Automatic pairing and intelligent welding equipment of baffle assembly for belt conveyor tensioning device

A technology of belt conveyor and tensioning device, which is applied in the direction of conveyor objects, transportation and packaging, etc., and can solve problems such as low work efficiency, large processing errors, and large welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0099] Example: see Figure 1 to Figure 16 .

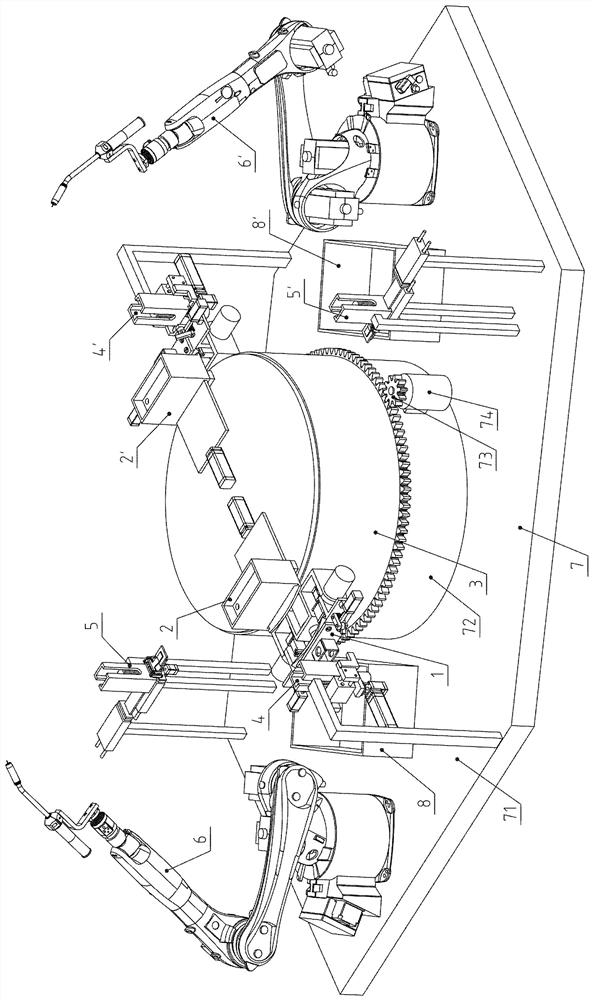

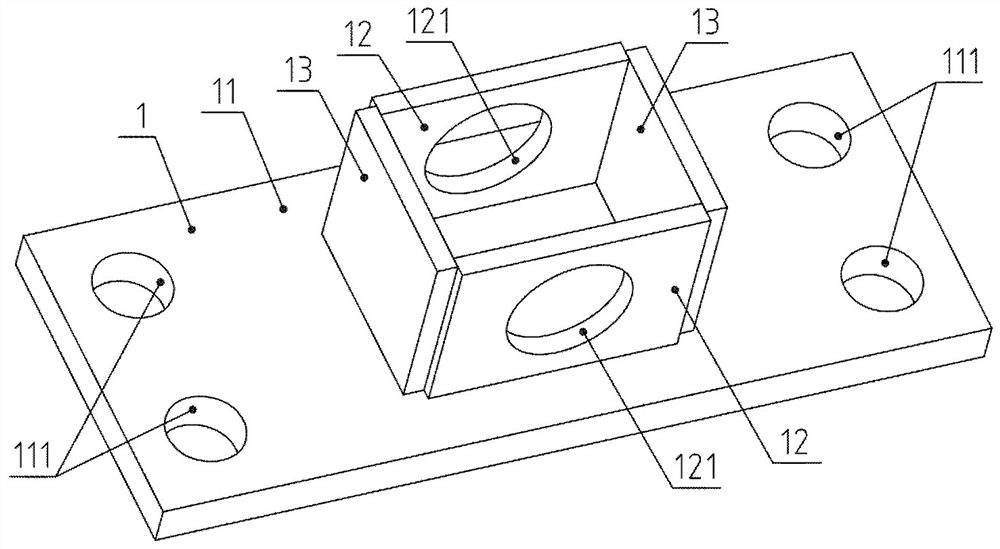

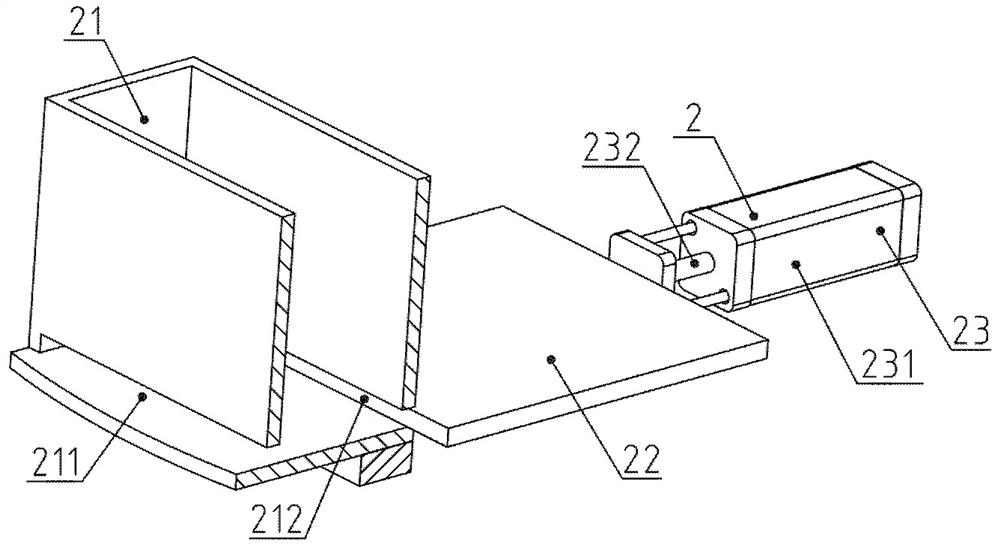

[0100] An intelligent welding equipment for automatic pairing of baffle assemblies for belt conveyor tensioning devices, including a bottom plate feeder 2, a rotating assembly 3, a side plate feeder 5, an intelligent welding robot 6, and a frame assembly 7;

[0101] Frame assembly 7 comprises frame 71, rotating support 72, rotating assembly driving gear 73 and rotating assembly servo motor 74; Coupling; the output shaft of the rotary assembly drive gear 73 and the rotary assembly servo motor 74 is fixedly connected;

[0102] The rotating assembly 3 includes a rotating sleeve 31 and a rotating sleeve gear ring 35, the rotating sleeve 31 and the rotating sleeve gear ring 35 are fixedly connected; the rotating sleeve 31 and the rotating support 72 are connected through a rotating pair; Mesh with the rotating assembly driving gear 73; the rotating assembly servo motor 74 drives the rotating assembly 3 to rotate through the combinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com