Electrolysis device and clothes treatment equipment

A technology for clothing treatment equipment and electrolysis device, which is applied to washing devices, other washing machines, textiles and paper making, etc., can solve problems such as water leakage, loosening of screws, poor sealing performance of electrolysis devices, etc. The effect of elastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be noted that, in the case of no conflict, the embodiments in the application and the technical features in the embodiments can be combined with each other. Undue Limitation of This Application.

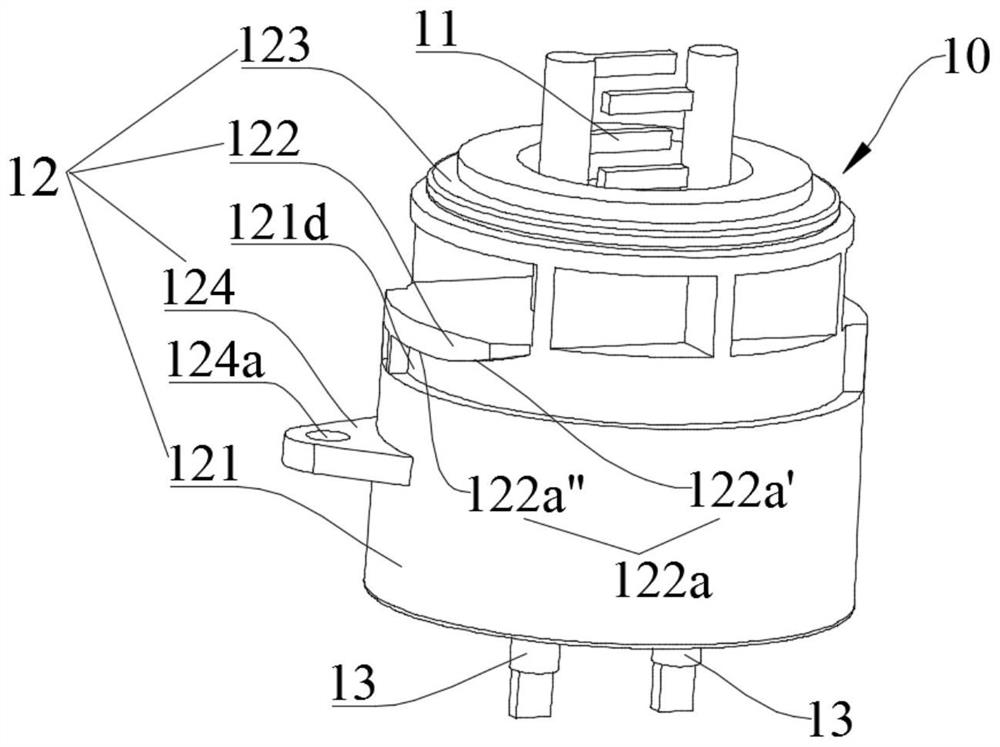

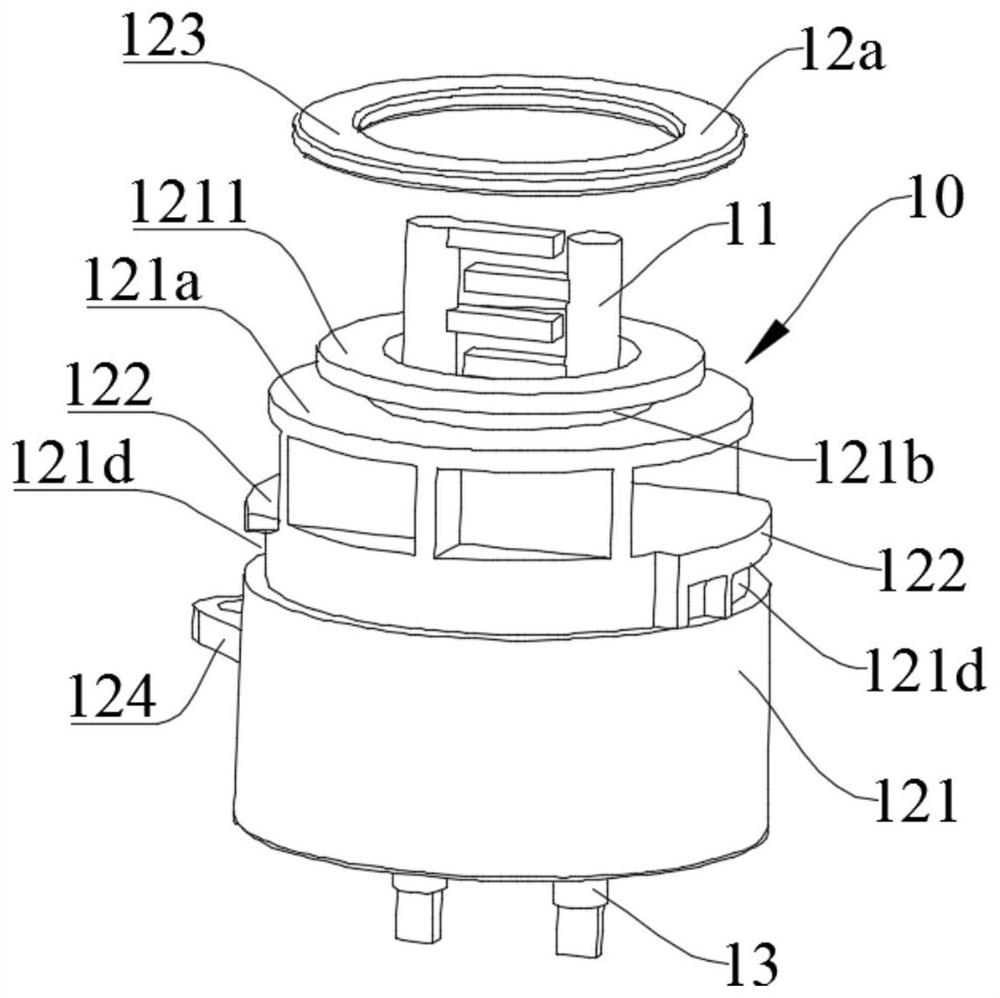

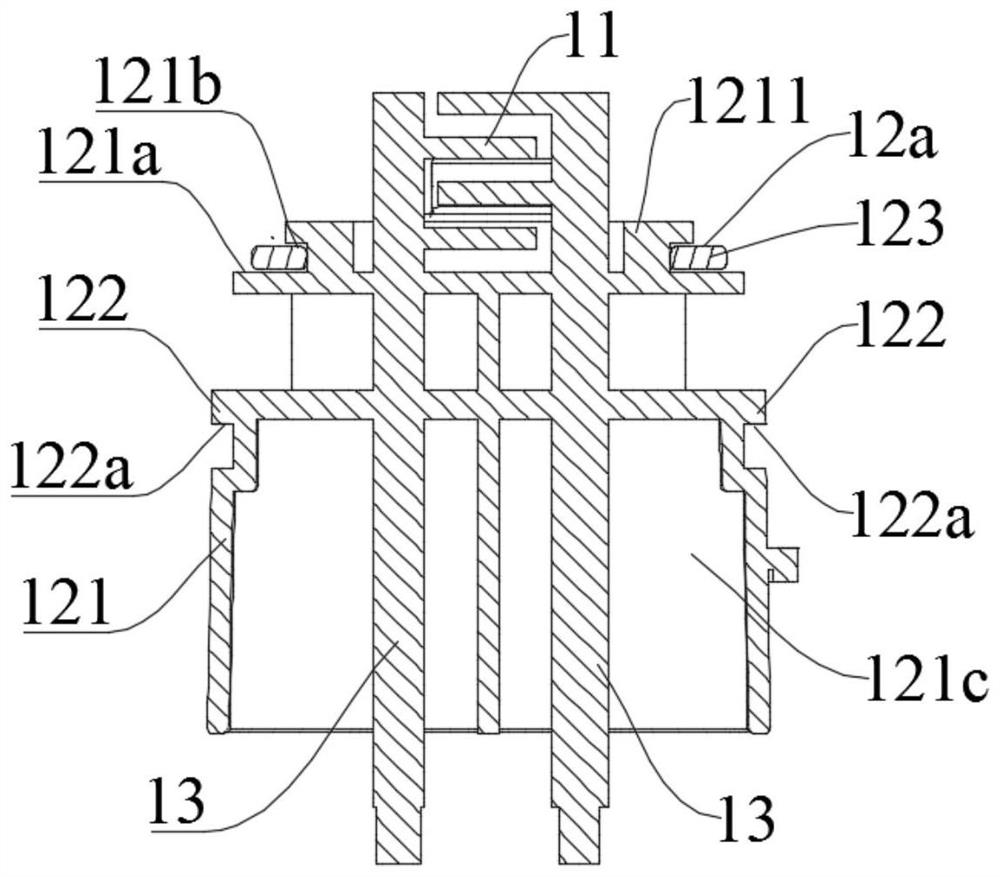

[0037] The embodiment of the present application provides an electrolysis device 10, please refer to figure 1 with figure 2 , including an electrode 11 and a mounting device 12, wherein the mounting device 12 includes a screwing body 121 and a locking portion 122 arranged on the surface of the screwing body 121, the electrode 11 is located on the first side of the screwing body 121, and the locking portion 122 is away from One side of the electrode 11 is formed with a locking surface 122a, and the locking surface 122a extends along the circumferential direction of the screw body 121, and the mounting device 12 is formed with a sealing structure 12a facing the first side.

[0038] Taking the application of the electrolysis device 10 in clothes treatment equipment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com