Coal mine accident prevention and control operation environment detection equipment and detection method

A technology for working environment and testing equipment, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of inaccurate gas concentration detection, achieve the effect of safe production environment and reduce the content of harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

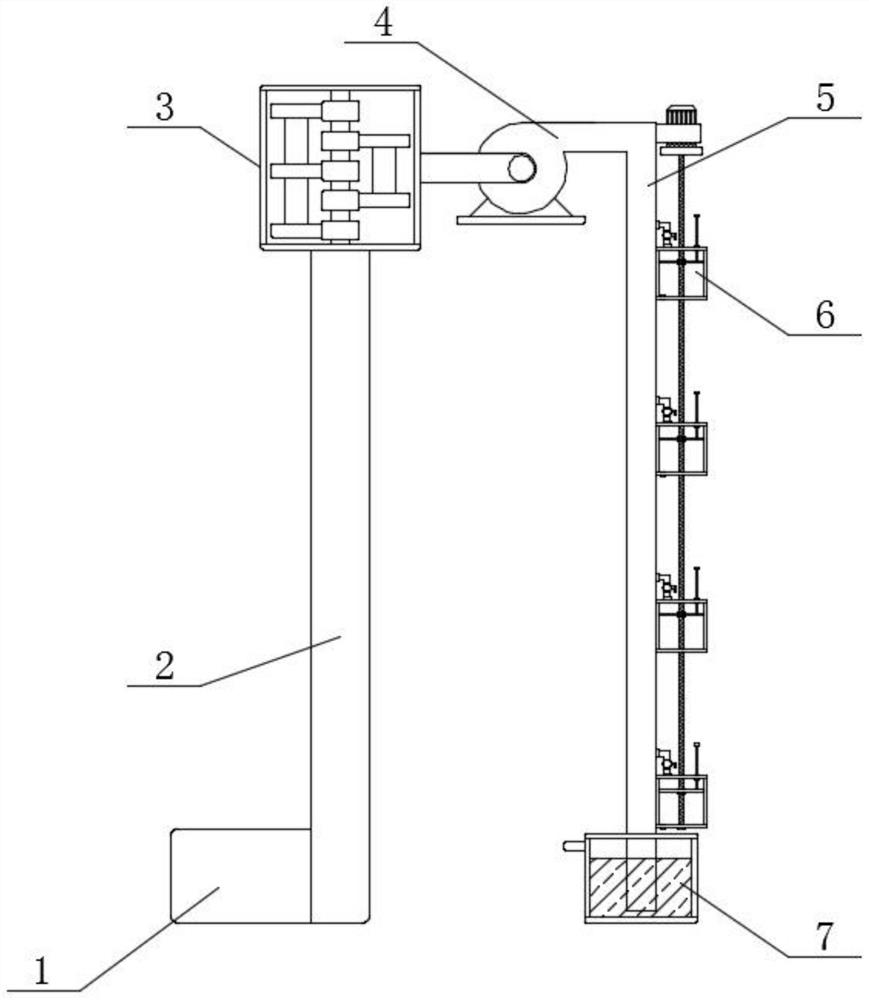

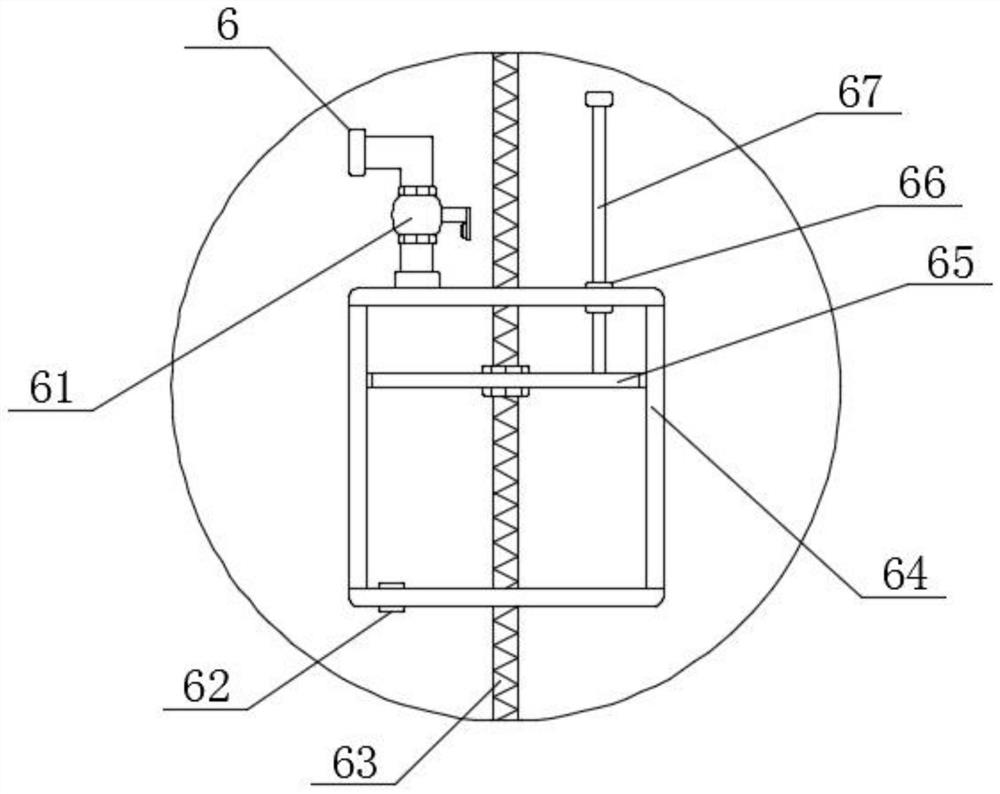

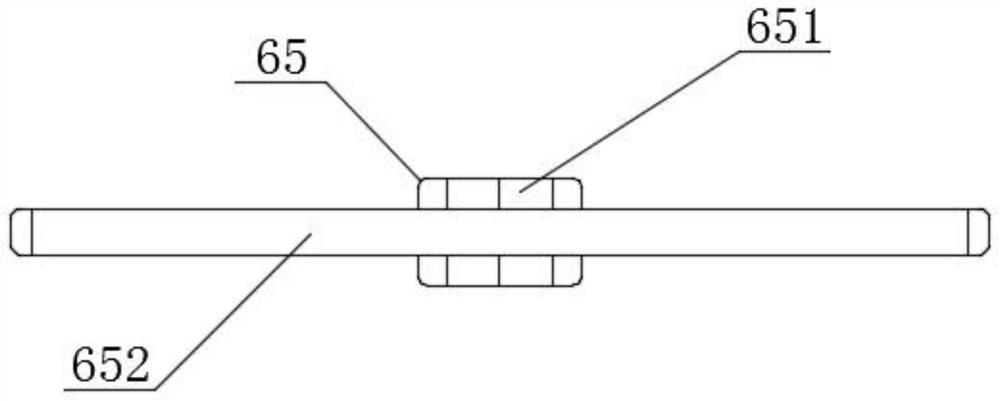

[0028] Such as Figure 1-3 As shown, the operating environment detection equipment for coal mine accident prevention and control includes a detection device 1, a connecting pipe 2 is fixed on the right end of the detection device 1, a mixing device 3 is fixed on the upper end of the connecting pipe 2, and an exhaust fan 4 is fixed on the right end of the mixing device 3 , the right end of exhaust fan 4 is fixed with air inlet pipe 5, and the right end of air inlet pipe 5 is fixed with quantitative air intake device 6, and the lower end of air inlet pipe 5 is fixed with cleaning device 7, and quantitative air intake device 6 comprises electromagnetic valve 61, electromagnetic The lower end of the valve 61 is fixed with a box body 64, the inner surface of the box body 64 is slidably connected with an extrusion plate 65, and the upper end of the extrusion plate 65 is connected with a screw 63 through thread rotation, and the right side of the screw rod 63 is at the upper end of th...

Embodiment 2

[0031] Such as Figure 1-5 As shown, the operating environment detection equipment for coal mine accident prevention and control includes a detection device 1, a connecting pipe 2 is fixed on the right end of the detection device 1, a mixing device 3 is fixed on the upper end of the connecting pipe 2, and an exhaust fan 4 is fixed on the right end of the mixing device 3 , the right end of exhaust fan 4 is fixed with air inlet pipe 5, and the right end of air inlet pipe 5 is fixed with quantitative intake device 6, and the lower end of air inlet pipe 5 is fixed with cleaning device 7, and mixing device 3 comprises mixing box 32, mixing box 32 The inner surface of the inner surface is rotatably connected with a rotating rod 31, and the outer surface of the rotating rod 31 is fixed with a stirring impeller 33.

[0032] The exhaust fan 4 draws the gas inside the air inlet pipe 5 into the mixing box 32, and the high-speed gas enters the mixing box 32 to drive the stirring impeller ...

Embodiment 3

[0034] Such as Figure 1-6 As shown, the operating environment detection equipment for coal mine accident prevention and control includes a detection device 1, a connecting pipe 2 is fixed on the right end of the detection device 1, a mixing device 3 is fixed on the upper end of the connecting pipe 2, and an exhaust fan 4 is fixed on the right end of the mixing device 3 , the right end of exhaust fan 4 is fixed with air inlet pipe 5, and the right end of air inlet pipe 5 is fixed with quantitative air intake device 6, and the lower end of air inlet pipe 5 is fixed with cleaning device 7, and cleaning device 7 comprises cleaning box 72, cleaning box 72 The left end is fixed with water inlet pipe 71.

[0035]Because the air in the coal mine production contains a large amount of coal powder and dust, after the dust enters the box body 64 through the intake pipe 66, it will follow the pipe and adhere to the inner pipe wall of each pipe, and connect the power supply of the solenoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com