Pneumatic tire

A technology of pneumatic tires and tires, which is applied to the reinforcement layer of pneumatic tires, special tires, tire parts, etc., which can solve the problems of deterioration of handling stability and reduced torsional rigidity of bead parts, etc., to improve handling stability and improve The effect of ride comfort performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, one embodiment of the present invention will be described based on the drawings.

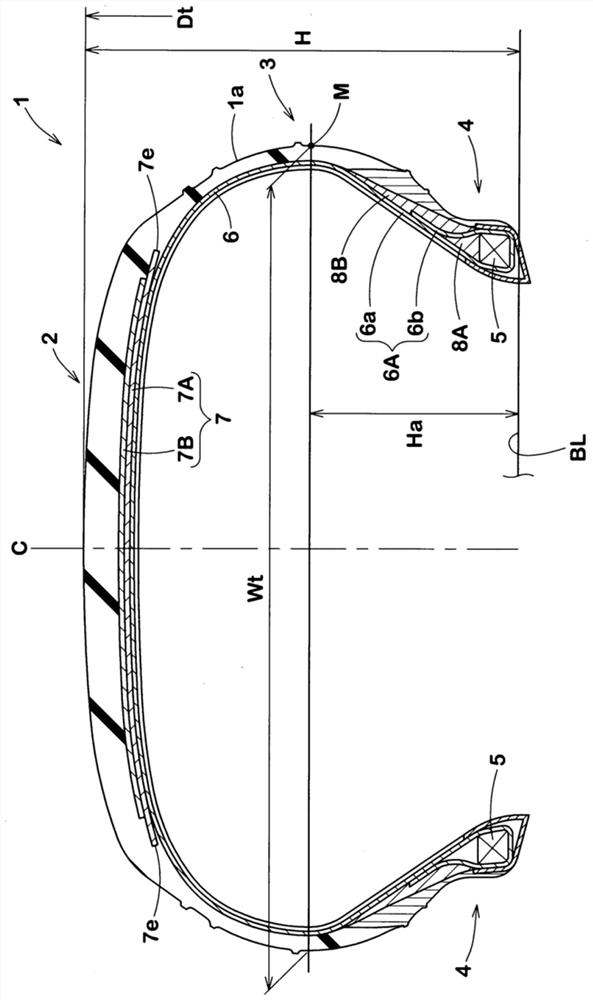

[0032] figure 1 It is a tire meridian cross-sectional view of a pneumatic tire (hereinafter, may be simply referred to as a "tire" in some cases) 1 according to this embodiment, including a tire rotation axis (not shown). figure 1 For example, a tire 1 for a passenger car is shown. However, the present invention can also be applied to tires 1 for heavy loads and the like.

[0033] In this specification, unless otherwise specified, the size of each part of the tire 1 is a value determined when the bead part is held in a state not assembled to the rim to match the rim width specified by the tire size.

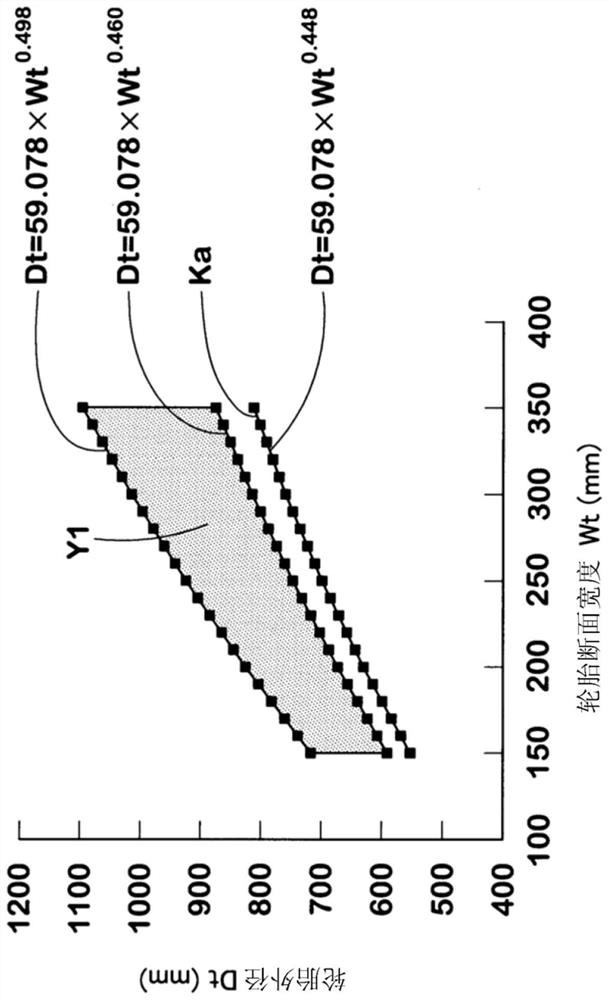

[0034] In the present embodiment, the tire 1 satisfies the following expressions (1) and (2) when Wt (unit: mm) is the tire cross-sectional width and Dt (unit: mm) is the tire outer diameter. Thus, in the present invention, the narrow-width large-diameter pneumatic tire 1 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Complex elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com