Wharf collecting and distributing system

A container and operating area technology, applied in the field of terminal collection and distribution systems, can solve problems such as heavy traffic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

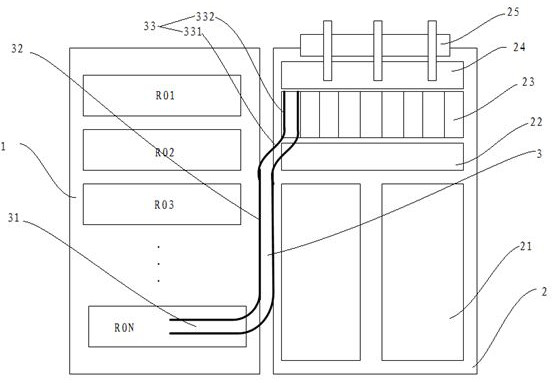

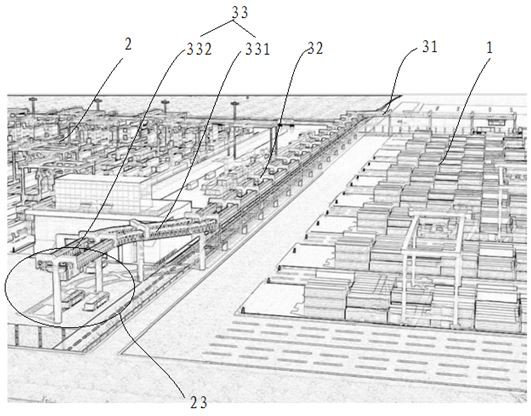

[0025] Such as figure 1 As shown, the wharf collection and distribution system proposed by the present invention includes the adjacent first collection and distribution area 1, the second collection and distribution area 2 and the collection and distribution empty track 3; wherein, the first collection and distribution area 1 includes A number of container areas R01, R02..., R0N arranged sequentially from the land side to the sea side; the second collection and distribution area 2 includes container yards 21, AGV operation areas 22, AGV buffer parking area 23, AGV and quay crane interaction area 24 and quay crane 25.

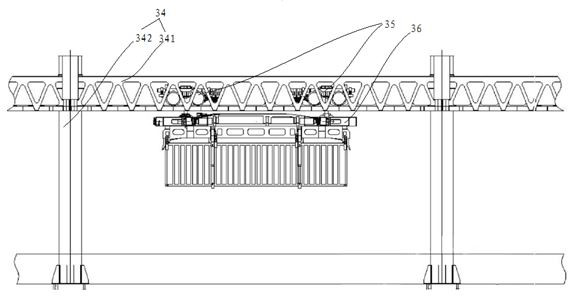

[0026] Such as figure 1 with figure 2 As shown, the collection and distribution empty track 3 includes a first curved section 31, a main section 32 and a second curved section 33 connected in sequence;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com