Lithium battery electrode connecting process

A lithium battery and electrode technology, which is applied in the field of lithium battery electrode connection technology, can solve problems such as high welding cost, human injury, and easy splashing of welding slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

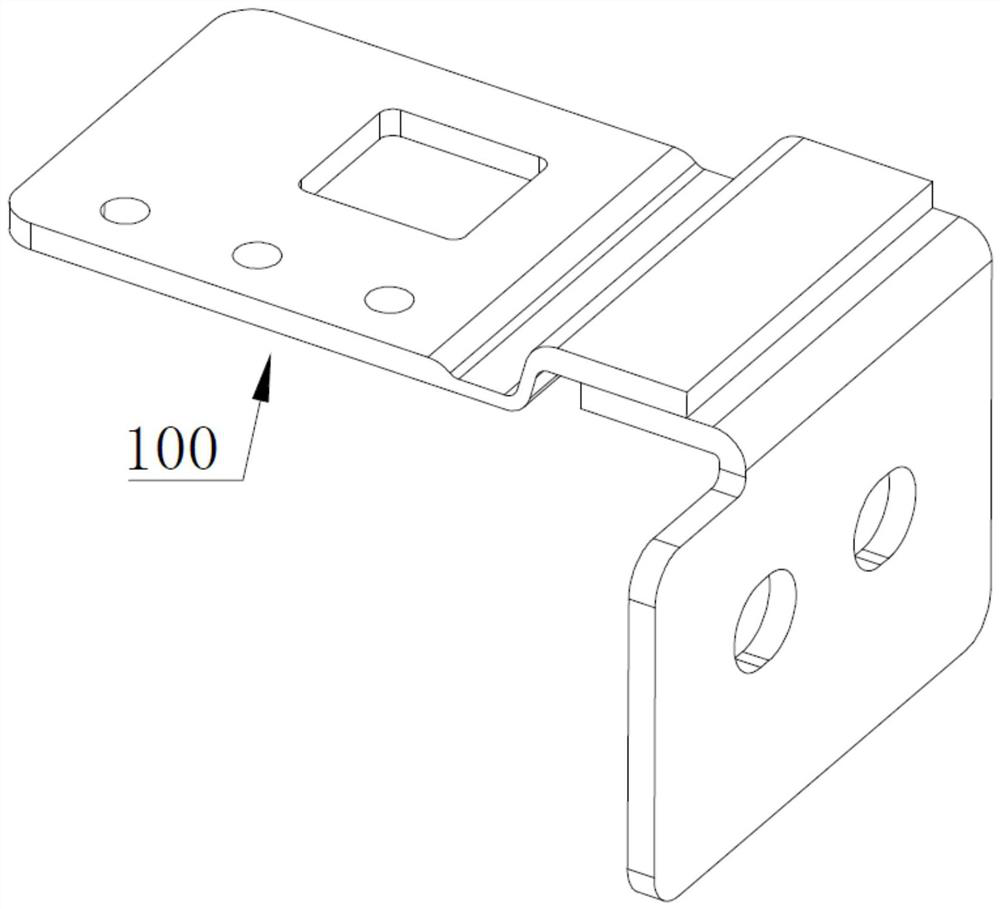

[0023] like Figure 1 ~ Figure 2 As shown, a lithium battery electrode connection process, including electrode poles;

[0024] The lithium battery electrode connection process includes the following steps:

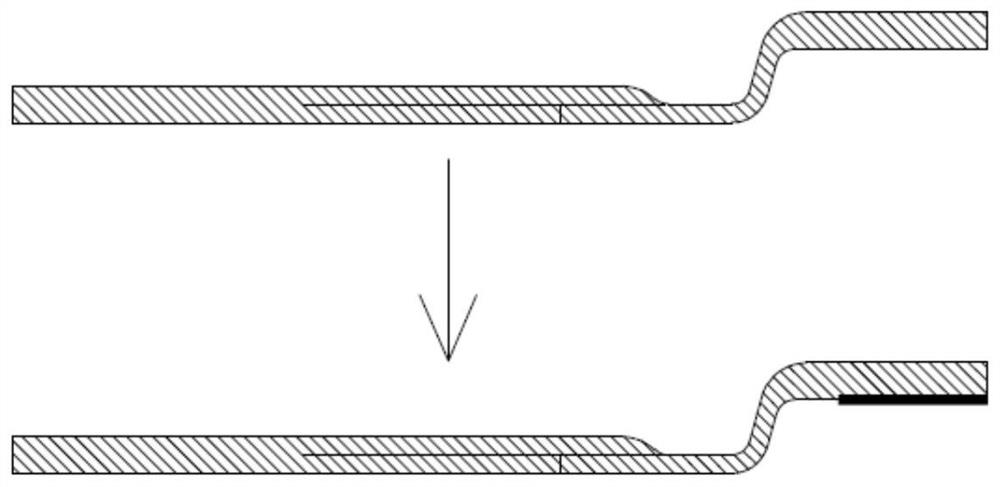

[0025] S1, processing and forming the electrode pole;

[0026] S2, cleaning the electrode pole to form a spraying position;

[0027] S3, spraying a spray layer on the surface of the spraying position.

[0028] The electrode pole 100 is based on an aluminum sheet, an aluminum alloy sheet, a copper sheet or a copper-aluminum composite sheet, which is selected according to the heat dissipation environment. Generally, it is an aluminum plate or an aluminum alloy plate, which has good heat conduction and heat dissipation performance.

[0029] In step S3, the electrode pole 100 is an aluminum or aluminum alloy sheet; the sprayed material is sprayed on the surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com