Lifting manipulator of injection machine

A technology for lifting and lowering manipulators and injection machines, applied in manipulators, manufacturing tools, etc., can solve the problems of not being able to upgrade and transform old products, the precision of manipulators is not high, and cannot be generalized, so as to save space and improve production quality. , the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

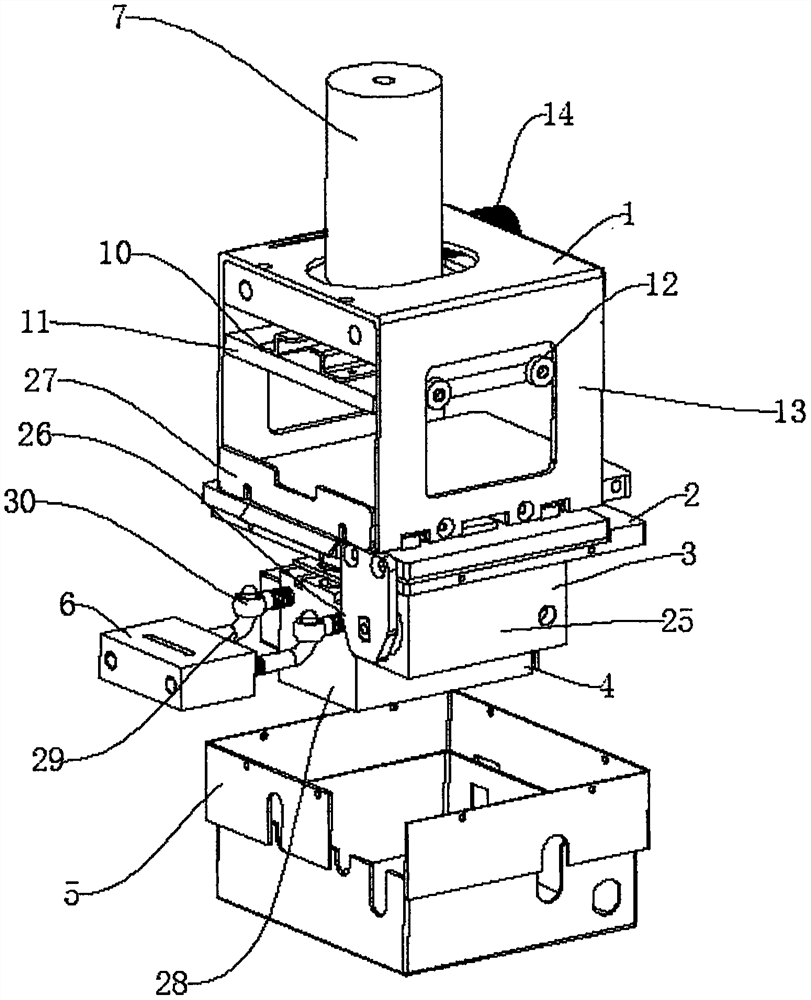

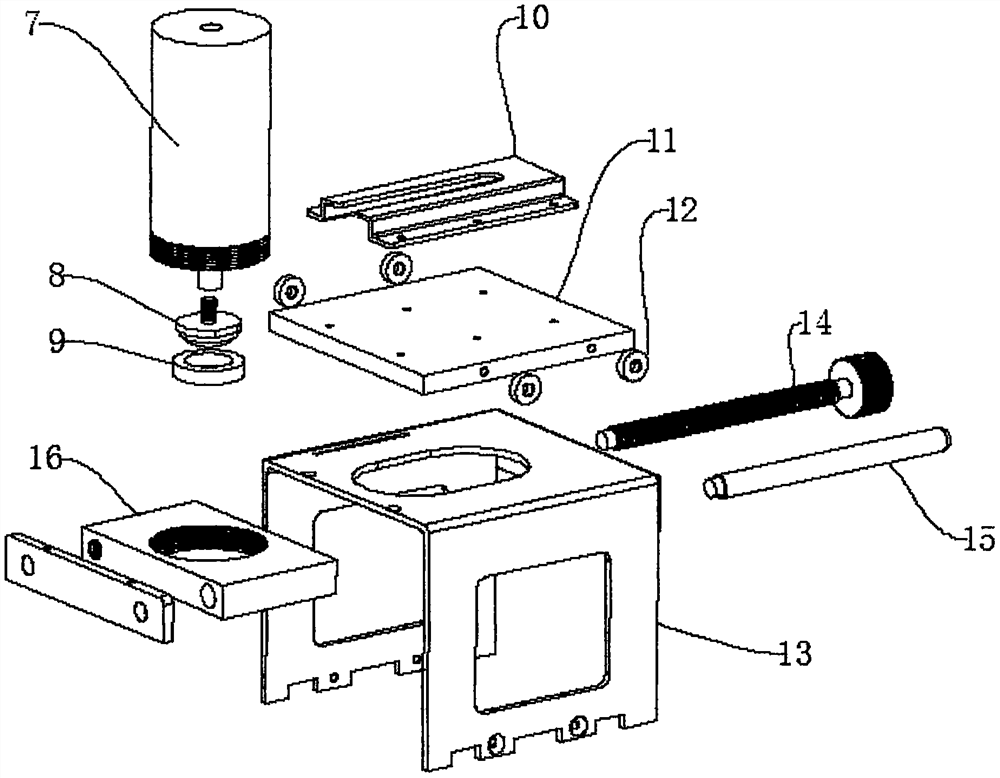

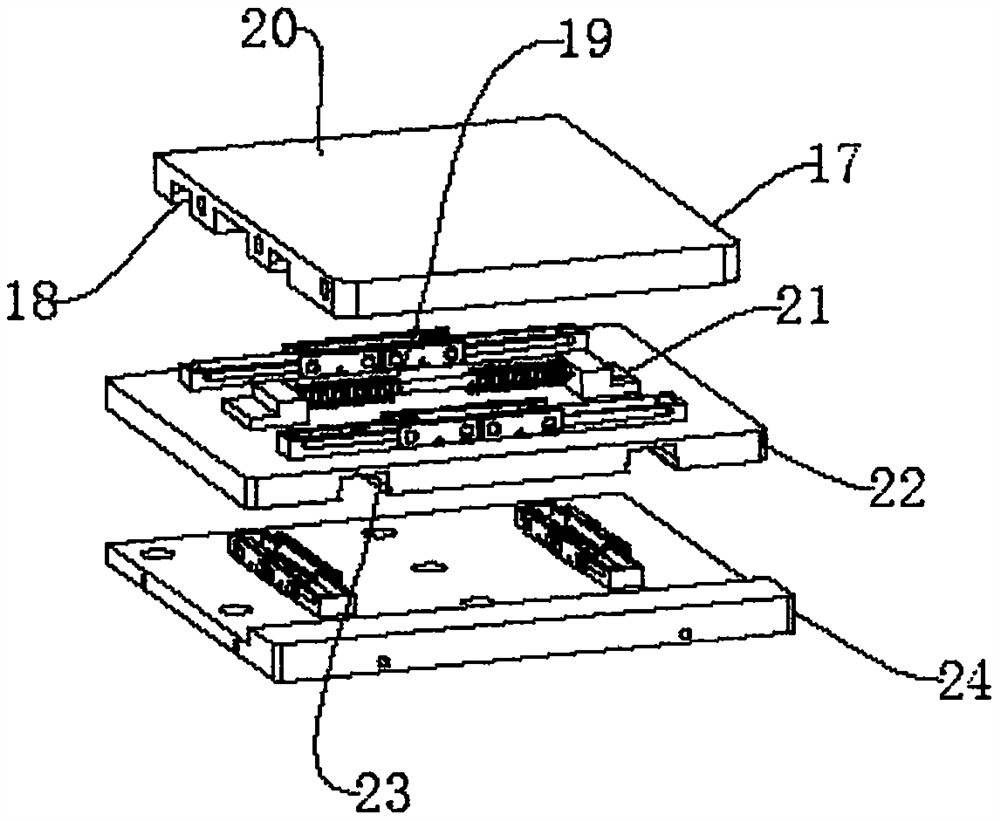

[0038] Such as Figure 1-Figure 4 As shown, the injection machine lifting manipulator includes a pressing structure 1 and a base modification shell 5. A supporting frame 13 is arranged on the pressing structure 1, a pressing cylinder 7 is arranged on the top of the supporting frame 13, and a movable curved surface is arranged at the bottom of the pressing cylinder 7. Part 8, a bowl-shaped part 9 is arranged at the bottom of the movable surface part 8, a lower pressing plate 11 is arranged in the support frame 13, a lower pressing plate adjustment guide rail 10 is arranged on the top of the lower pressing plate 11, and a lower pressing slide rail bearing 12 is arranged on both sides of the lower pressing plate 11 , the bottom of the bowl 9 is provided with a cylinder mobile platform 16, a lead screw 14 is provided on the outer side wall of the support frame 13, a slide rail ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap