High-performance composite fiber fabric and preparation method thereof

A composite fiber and high-performance technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problem of reducing the processing efficiency of hot-melt adhesive film laminating machines, reducing the performance of hot-melt adhesive film laminating machines, Lack of auxiliary feeding mechanism and other issues to achieve the effect of improving the safety of use, ensuring accuracy and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

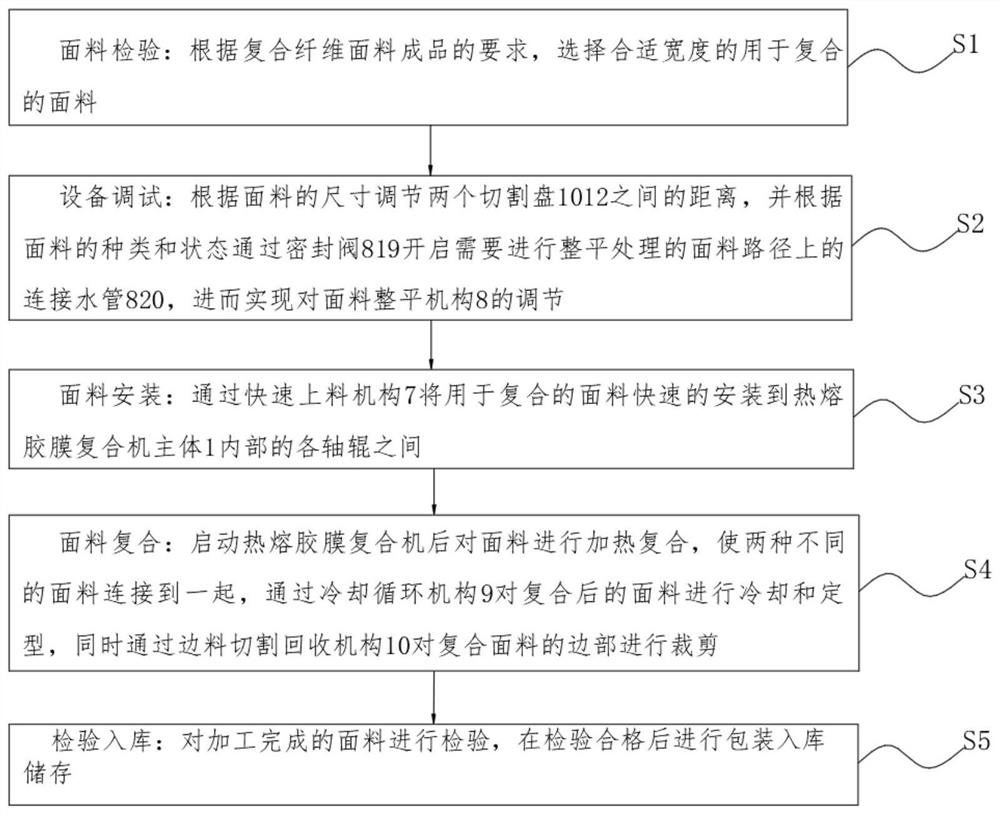

[0044] Example: such as figure 1 As shown, the present invention provides a kind of technical scheme, a kind of preparation method of high-performance composite fiber fabric, comprises the steps:

[0045] S1. Fabric inspection: According to the requirements of the finished composite fiber fabric, select a suitable width for composite fabric;

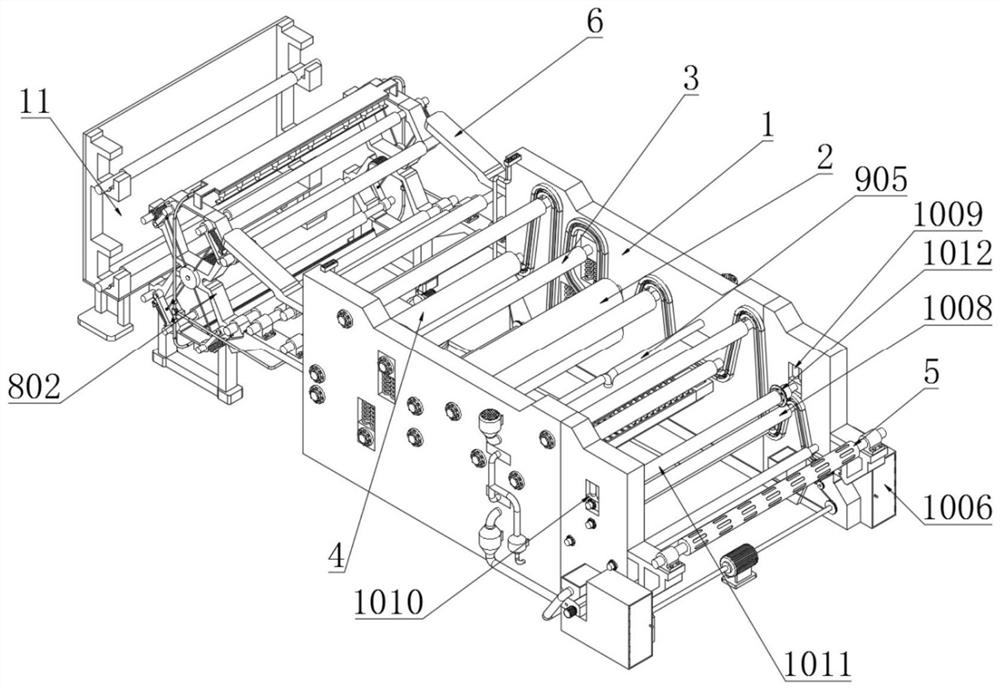

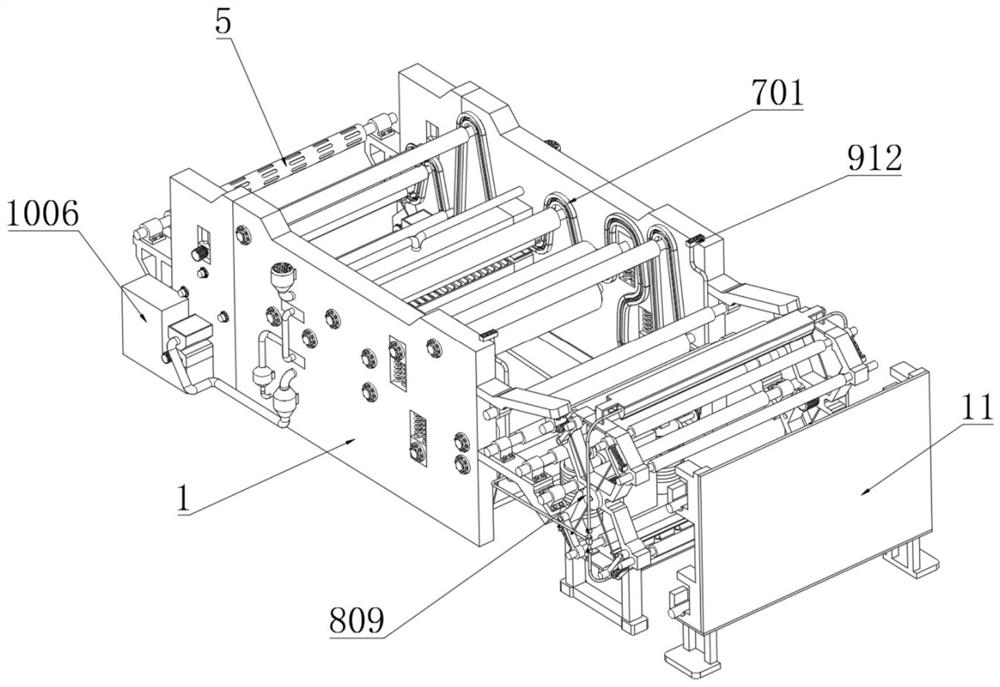

[0046] S2. Equipment debugging: adjust the distance between the two cutting discs 1012 according to the size of the fabric, and open the connecting water pipe 820 on the fabric path that needs to be leveled through the sealing valve 819 according to the type and state of the fabric, so as to realize the adjustment of the fabric Adjustment of leveling mechanism 8;

[0047] S3, fabric installation: quickly install the fabric used for compounding between the shafts and rollers inside the main body 1 of the hot melt adhesive film compounding machine through the fast feeding mechanism 7;

[0048] S4. Fabric compounding: heat and compound th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com