Mounting and fixing box for BMS new energy battery

A new energy and fixed box technology, applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve the problems of affecting the service life, easy to shake batteries, damage, etc., and achieve the effect of efficient heat dissipation and convenient transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

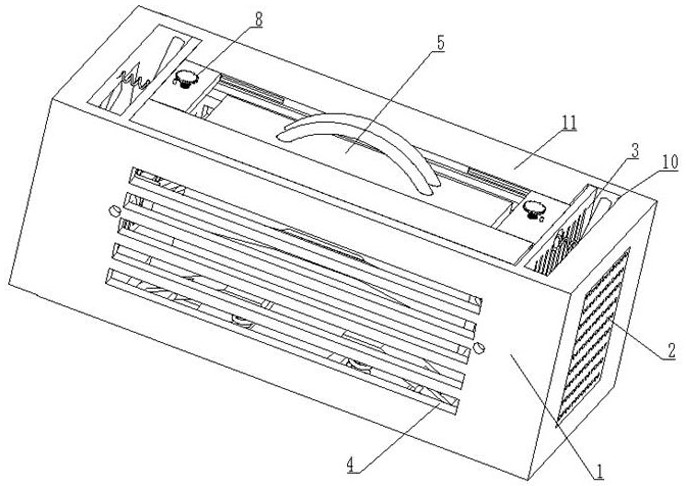

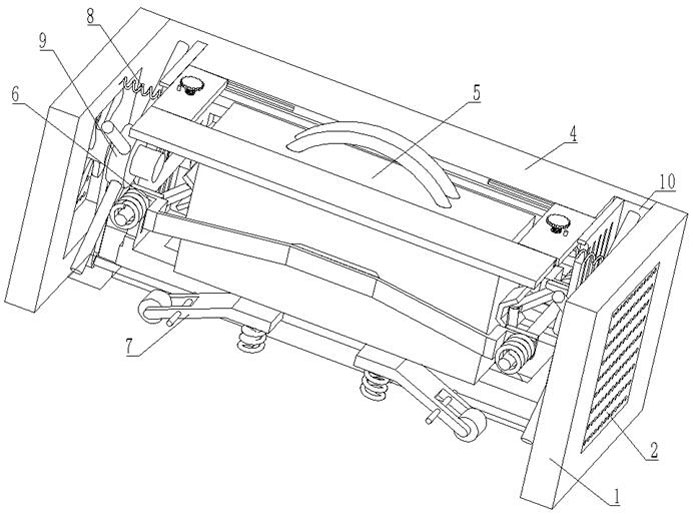

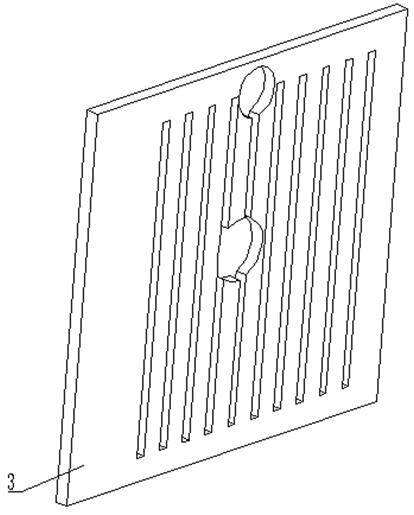

[0033] see Figure 1-5 , a BMS new energy battery installation and fixing box, including a chassis 1, a filter screen 2 is fixedly installed on both sides of the chassis 1, the front and rear of the chassis 1 are provided with ventilation grooves 4, and the inside of the chassis 1 is provided with The device slot 10, the inner wall of the device slot 10 is fixedly connected with the heat dissipation plate 3, the inside of the cabinet 1 is provided with a battery body 5, the upper surface of the cabinet 1 is welded with a fixing plate 11, and the inside of the fixing plate 11 is provided with a fixing mechanism 8, the cabinet 1 A buffer mechanism 6 is provided inside the case 1, a moving mechanism 7 is provided at the bottom of the case 1, and a heat dissipation device 9 is provided at the bottom of the case 1.

[0034] In this embodiment, the buffer mechanism 6 includes a fixed slide bar 61, the surface of the fixed slide bar 61 is slidably connected with two slide plates 63, ...

Embodiment 2

[0040] see Figure 6-7 , the fixing mechanism 8 includes a sliding support plate 85, the bottom of the sliding support plate 85 is welded with a connecting plate 84, the right side of the connecting plate 84 is welded with a cover spring 81, and the right end of the cover spring 81 passes through the cooling plate 3 and is connected to the chassis 1 is fixedly connected to the inner wall, the surface of the fixed plate 11 is provided with a chute 87, the surface of the sliding support plate 85 is slidably connected to the inner wall of the chute 87, and the connecting plate 84 will be pushed by the cover spring 81, and the connecting plate 84 will be Push the sliding support plate 85 to slide inward, which will drive the pressing block 83 to press on the upper surface of the battery, so as to realize the overall automatic fixing effect of the battery, so that the battery will not fall and slide out inside the chassis 1, and improve the stability of the battery. stability.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com