Homogenizing device for poultry feeding

The technology of a homogenizing device and poultry is applied in the field of poultry breeding, which can solve the problems of easy pressure bonding of the feed layer, and achieve the effects of improving the flexibility of feeding, being beneficial to growth and development, and increasing the output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] According to the above structure characteristics of the present application, the embodiments of the present application will be further explained:

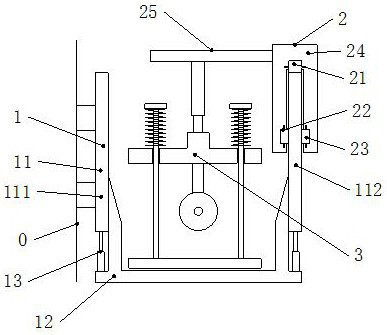

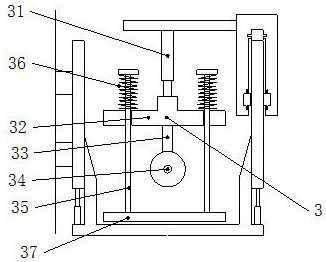

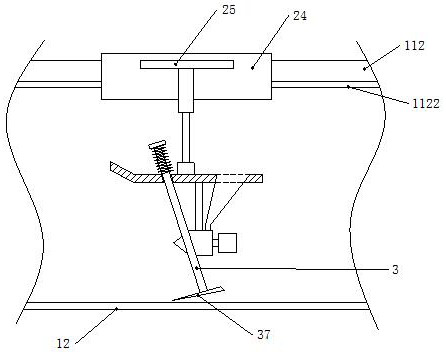

[0024] Refer Figure 1 ~ 6 In this embodiment, the present embodiment provides a poultry feeding uniform material, including the groove 1, the drive mechanism 2, the uniform material 3 and the PLC controller, the groove 1 includes a side plate 11, the bottom plate 12 and the first pusher 13, side The plate 11 includes a first side plate 111 and a second side plate 112, and the first side plate 111 is opposite to the second side plate 112, and the bottom plate 12 is U-shaped; the side surface of the first side plate 111 and the bottom plate 12 The first pusher 13 is slid, and the inner side surface of the second side plate 112 is slidably connected to the outer side surface of the bottom plate 12; the first push rod 13 is connected to the PLC controller; the second side plate 112 top surface The first rack structure 1121 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com