Intelligent textile processing equipment with good dustproof effect

A technology of intelligent processing and textiles, applied in the field of textile intelligent processing equipment, can solve the problems of poor adjustment ability of dust removal area, physical injury of staff, and influence on the quality of textile processing, etc., to improve the quality and efficiency of dust removal, and have strong adaptability and adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

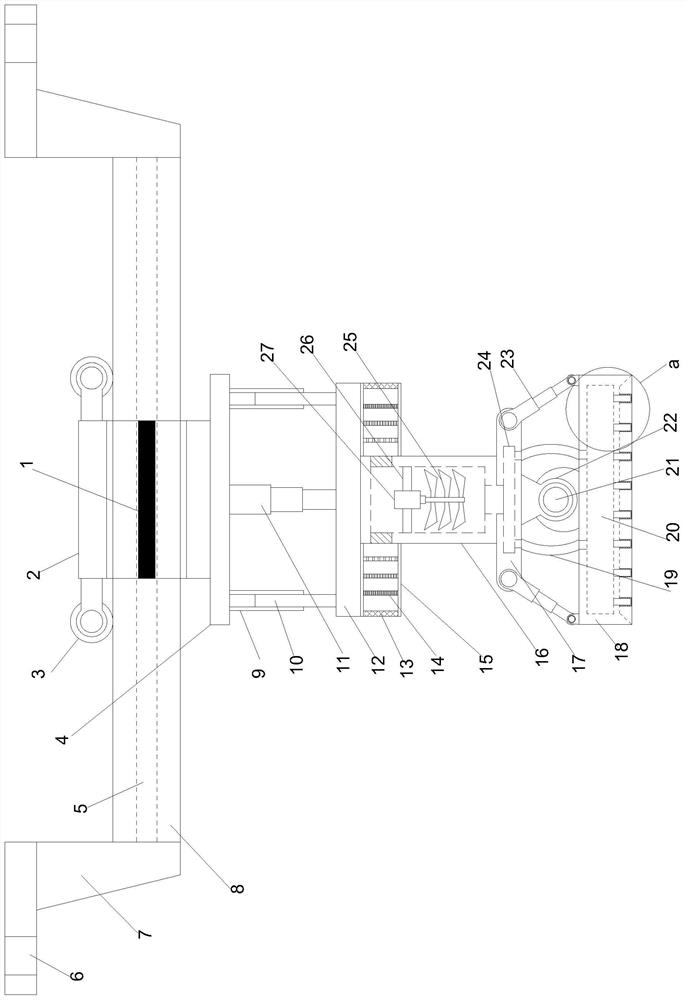

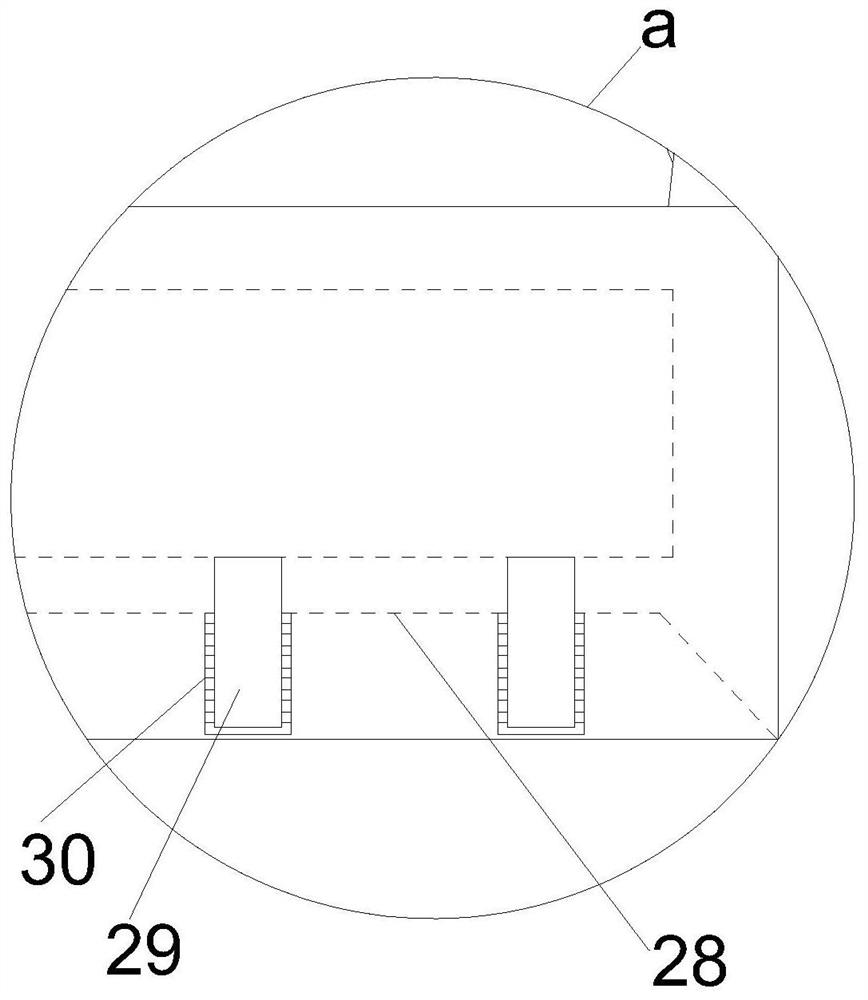

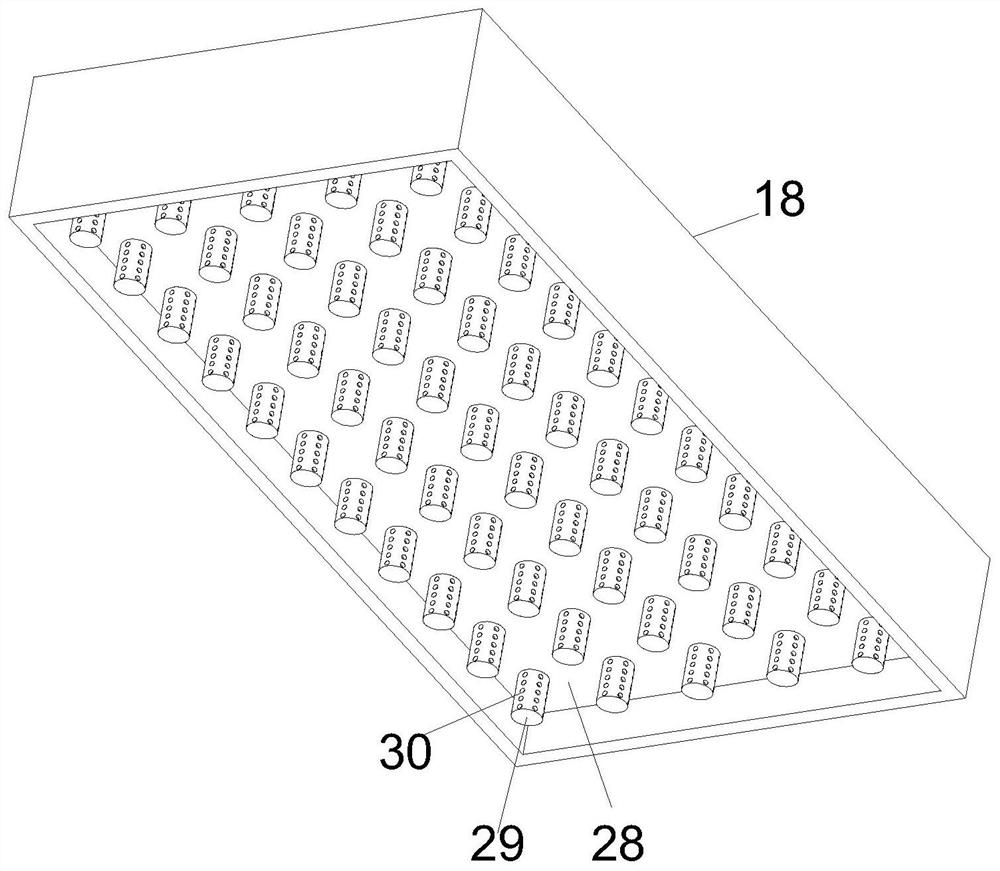

[0022] see Figure 1~3 , in the embodiment of the present invention, a kind of textile intelligent processing equipment with good dust-proof effect, comprises the support installation column 8 that is arranged horizontally, and the two ends of support installation column 8 are symmetrically provided with fixed installation frame 7, and fixed installation frame 7 is provided with There are fixed installation holes 6, and the outer side of the support installation column 8 is horizontally provided with a mobile installation cylinder 2, and the two ends of the upper side of the mobile installation cylinder 2 are symmetrically provided with a mobile guide wheel 3 through the installation frame, and the lower side of the mobile guide wheel 3 is installed with the support The columns 8 are in contact with each other, the front and rear sides of the support installation column 8 are horizontally provided with guide installation grooves 5, the inner side of the mobile installation cyli...

Embodiment 2

[0025] On the basis of Embodiment 1, through the expansion and contraction of the swing telescopic column 23, and with the cooperation of the support shaft 21 and the support installation frame, the angle adjustment of the swing guide cover 18 is completed to adapt to the angle of different processing equipment, so that the swing guide The cover 18 fits the working area as closely as possible to improve the dust removal effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com