Ball pin assembly torsion test marking device and test method

A technology of torque testing and ball pins, which is applied in the field of ball pin assembly torque testing and marking devices, can solve the problems of poor detection accuracy, immature ball pin torque detection technology, low torque detection efficiency, etc., and achieve detection efficiency improvement, fast Easy to read results, easy to read results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

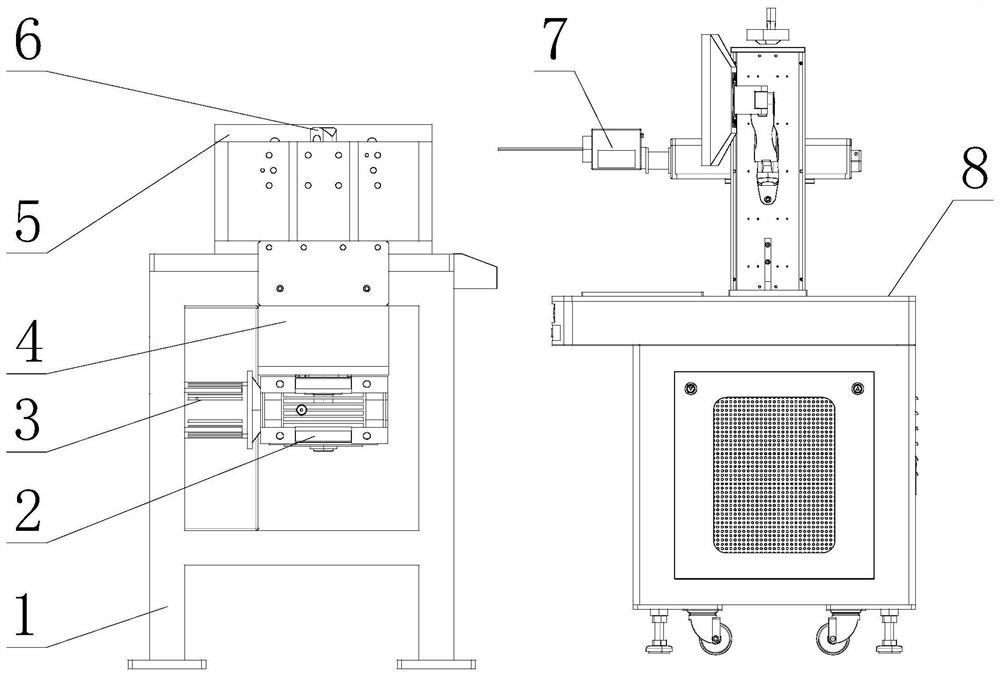

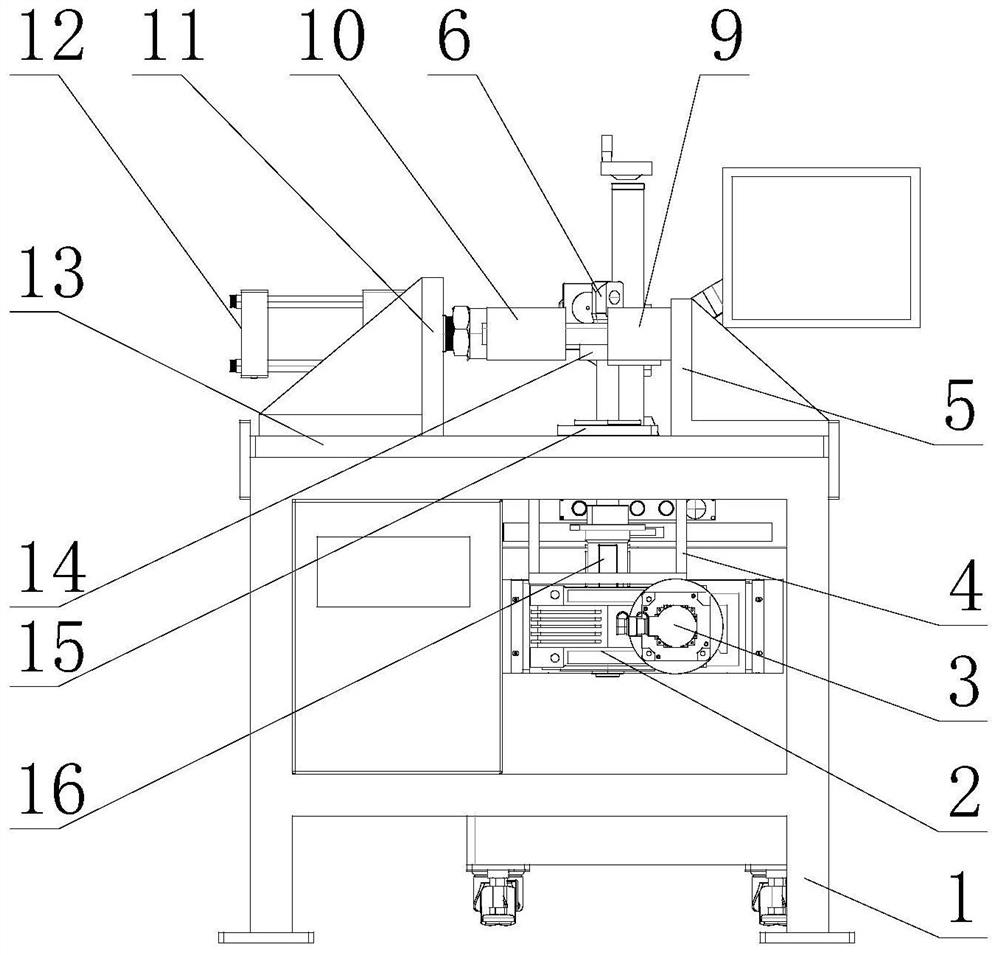

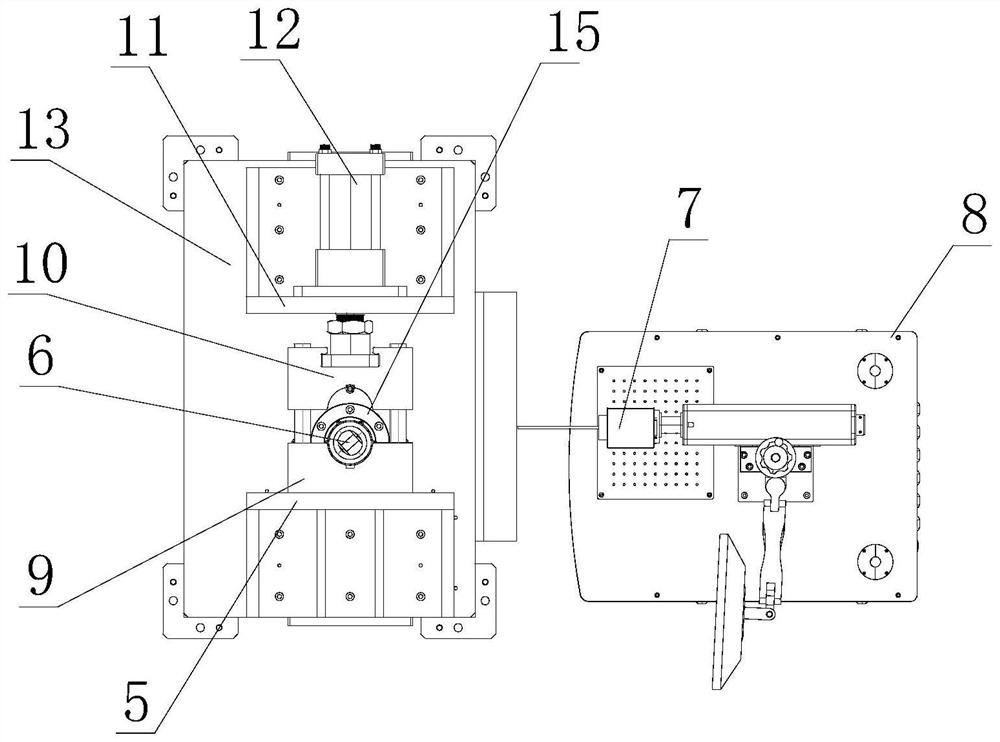

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0024] A ball pin assembly torque testing marking device, the ball pin assembly includes a ball pin 6 and a joint bearing outer casing 14 that is rotatably installed outside the ball pin 6, when the ball pin assembly is installed on the equipment and is in a normal working state, due to excessive There is a pre-tightening force in the installation, and it needs to reach a certain torque value before it can rotate. The target of the test here is the torque value of the rotation of the joint bearing casing 14. The device includes a platform 13, which is installed above the platform 13 and acts on the joint bearing casing 14. The limit pre-tightening mechanism and the power part acting on the ball pin 6 are installed un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com