Dual-output driving motor for vehicle

A driving motor, dual output technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of high vibration and noise, adsorption to the stator, easy deflection, etc., to achieve low vibration and noise, ensure normal operation, shaft Good for moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

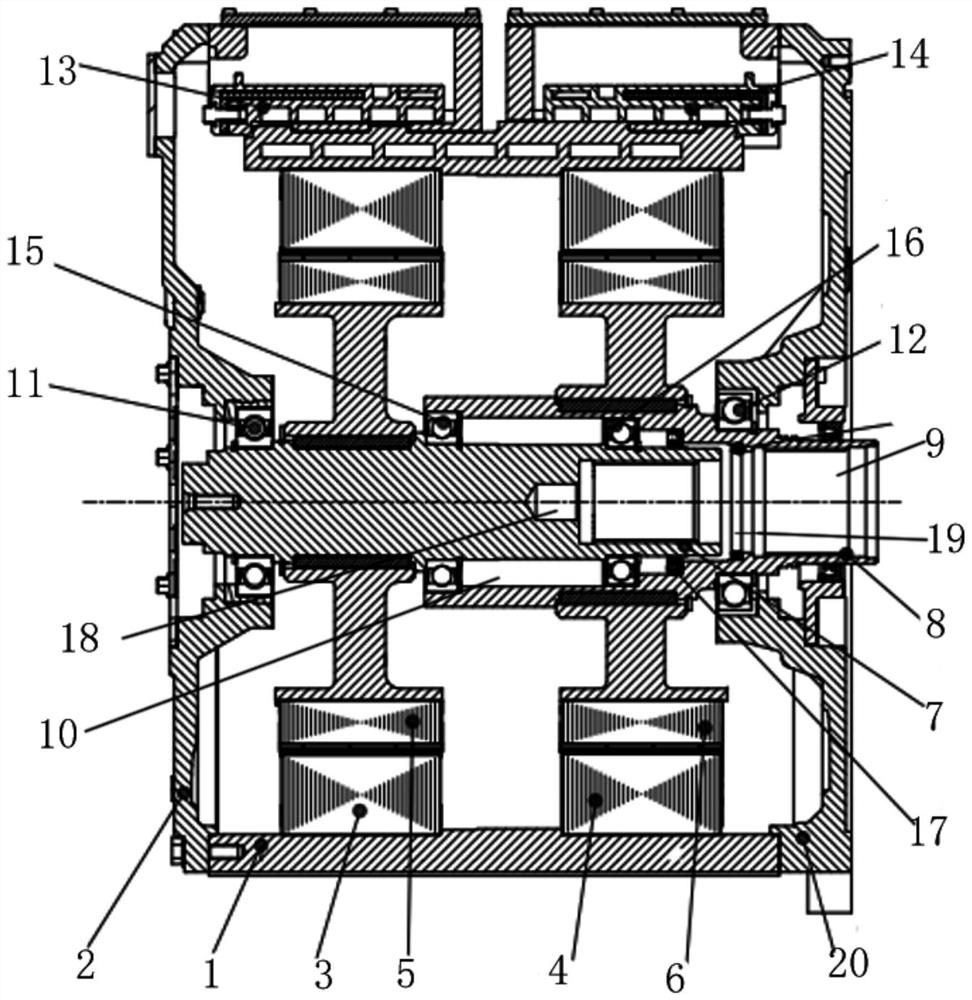

[0026] Specific embodiment one, see figure 1 When the front end cover 2 is specifically a closed end cover, the whole structure is used as a pure electric system to drive the motor.

specific Embodiment 2

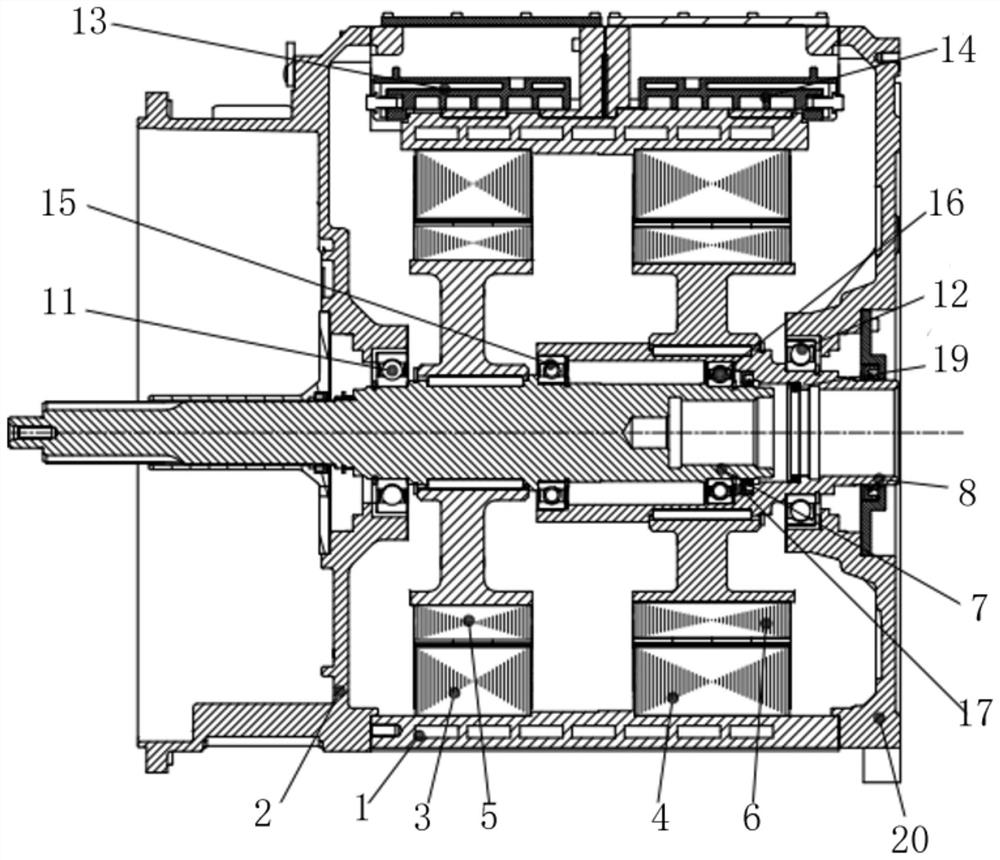

[0027] Specific embodiment two, see figure 2 The structure of the front end cover 2 is specifically in the form of a clutch housing, the first motor shaft protrudes from the end cover, and is used for connecting with a matching engine to form a hybrid power system.

[0028] Its working principle is as follows: the first stator and the second stator share the casing, and they are arranged side by side coaxially along the axial direction; there is no partition between the two stators, and a normal electrical gap is maintained. The second motor shaft is a hollow shaft. The first motor shaft passes through it; in the axial middle of the housing, at least two support bearings are nested between the second motor collar wall and the outer ring surface of the first motor shaft, and the two bearings at the axial start and end There is a large distance between the two support bearings to ensure stable and reliable support. There is no direct rigid connection between the first motor sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com