Device and method for determining absolute reference zero point of high-precision motor

A determination device, high-precision technology, applied in the direction of motor control, electrical components, control systems, etc., can solve the problem of not meeting the accuracy requirements, achieve the effect of low error rate, overcome the non-unique detection zero position, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

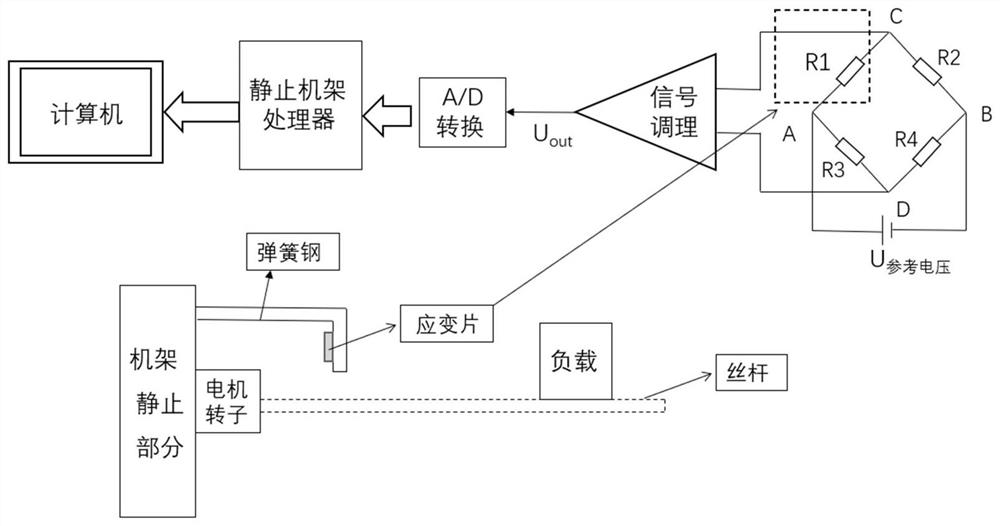

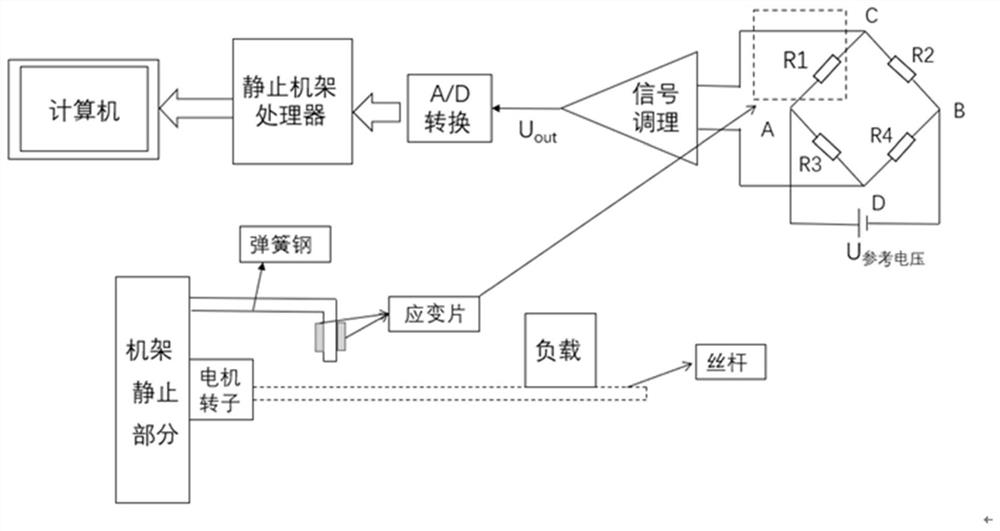

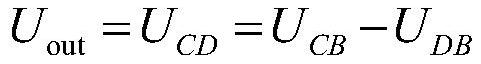

[0038] like figure 2 As shown in the figure, two strain gauges are installed on both sides of the spring steel and connected to the first and second bridge arms of the circuit. When the load contacts the spring steel, the resistance values of the strain gauges of the first and second bridge arms both occur. change, R 1 becomes R 1 -ΔR 1 , R 2 becomes R 2 -ΔR 2

[0039] Set the reference voltage U 参考电压 =5V, R 1 =R 2 =R 3 =R 4 =120Ω, ΔR 1 = 20Ω, ΔR 2 =19Ω, when the object is at the zero position, the resistance R of the strain gauge 1 at this time 1 -ΔR 1 =120Ω-20Ω=100Ω, resistance R of strain gauge 2 2 -ΔR 2 =120Ω-19Ω=101Ω, so

[0040] The magnification of the signal conditioning circuit is set to 100 times (according to the actual measured voltage range, adjust the magnification of the signal conditioning circuit so that the sampled voltage value is within an appropriate range and the accuracy can be improved), so when the motor is at zero, At this tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com