Sorting, recycling and automatic tying equipment

A kind of equipment and automatic technology, applied in the direction of automatic packaging control, external support, transportation and packaging, etc., can solve the problems of affecting the efficiency of cleaning and transportation, and large manpower and material resources, so as to ensure the effect of risk control, reduce the cost of risk control, and reduce the consumption of manpower and material resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

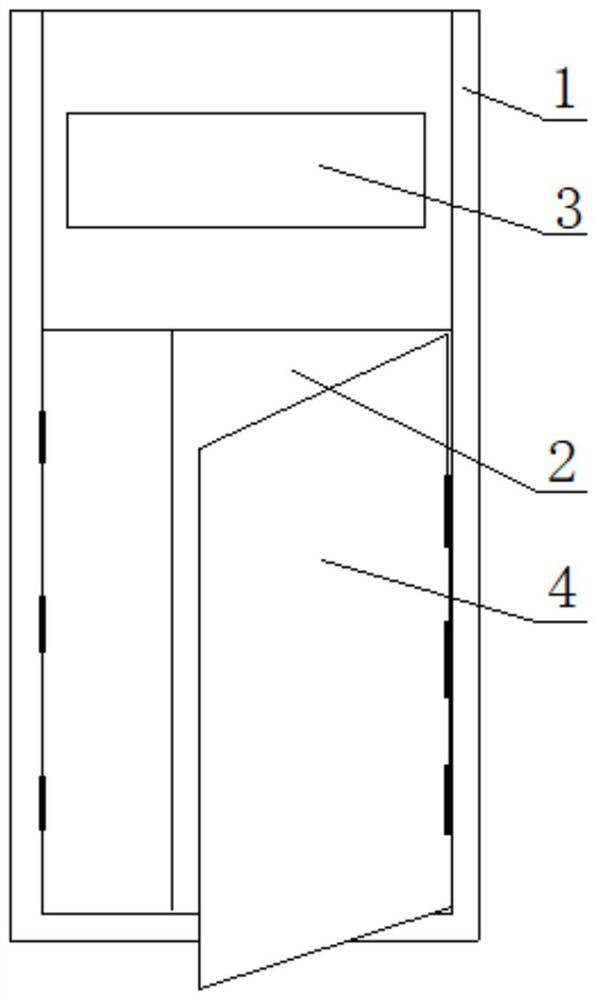

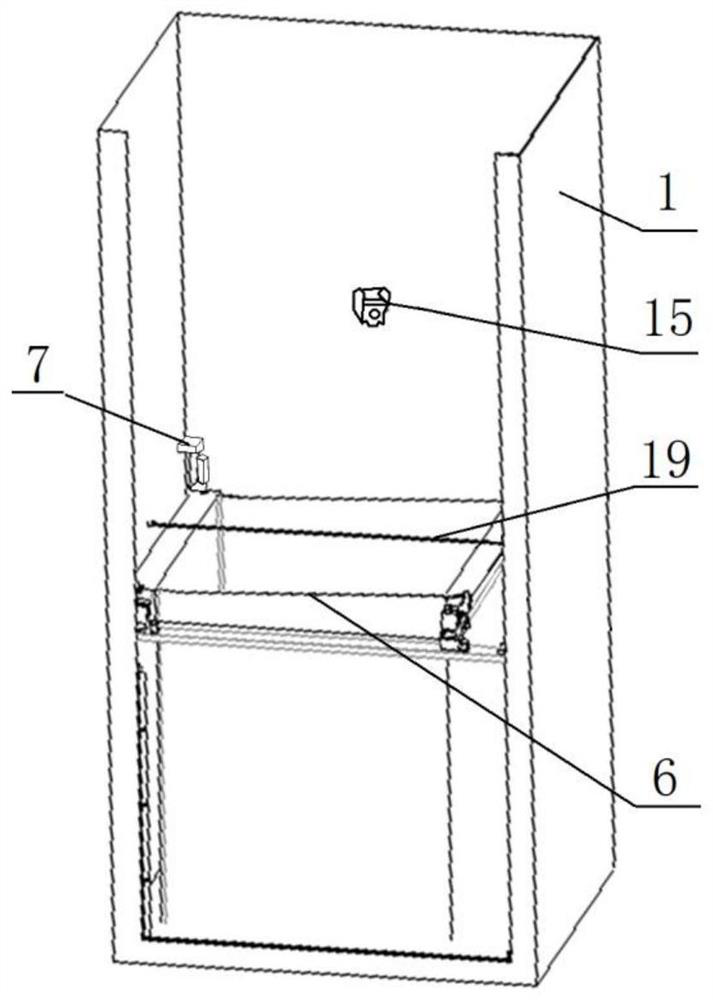

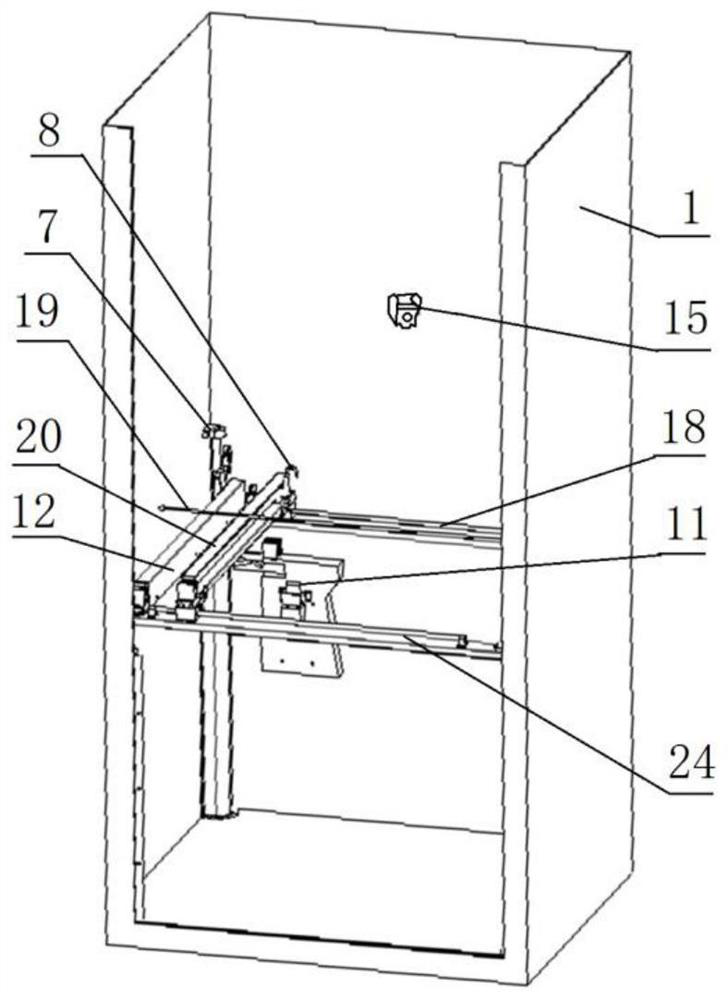

[0033] Example 1: as attached figure 1 to the attached Figure 13 As shown, a sorting and recycling automatic tying device includes a body 1, a folding and sealing frame 10, a tying device 25, a lifting and moving slide rail 13, a first front and rear translation slide rail 12, a second front and rear translation slide rail 20, a first A left and right translation slide rail 18 and a second left and right translation slide rail 24; the lower inner wall of the body 1 is erected to install the lift movement slide rail 13, and the first left and right translation slide rail 18 and the second left and right translation slide rail 18 are horizontally installed on the lower movement slide rail 13. The slide rail 24, the first front and rear translation slide rails 12 and the second front and rear translation slide rails 20 are horizontally installed on the upper sides of the first left and right translation slide rails 18 and the second left and right translation slide rails 24; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com