Track comprehensive detection and diagnosis method

A technology of comprehensive detection and diagnosis methods, applied in the field of rail construction machinery, can solve the problems of low degree of intelligence and single detection method, and achieve the effect of reducing manual participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

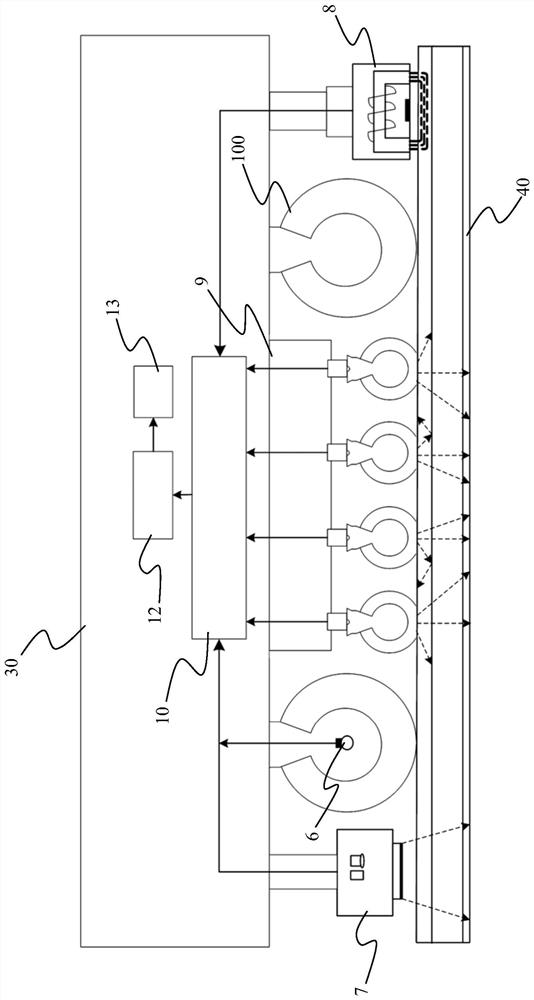

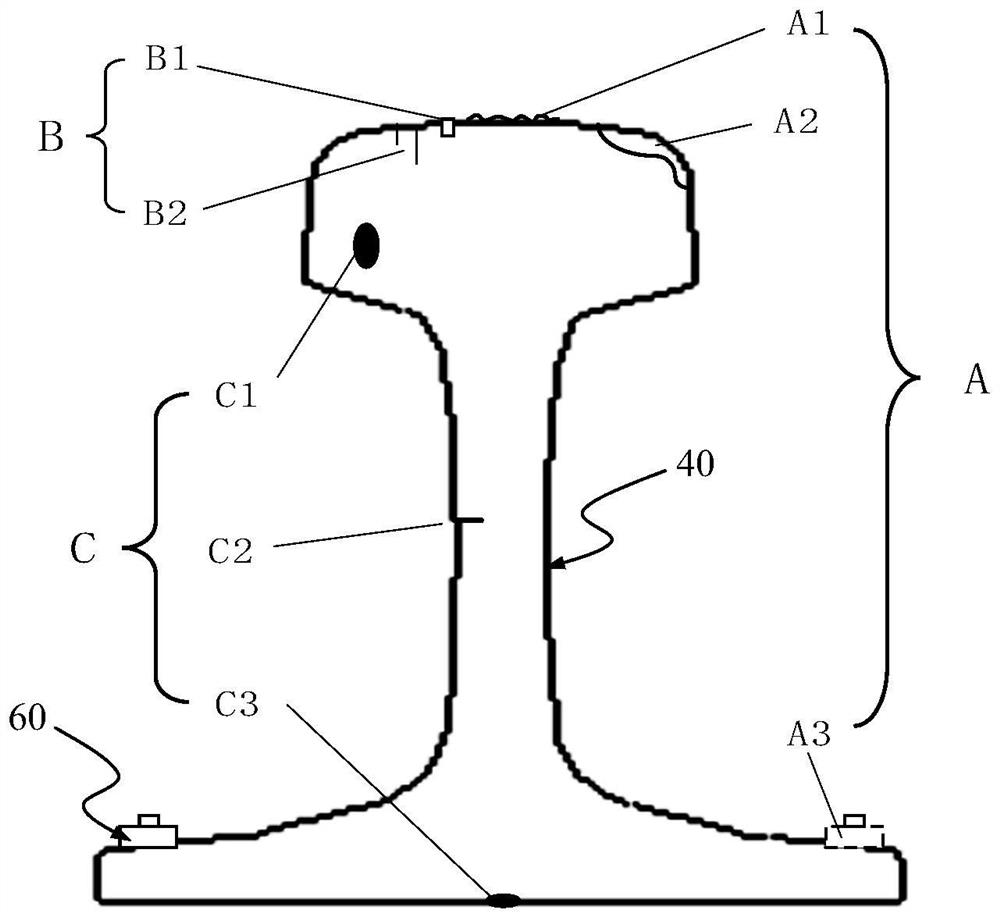

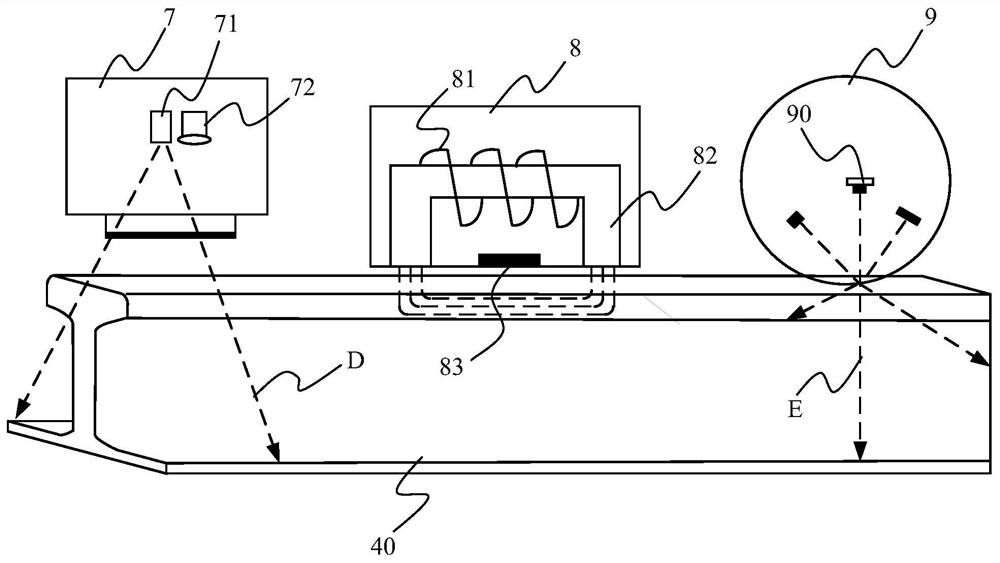

[0059] as attached figure 1 As shown, an embodiment of the track comprehensive detection and diagnosis system based on the method of the present invention specifically includes: a front-end sensing component 20 , a damage detection signal processing component 10 and an intelligent identification processing computer 12 connected in sequence. First, the front-end sensing component 20 completes the excitation of original sensing signals of all channels and the collection of feedback signals. Secondly, the damage detection signal processing component 10 in the middle layer completes the acquisition and parallel processing of the sensor feedback signals of each channel, and uses the architecture of real-time controller + new high-speed data bus to manage, control and target the sensor feedback signals of each channel in real time. Result data processing. Finally, the top-level intelligent recognition processing computer 12 performs intelligent recognition processing on the data ou...

Embodiment 2

[0076] as attached Figure 9 As shown, an embodiment of the track comprehensive detection and diagnosis method of the present invention specifically includes the following steps:

[0077] S11) The front-end sensing component 20 performs excitation of original sensing signals of all channels and collection of feedback signals;

[0078] S12) The damage detection signal processing component 10 performs the acquisition and parallel processing of the sensor feedback signals of each channel, and performs real-time management, control and target result data processing of the sensor feedback signals of each channel;

[0079] S13) Intelligent recognition processing The computer 12 performs intelligent recognition processing on the data output by the damage detection signal processing component 10, and completes the calculation, processing and dynamic output of the final damage data.

[0080] The front-end sensor assembly 20 further includes a speed encoder 6 , a camera sensor device 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com