Contact wrapping type arc striking structure and contact mechanism

A wrapping, contact technology, applied in the direction of contacts, contact shells/screens, electrical components, etc., can solve the problems of contact burnout, occupying space, and long arc retention time, avoiding movement and improving live use. Life, the effect of reducing arc damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

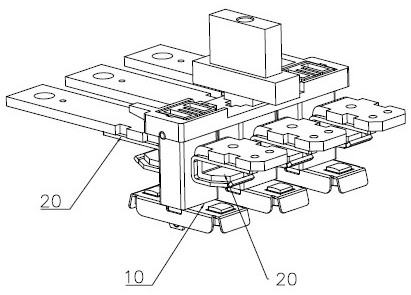

[0022] Such as figure 1 As shown, a contact mechanism includes a correspondingly arranged moving contact assembly 10 and a static contact assembly 20, which is a bridge-type double-break point contact structure.

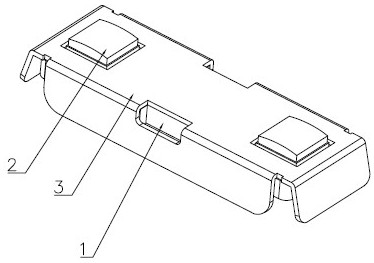

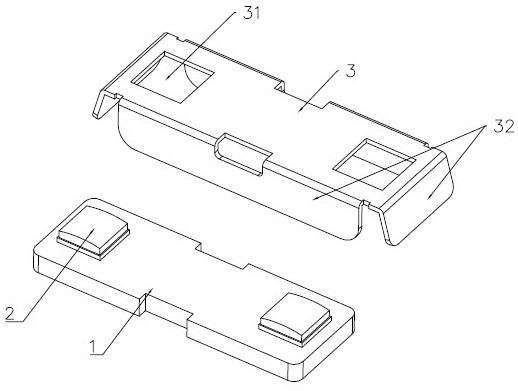

[0023] Such as Figure 2-3 As shown, the moving contact assembly 10 includes a moving contact plate 1, a moving contact 2, and a first arc striker 3; the contact plate 1 is a straight plate structure, and the contacts 2 are arranged on the contact plate 1 At both ends of the surface, the first arc-starting plate 3 is a straight plate structure compatible with the moving contact plate 1, and is installed on the upper surface of the moving contact plate 1, and the first arc-starting plate 3 is made of ferromagnetic material , and the two ends of the first arc starting plate 3 are formed with a first wrapping opening 31 suitable for the contact 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com