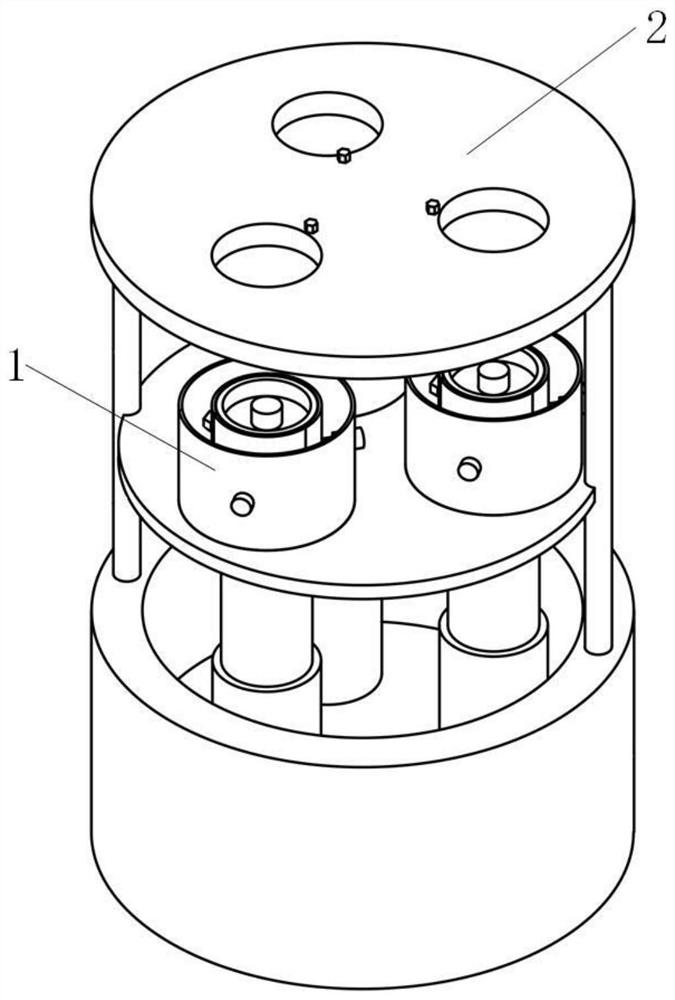

Recycled water-stabilized macadam unconfined compressive strength sample forming mold

A technology for compressive strength and forming molds, which is applied in the field of unconfined compressive strength sample forming molds for recycled water-stabilized crushed stone, which can solve the problems of large physical strength consumption of operators, damage to samples, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

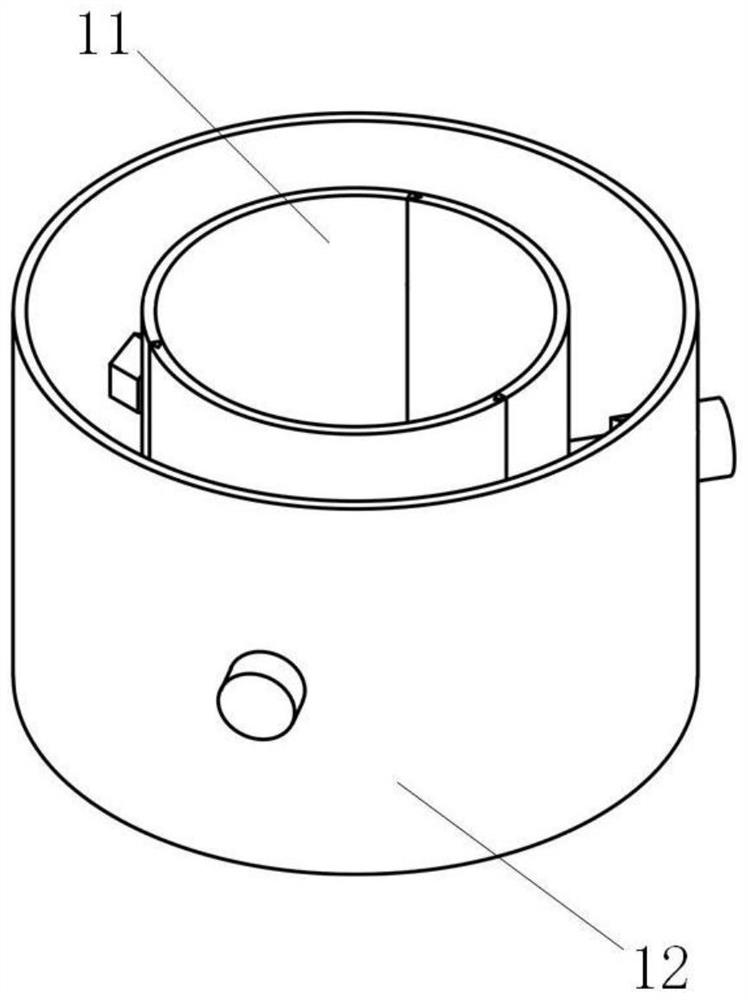

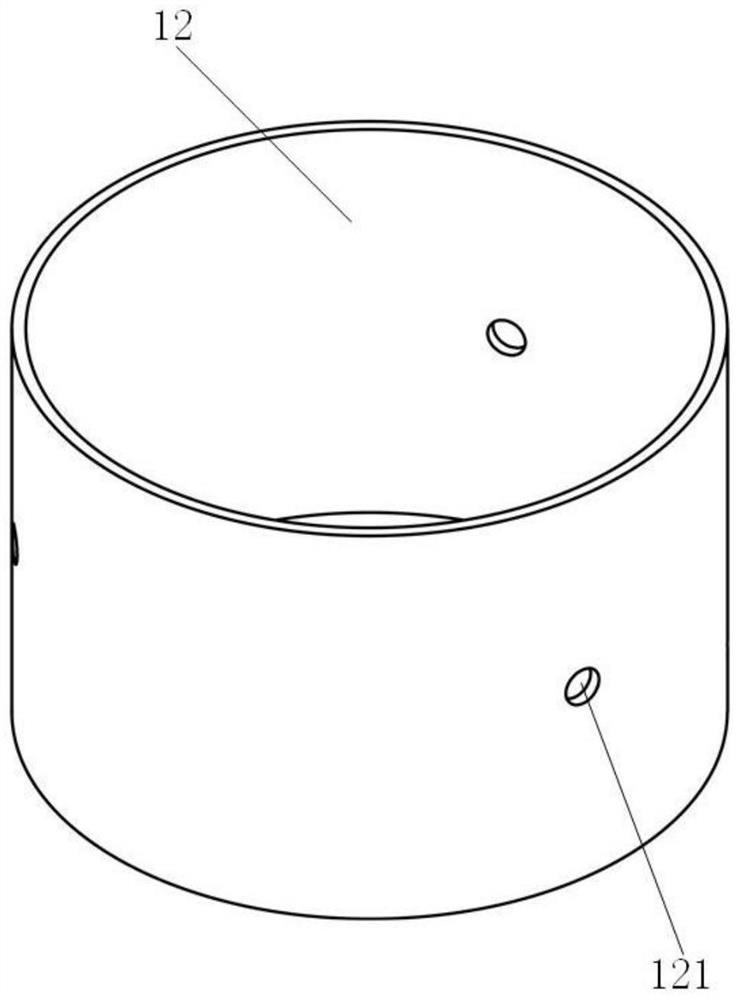

Embodiment 1

[0036] In the prior art, before the measurement of the unconfined compressive strength test sample, it needs to be compacted and demoulded, and the compaction and demoulding operations are completed by different equipment, and the compaction and demoulding are mostly performed by manual hydraulic pressure. The jack consumes a lot of physical strength during operation, and only one sample can be operated at a time, so the work efficiency is low; at the same time, due to the heavy weight of the sample and the mold cylinder, its stability is poor, and deviations are likely to occur during the rising process. Therefore, re-alignment is required; in addition, after the traditional gravel sample is compacted, it is difficult to successfully demould due to the lateral pressure of the mold during demoulding, which is easy to cause damage to the sample.

[0037] In order to solve the problems existing in the prior art that the forming molds for unconfined compressive strength samples of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap