A method and device for cascading and grouping soft pack batteries

A technology for cell packs and soft packs, applied in battery pack components, circuits, electrical components, etc., can solve the problems of long welding time, cumbersome operation, and needs to be improved, so as to shorten the welding time, improve production efficiency, and improve the welding process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

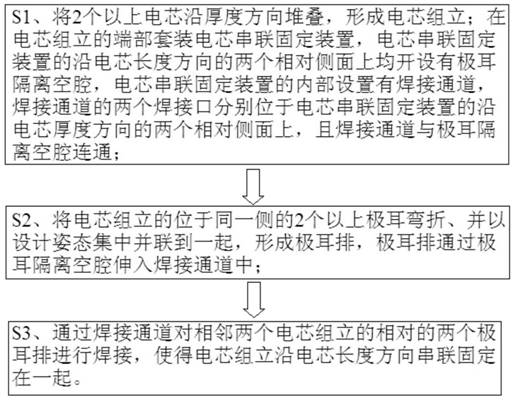

[0078] see figure 1 , a method for cascading and grouping soft-packed cells, comprising the following steps:

[0079] S1. Stack more than two soft-packed cells in the thickness direction to form a soft-packed cell assembly; set a soft-packed cell series fixing device at the end of the soft-packed cell assembly, and the soft-packed cell series fixing device Tab isolation cavities are opened on two opposite sides along the length direction of the soft-packed cells, and a welding channel is arranged inside the series-fixing device of the soft-packed cells, and the two welding ports of the welding channel are respectively located in the series of the soft-packed cells. On two opposite sides of the fixing device along the thickness direction of the soft-covered electric core, the welding channel is communicated with the tab isolation cavity.

[0080]Specifically, since the method of cascading and grouping soft-packed cells in the present invention is to centrally connect the tabs ...

Embodiment 2

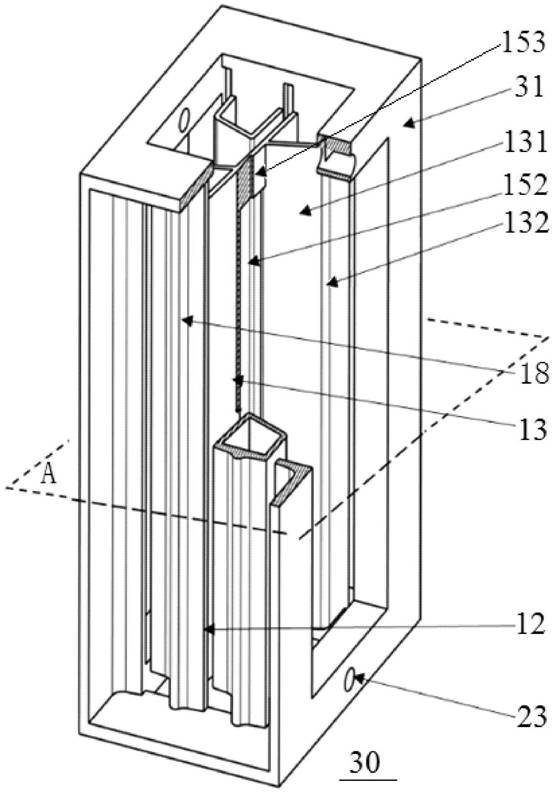

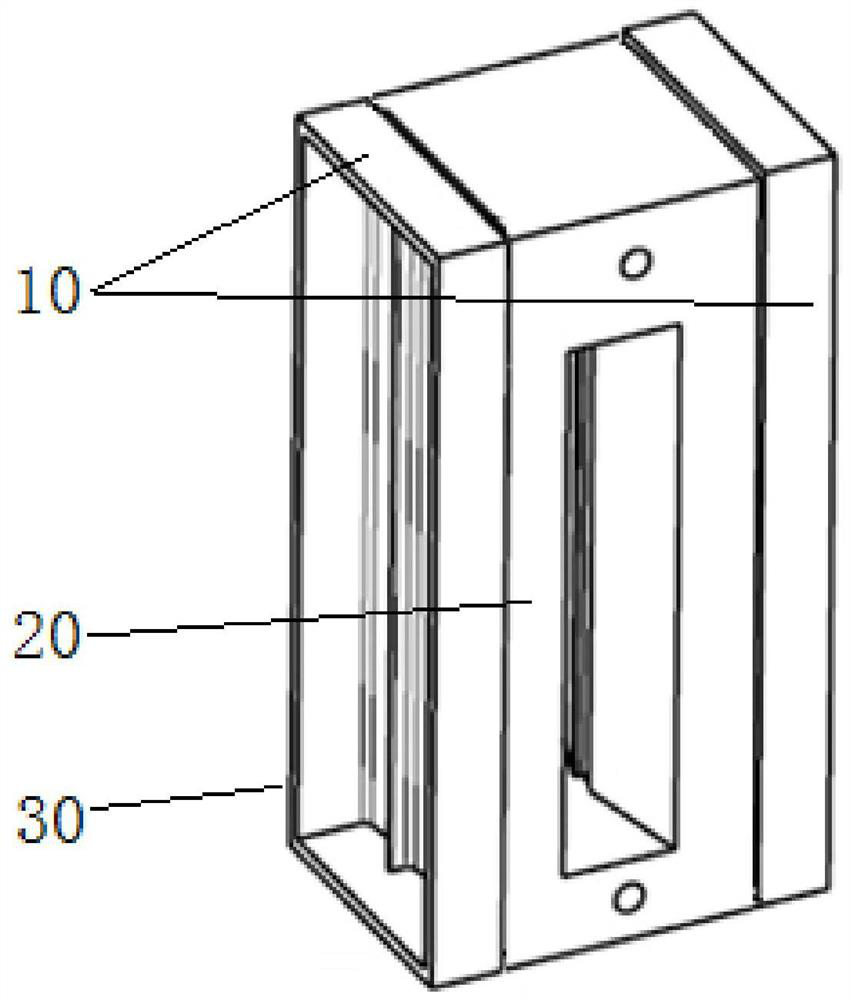

[0088] Based on the same inventive concept, this embodiment provides an apparatus for implementing the method for cascading and grouping soft-packed cells in the above-mentioned Embodiment 1. The apparatus includes a series-fixing device for soft-packed cells, the structure of which is as follows: figure 2 and image 3 As shown in the figure, in this embodiment, the series fixing device for soft-packed cells adopts a split structure, including a pole ear opposite fixing block 20 and two pole ear limit plates 10, and the two pole ear limit plates 10 are respectively arranged on The tabs are opposite to both sides of the fixing block 20 , and the tab limiting plate 10 is detachably connected to the opposite fixing block 20 .

[0089] Specifically, the structure of the pole ear limiting plate 10 is as follows Image 6 and Figure 7 As shown, the main body includes a base 11, and the base 11 is provided with two or more parallel tab through holes 12 and tab guide surfaces 13 wi...

Embodiment 3

[0115] Based on the same inventive concept, this embodiment provides another device for implementing the method for cascading and grouping soft-packed cells in the above-mentioned embodiment 1. The apparatus includes a series-fixing device for soft-packed cells, the structure of which is as follows: Figure 12 to Figure 15 As shown, in this embodiment, the series fixing device for soft-packed cells adopts an integrated structure, and the series-fixing device 30 for soft-packed cells includes a base body 31, which is a symmetrical structure as a whole, and two opposite sides of the base body 31 are provided with There are two or more parallel tab through holes 12 and the same number of tab guide surfaces 13 as the number of tab through holes 12 . The tab through hole 12 and the tab guide surface 13 should be arranged on the side of the soft-packed cell series fixing device 30 in contact with the soft-packed cell, so as to ensure that the soft-packed cell tab passes through the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com