Rapid automatic straight strip profiling equipment based on machining

A technology of mechanical processing and straight bar pressing, which is applied in the direction of metal processing equipment, manufacturing tools, feeding devices, etc., and can solve the problems of not having longitudinal bending function, unfavorable straight bar pressing, and side bending that cannot be straight, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

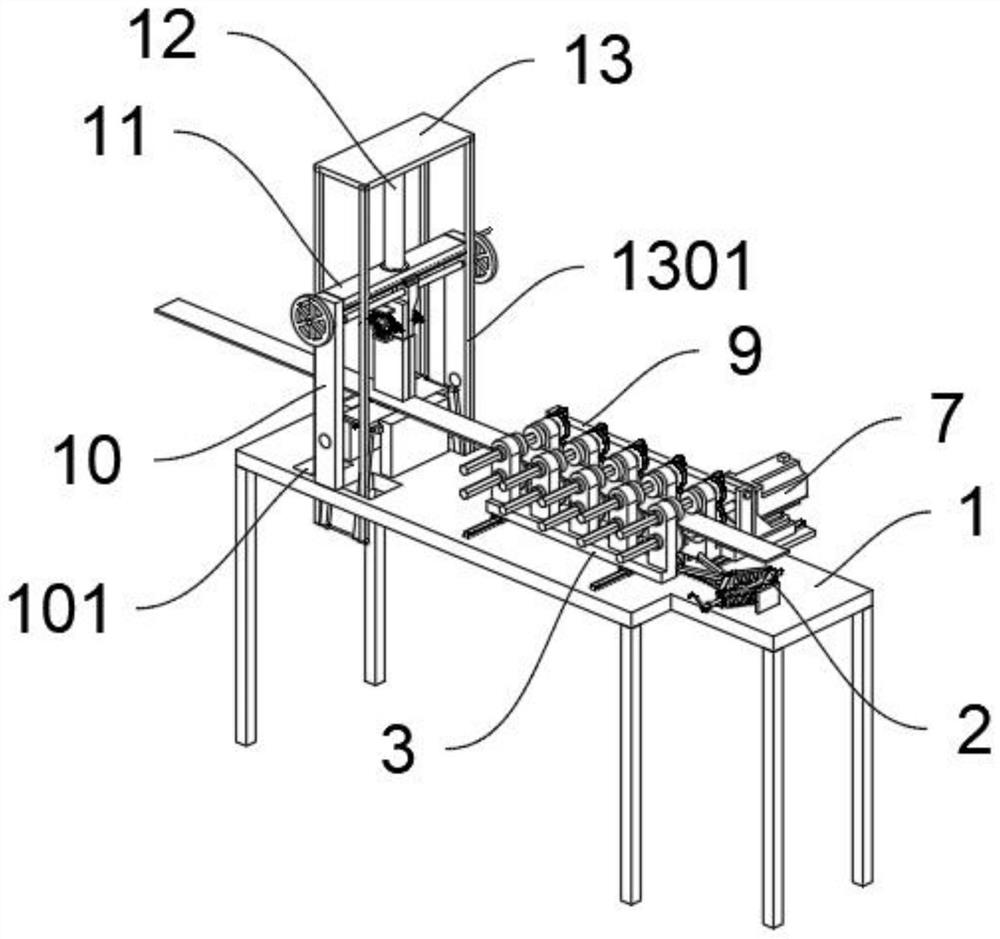

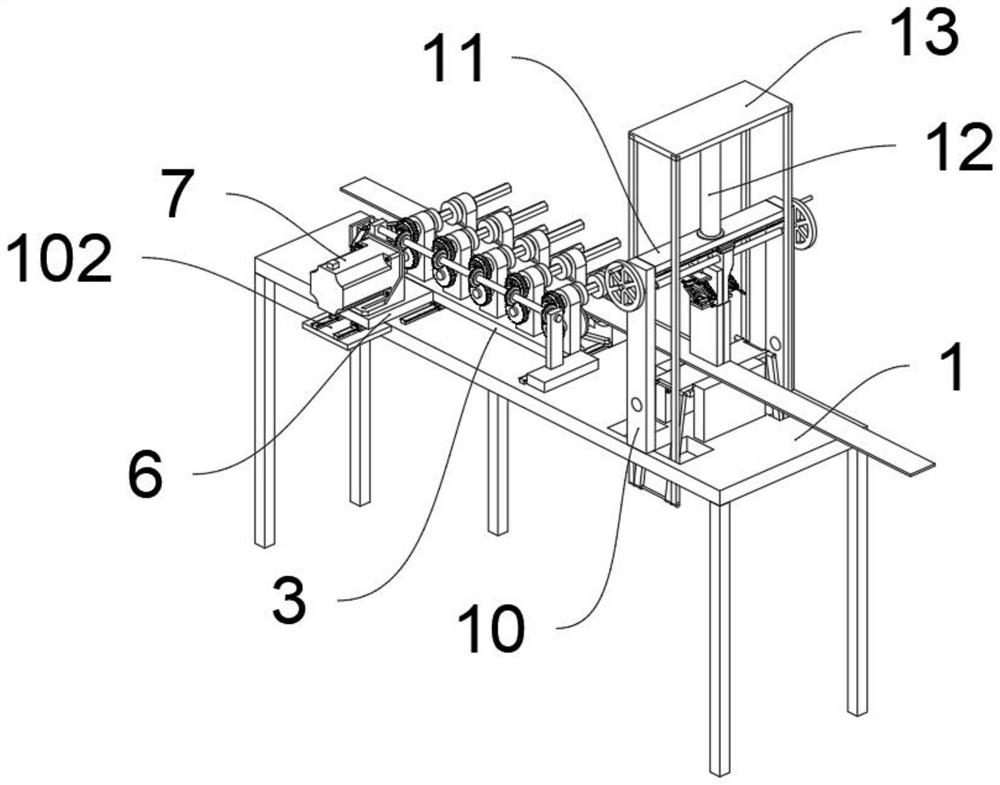

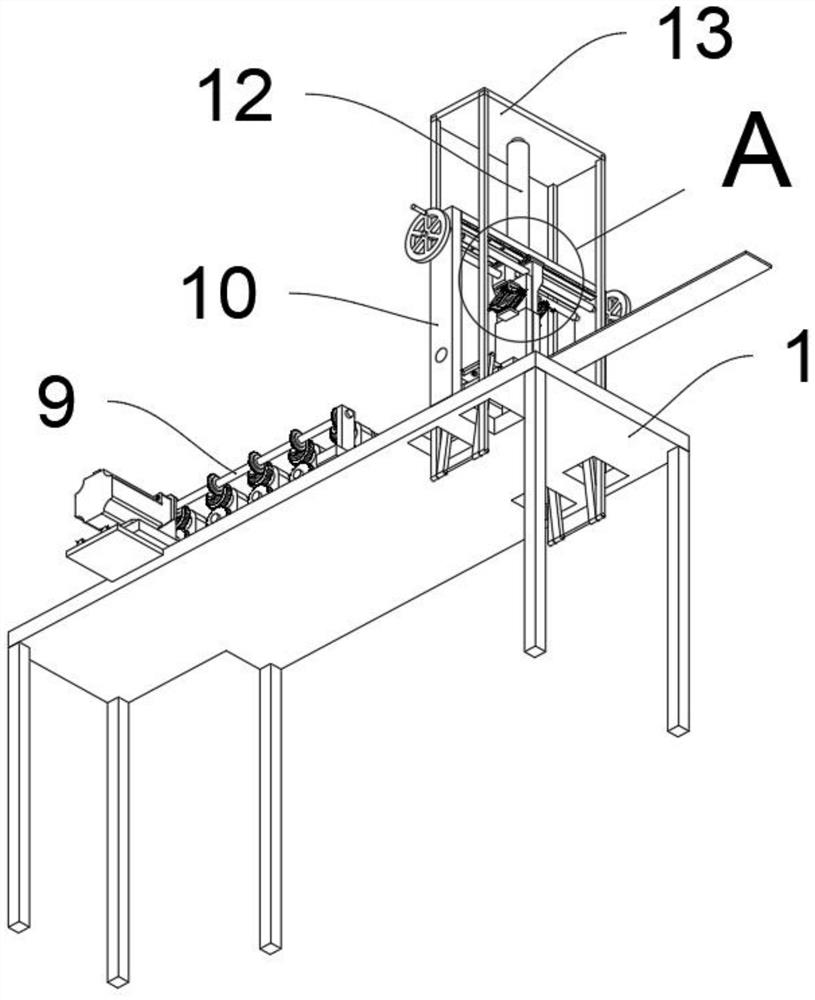

[0032] see Figure 1 to Figure 9, an embodiment provided by the present invention: a fast automatic straight strip profiling equipment based on mechanical processing, including a workbench 1; the front end of the workbench 1 is integrally provided with a vertical plate, and the rear side of the vertical plate is fixedly provided with scissors Adjuster A2; the front side of the top of the workbench 1 is provided with two groups of axle frame rows 3 through guide rail lateral sliding; wherein, the axle frame row 3 also includes a axle frame 301, a connecting rod 302, and a connecting piece 303; the axle frame row 3 Five groups of shaft frames 301 are integrally arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com