Multifunctional motor mounting rack

A mounting frame and multi-functional technology, which can be applied in the direction of machine/support, supporting machine, mechanical equipment, etc., can solve the problems of consuming workers' physical strength, easy to cause potential safety hazards, and increase workers' labor intensity, so as to improve the shock absorption effect and alleviate the Workers' labor intensity and the effect of less stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

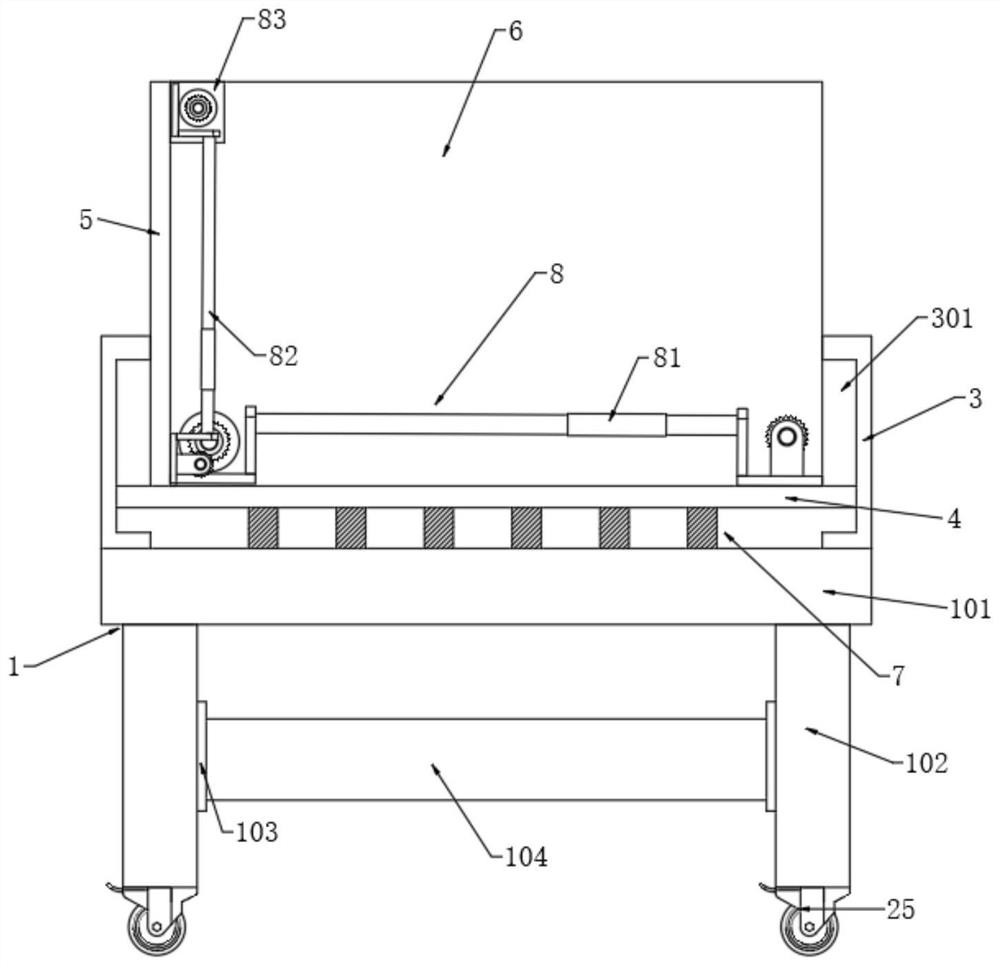

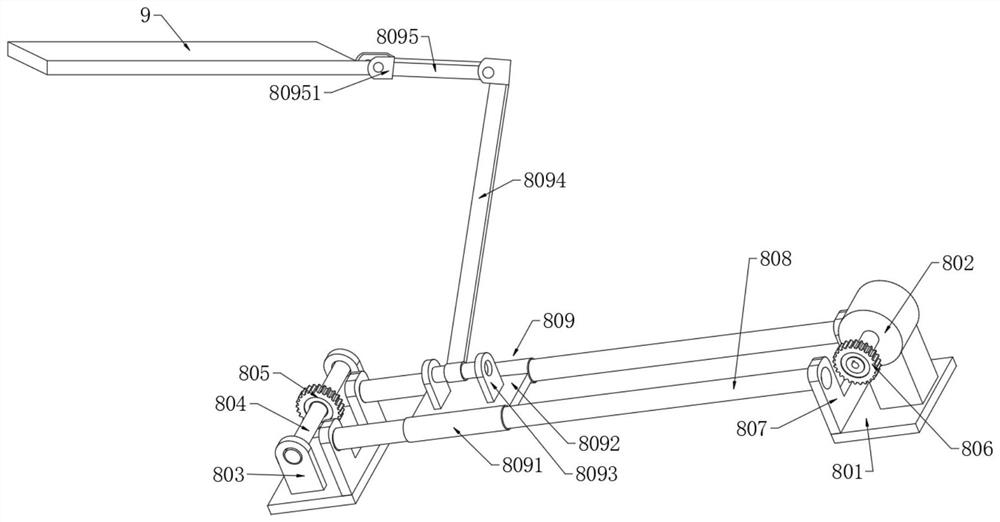

[0040] Please refer to the attached Figure 1-6 , a mounting frame for a multifunctional motor, comprising:

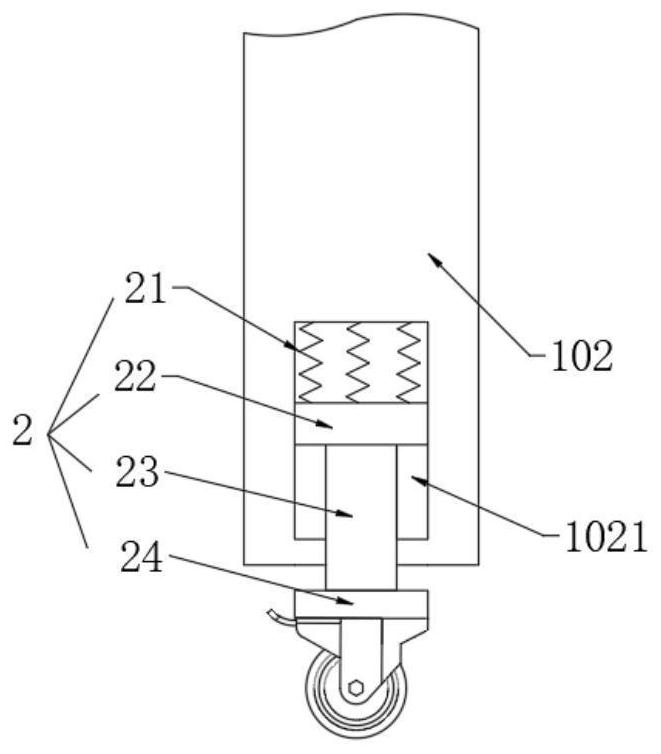

[0041] Support base 1, support base 1 comprises support plate 101, and the four corners of the support plate 101 lower surface are fixed with support legs 102 by screws, and the section of support leg 102 close to the ground is a cavity structure, and there are slides in the cavity. Groove 1021, the first damping device 2 is slidably connected to the chute 1021;

[0042] Further, in order to improve the shock absorption effect of the device when it moves, a section of the support leg 102 close to the ground is a cavity structure, and a chute 1021 is opened in the cavity, and the chute 1021 is slidably connected with the first shock absorption device 2 ;

[0043] A pair of skateboards 3, a pair of skateboards 3 are formed on the left and right sides of the support plate 101, and grooves 301 are formed on the adjacent surfaces of the pair of skateboards 3;

[0044]Fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com