Automatic gluing machine with high gluing quality

A viscose machine, viscose technology, applied in container manufacturing machinery, rigid/semi-rigid container manufacturing, paper/cardboard containers, etc., can solve the problems of increasing the burden on staff and low work efficiency, and improve the viscose effect , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

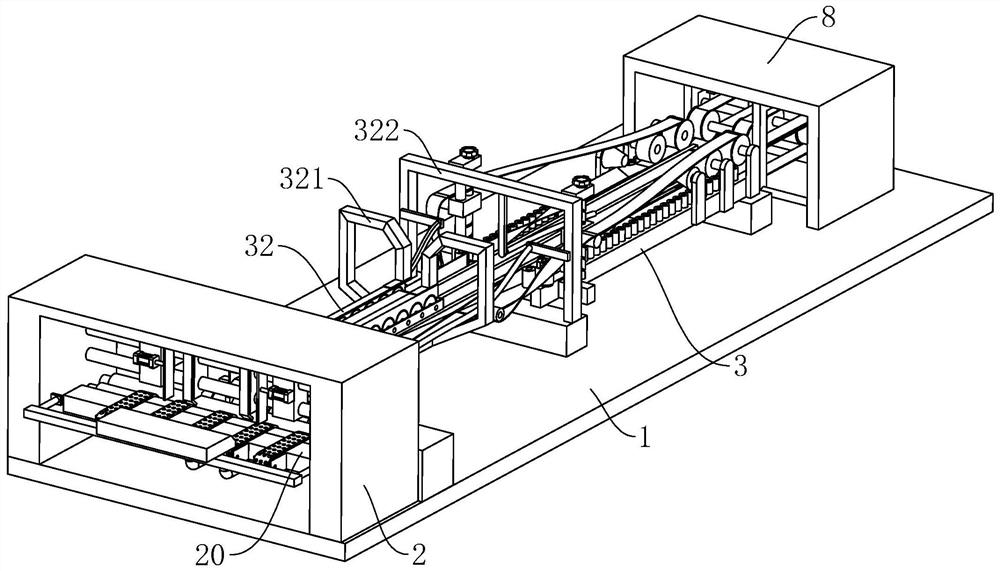

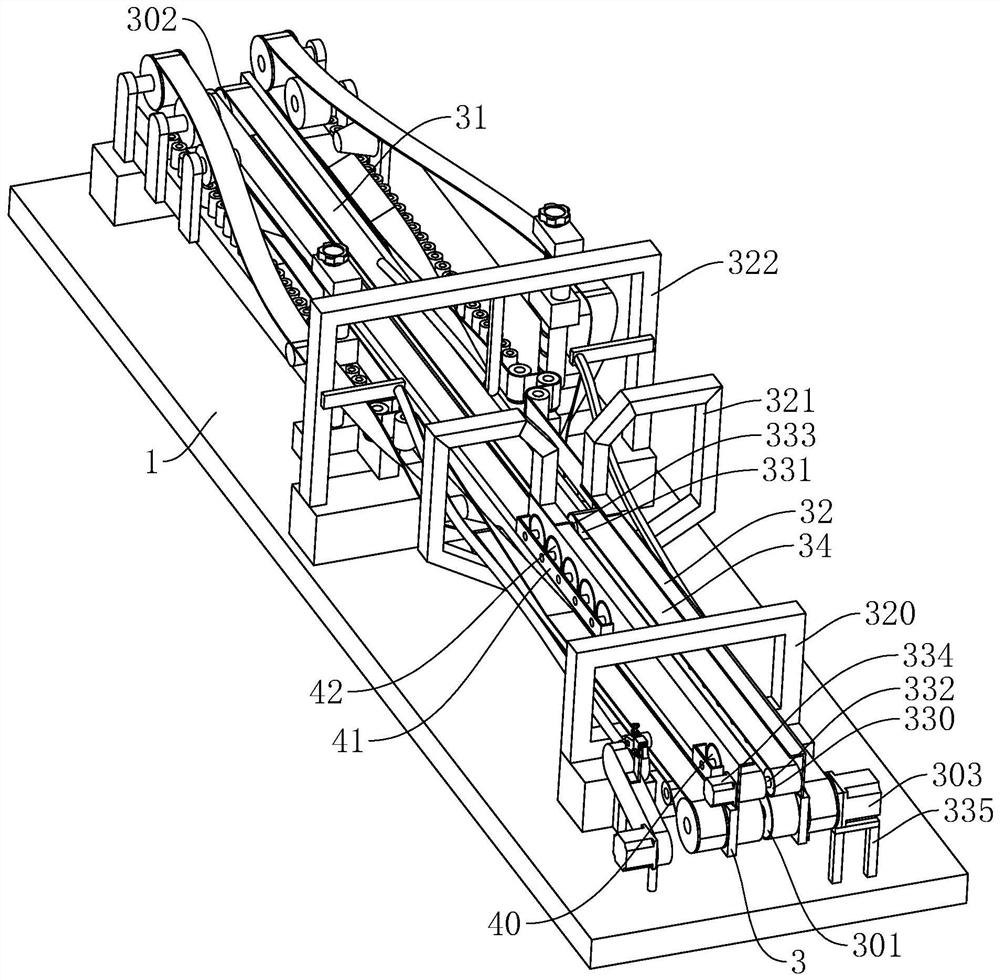

[0039] The following is attached Figure 1-7 The application is described in further detail.

[0040] The embodiment of the present application discloses an automatic gluing machine with high gluing quality. refer to figure 1 , the automatic gluing machine with high glue quality includes a frame 1, a feeding mechanism installed on the frame 1, a conveying mechanism and a blanking mechanism, and the feeding mechanism, the conveying mechanism and the blanking mechanism successively load and Conveying and blanking; the automatic gluing machine also includes a gluing mechanism, an indentation mechanism, an edge-receiving mechanism, and a retracting mechanism installed on the conveying mechanism. The cardboard on the mechanism is treated with glue, indentation, edge finishing and folding.

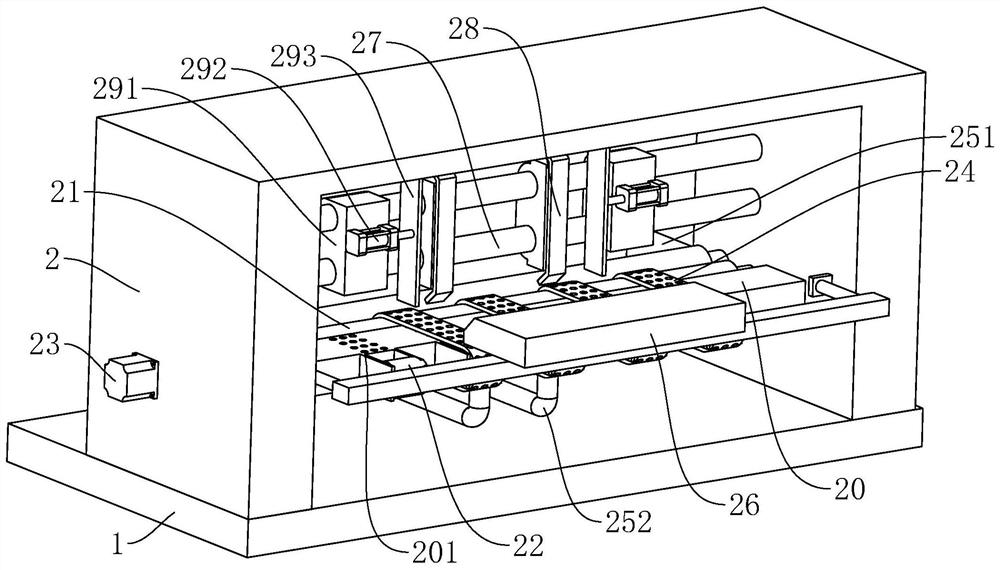

[0041] refer to figure 2 , the feeding mechanism includes a feeding rack 2, a feeding frame 20, an active feeding shaft 21, a driven feeding wheel 22 and a suction belt 24, and the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com