Sewing machine head machining process

A processing technology and sewing machine technology, applied in the processing technology field of sewing machine head, can solve the problems of low processing efficiency, neglected process, deviation of processing content, etc., so as to reduce the number of clamping, facilitate installation and operation, and reduce clamping effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now in conjunction with accompanying drawing, the present invention is further elaborated.

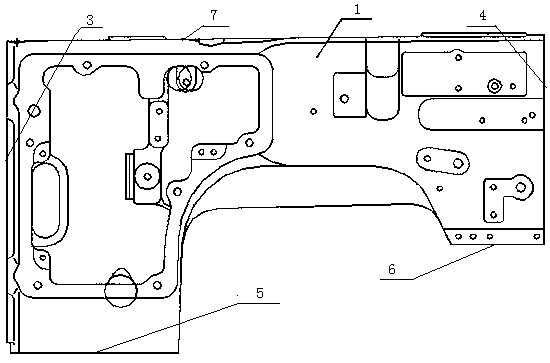

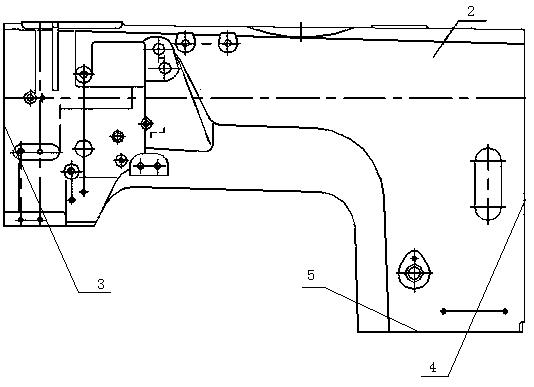

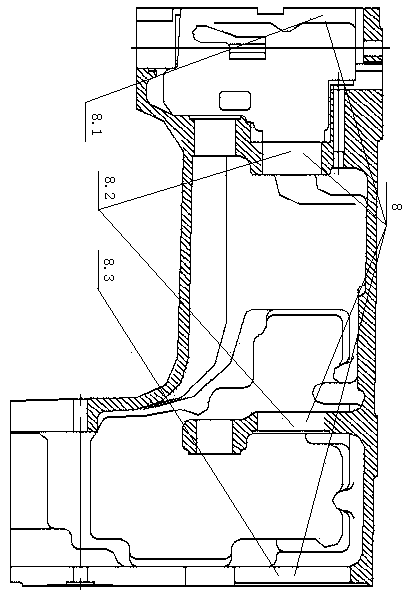

[0026] Such as Figure 1-8 As shown, a processing technology of a sewing machine head includes process one, process two and process three:

[0027] The first process is to place the sewing machine head to be processed on the fixture of the workbench of the vertical machining center, with three points on the A surface and two points on the top surface of the sewing machine head, and one point on the E surface in the direction of the spindle hole 8 of the machine head (that is, The front end face 3 or the rear end face 4 of the sewing machine head), the A face 2 is positioned at three points, and its distribution is that there are two points on the A face 2 near the rear end face 4, and on the A face 2 near the front end face There is a point at the 3 places, and the positioning point on the fixture corresponding to the 3 places on the A surface 2 near the front end has a balance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com