Forming tool for satellite reflector composite central retaining ring

A technology of composite materials and forming molds, applied in the field of fixed ring forming molds, can solve the problems of complex assembly process and RTM glue injection can not be realized, and achieve the effect of reducing the amount of negative glue used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

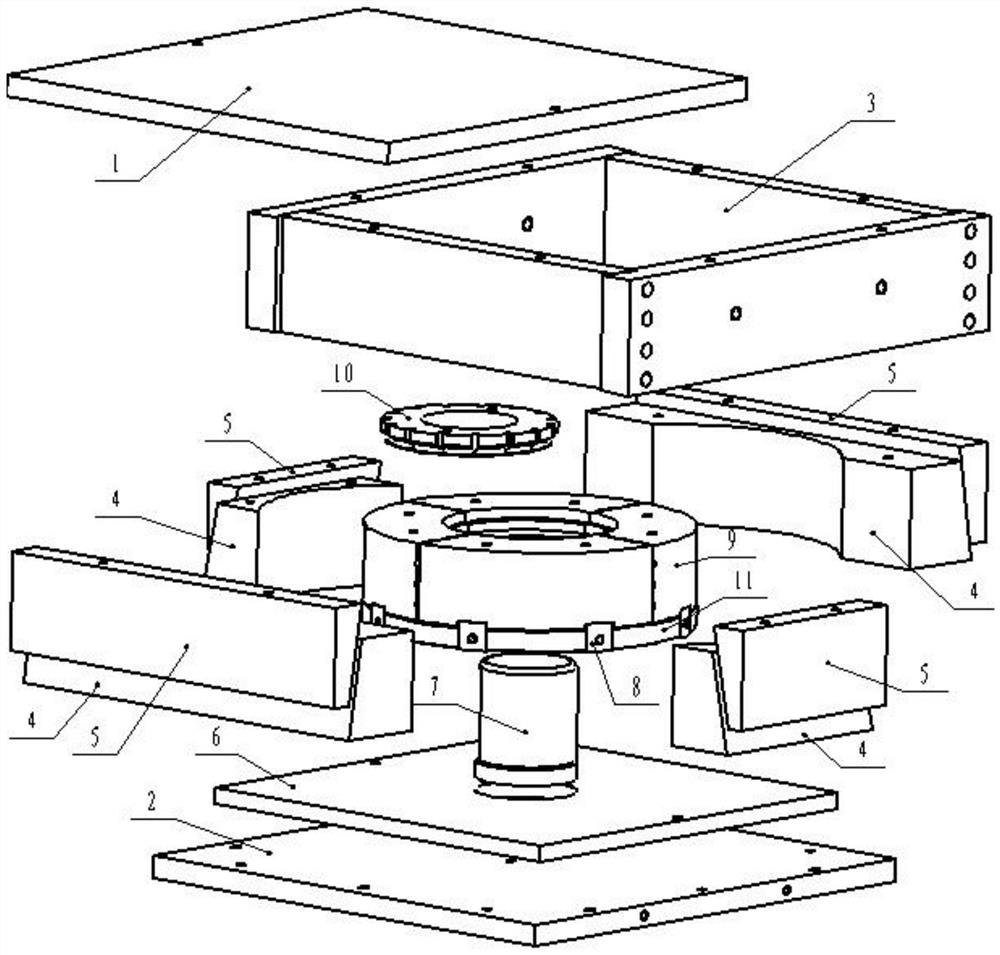

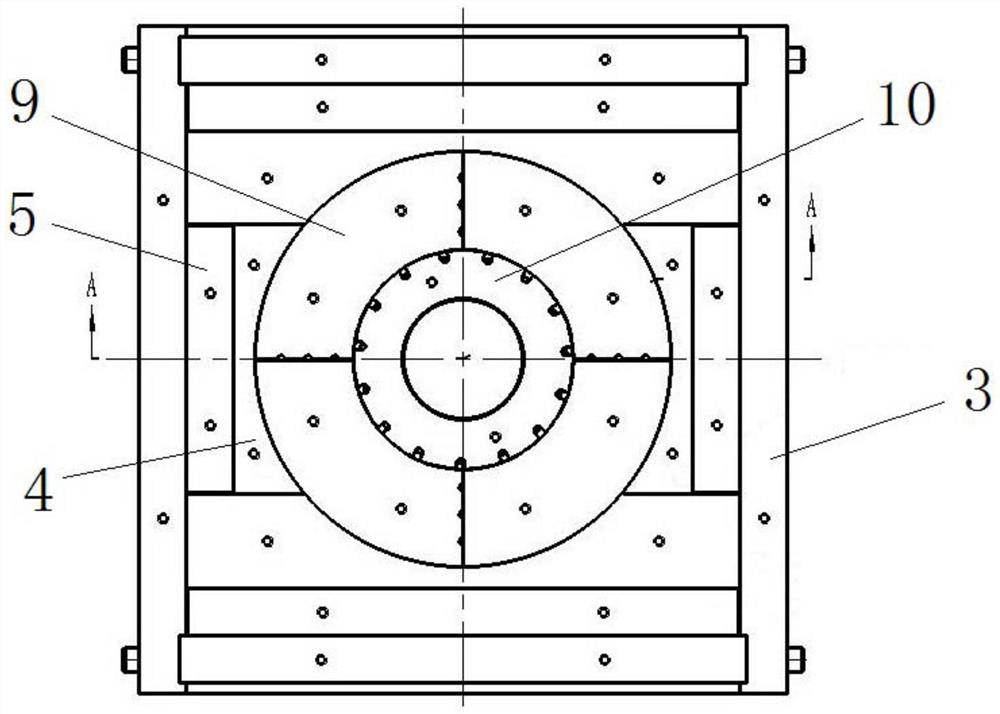

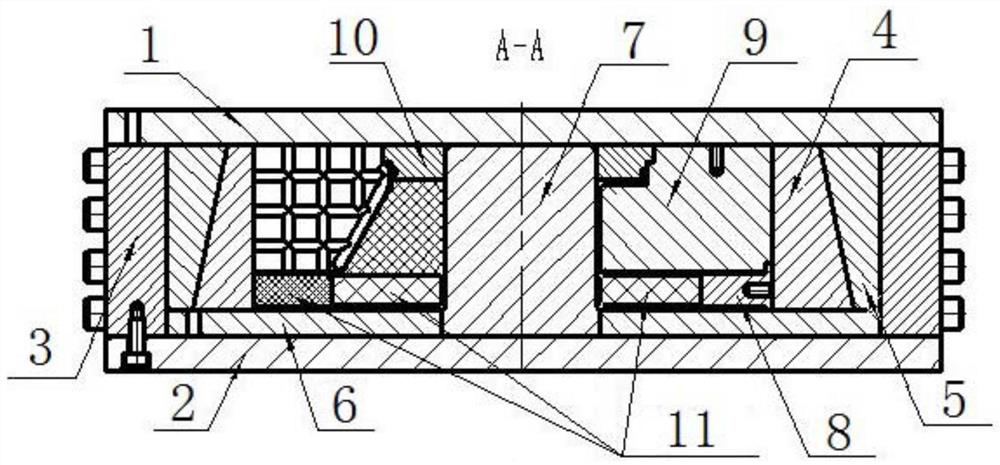

[0034] The embodiment of the present invention will be described in detail below: This example is implemented in the preparation of the present invention, and the detailed embodiment and the specific operation process are given. It should be noted that in terms of ordinary skill in the art, several deformations and modifications can be made without departing from the concept of the present invention, which belongs to the scope of the present invention.

[0035] It is an object of the present invention to provide an integral design method suitable for satellite reflector composite material, and a mold is used as a positioning reference, and the expansion soft mold 11 is pressurized as an incubation; The board is made as the main positioning base. The next flora middle step is used in the overall soft mode 11. The lower flanges and the middle flanges are fixed to the middle flange block, and clearly steel The design method of the mold side soft mold 11, the upper francifier and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com