Two-stage vibration attenuation liquid-electric type active suspension with adjustable additional rigidity and damping and working method

A secondary vibration reduction, active suspension technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve the problems of constant damping stiffness, large inertial mass, large bushing spring, etc. Associated inertial forces, changing structural stiffness and damping, and downsizing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

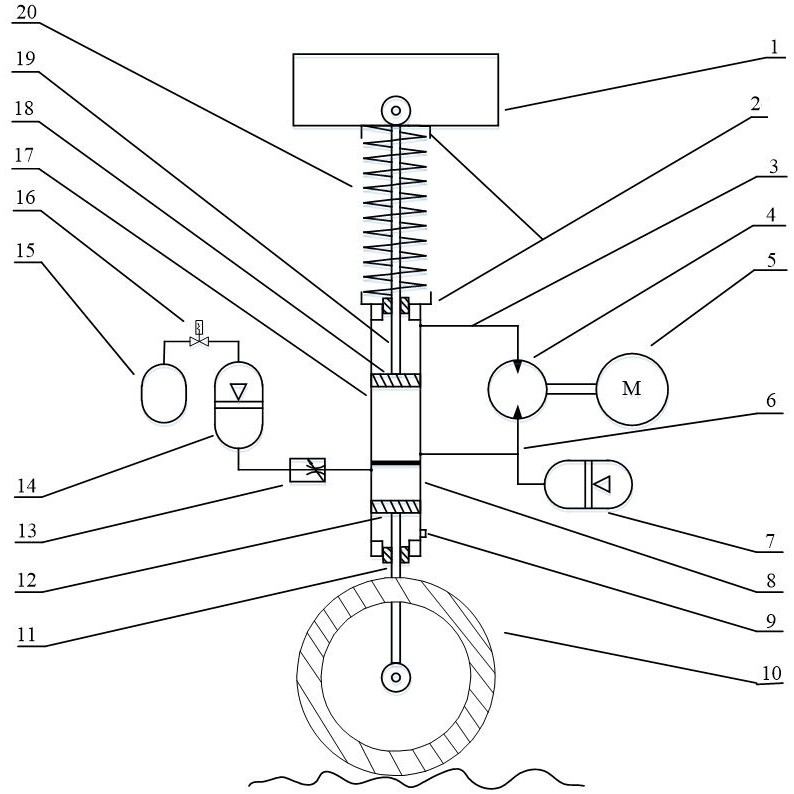

[0015] like figure 1 As shown, the orientation of the present invention is specified as follows: the wheel 10 is "below", and the vehicle body 1 is "above".

[0016] The secondary vibration-damping hydroelectric active suspension with adjustable additional stiffness and damping described in the present invention is installed between the wheel 10 and the vehicle body 1 above it, and is a primary vibration-damping structure composed of an active force actuator and a coil spring 20 and a secondary damping structure with adjustable damping stiffness, wherein the active force actuator includes an actuator hydraulic cylinder 17, a charge accumulator 7, a hydraulic pump / motor 4, and an electric / generator 5; the secondary vibration damping The structure includes a spring hydraulic cylinder 8 , an adjustable throttle valve 13 , a spring accumulator 14 , a solenoid valve 16 and an air storage tank 15 .

[0017] The actuator hydraulic cylinder 17 is vertically arranged, and a first pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com