Multi-stage oil-water separator

An oil-water separator, No. 1 technology, applied in water/sewage multi-stage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of affecting the working efficiency of middle-set equipment and solid waste filtering device drop and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

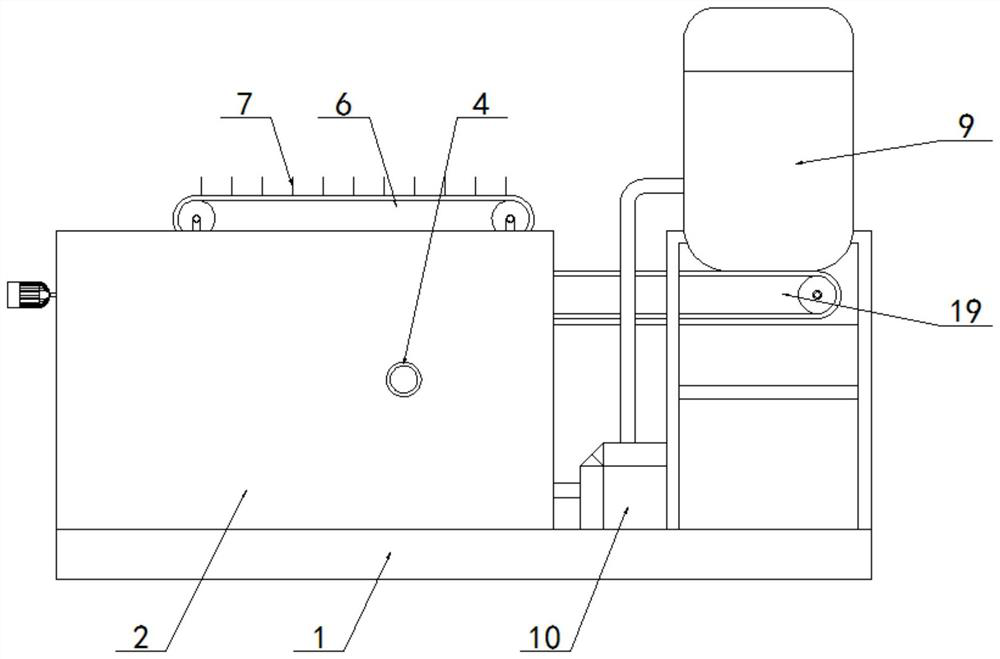

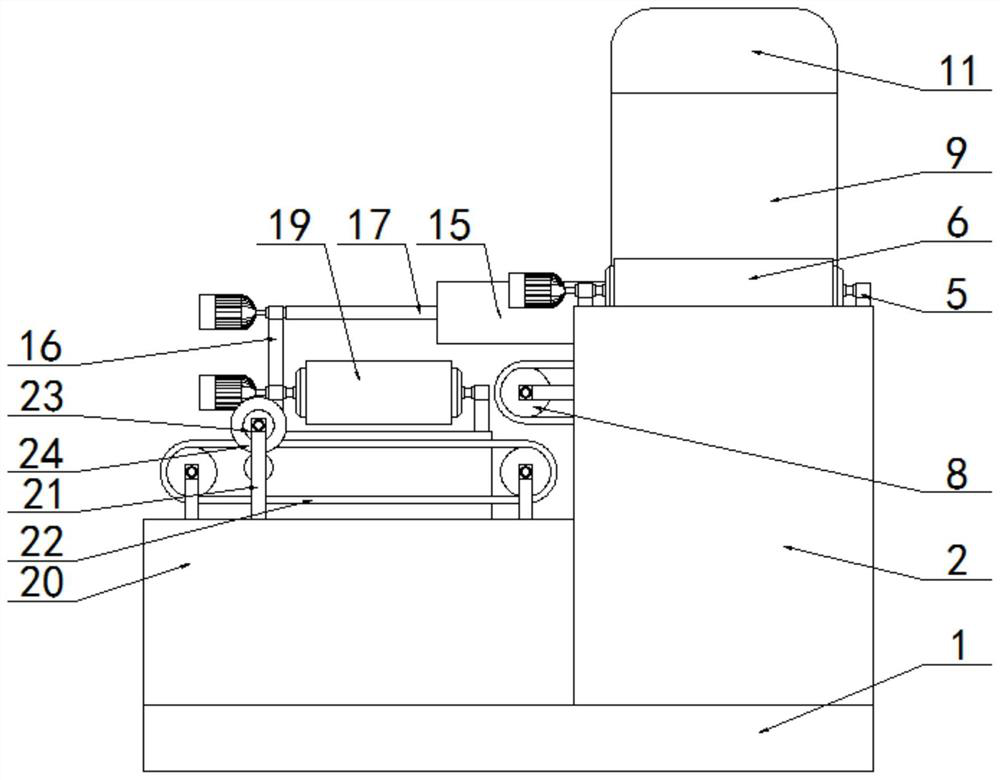

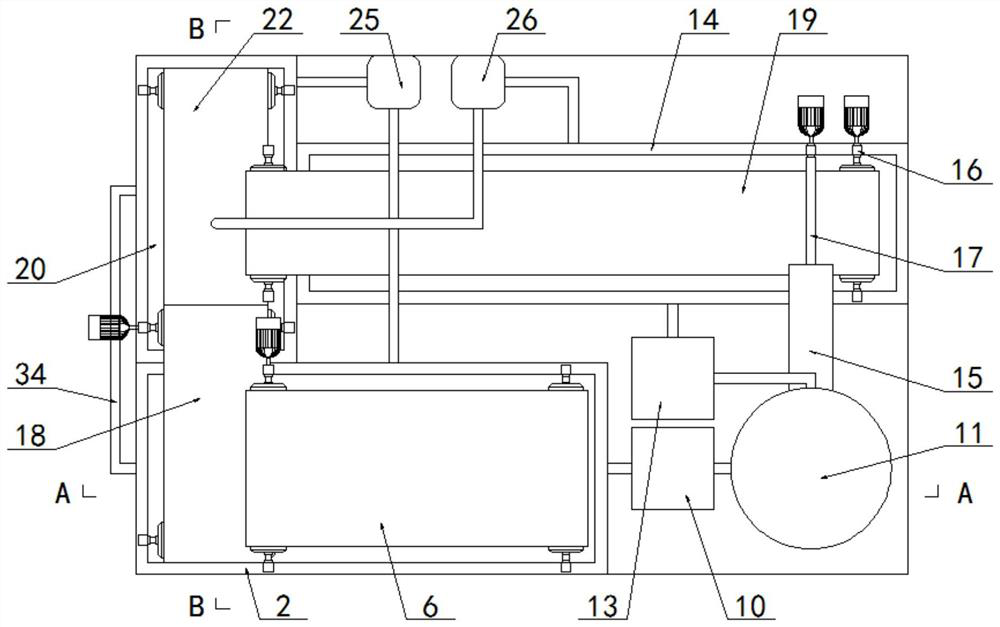

[0027] see as Figure 1-Figure 7 As shown, this specific embodiment includes a base 1, a No. 1 reservoir 2, a No. 1 conveyor belt 6, a No. 2 conveyor belt 8, a pressurized tank 9, an impurity pump 10, and an oil-water separator 13, wherein the base 1 is riveted with a No. 1 Reservoir 2, No. 1 reservoir 2 is riveted with dividing plate 3, riveted with water inlet pipe 4 on No. 1 reservoir 2, and the outlet end of water inlet pipe 4 is arranged on the right side of dividing plate 3, one No. 1 support 5 is riveted on the No. 1 storage tank 2, and No. 1 conveyor belt 6 is riveted on the No. 1 bracket 5. The drive shaft of No. 1 conveyor belt 6 is provided with a driving motor, and the left end of No. 1 conveyor belt 6 is arranged on the left side of partition plate 3. On the side, the belt surface of the No. 1 conveyor belt 6 is riveted with grasping teeth 7, and the No. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap