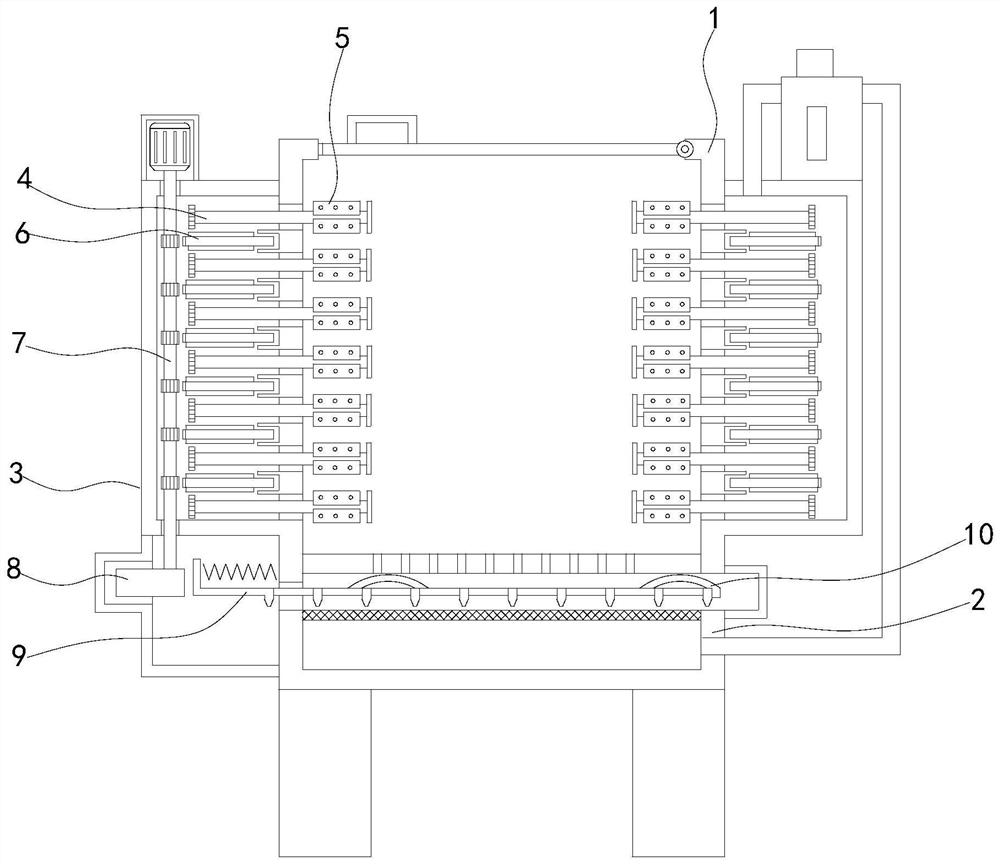

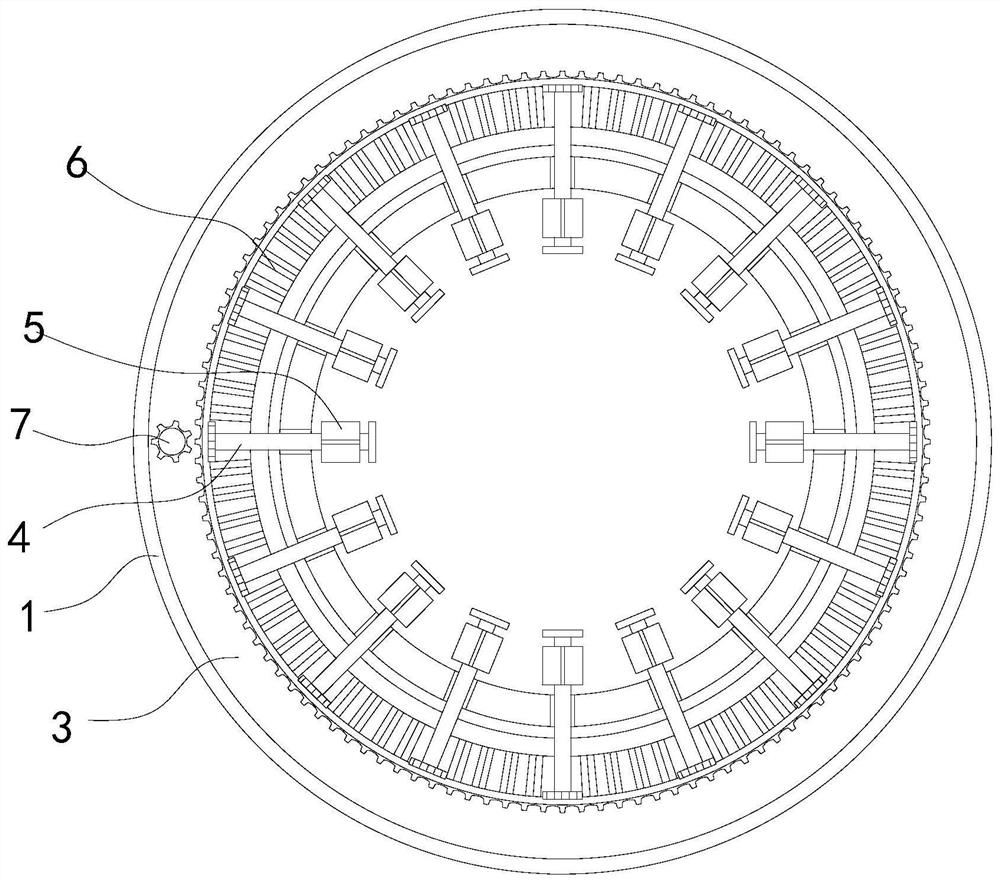

[0027] see Figures 1 to 9 , a plane structure schematic diagram and a three-dimensional structure schematic diagram of an adaptive polishing device for special-shaped iron crafts.

[0028] A self-adaptive polishing device for special-shaped surfaces of wrought iron products, comprising a device main body 1, a recovery device 2 is fixedly installed at the lower end of the device main body 1, a water adding chamber 3 is fixedly installed outside the device main body 1, and a bonding device 4 is movably installed inside the water adding chamber 3, A pressing plate 5 is movably installed on the outside of the laminating device 4 .

[0029] In a specific implementation, one end of the fitting device 4 passes through the water filling chamber 3 and enters the interior of the device main body 1, and a plurality of same setting fitting devices 4 are equidistantly installed inside the water adding chamber 3, so that when water is added to the inside of the water adding chamber 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com