Environment-friendly rough filtration equipment for tap water treatment

A tap water and rough filtration technology, applied in water/sewage treatment equipment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of slow sedimentation, power consumption, and fast water flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

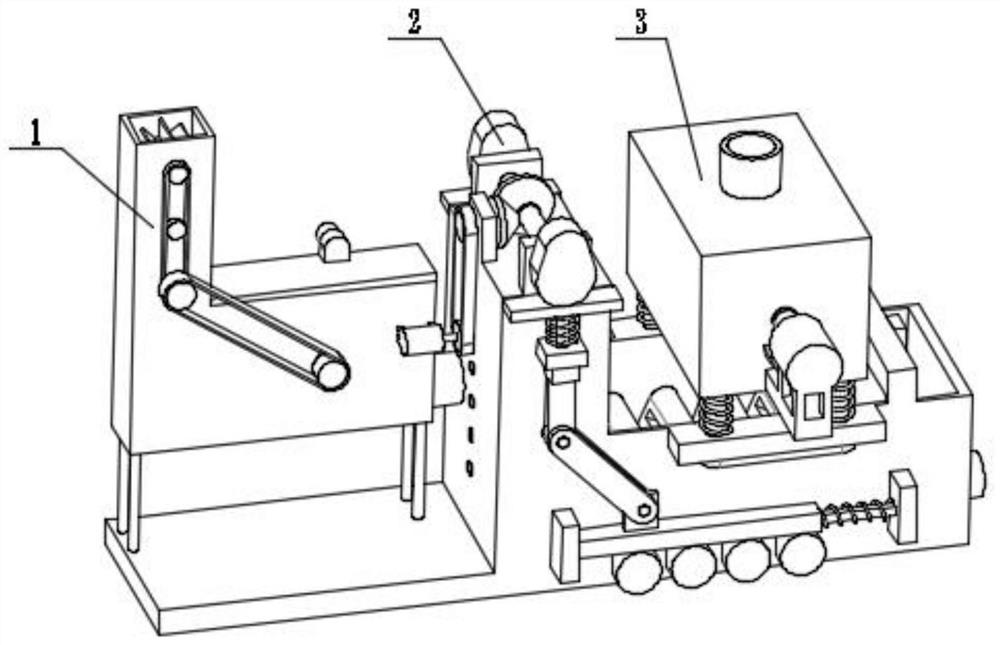

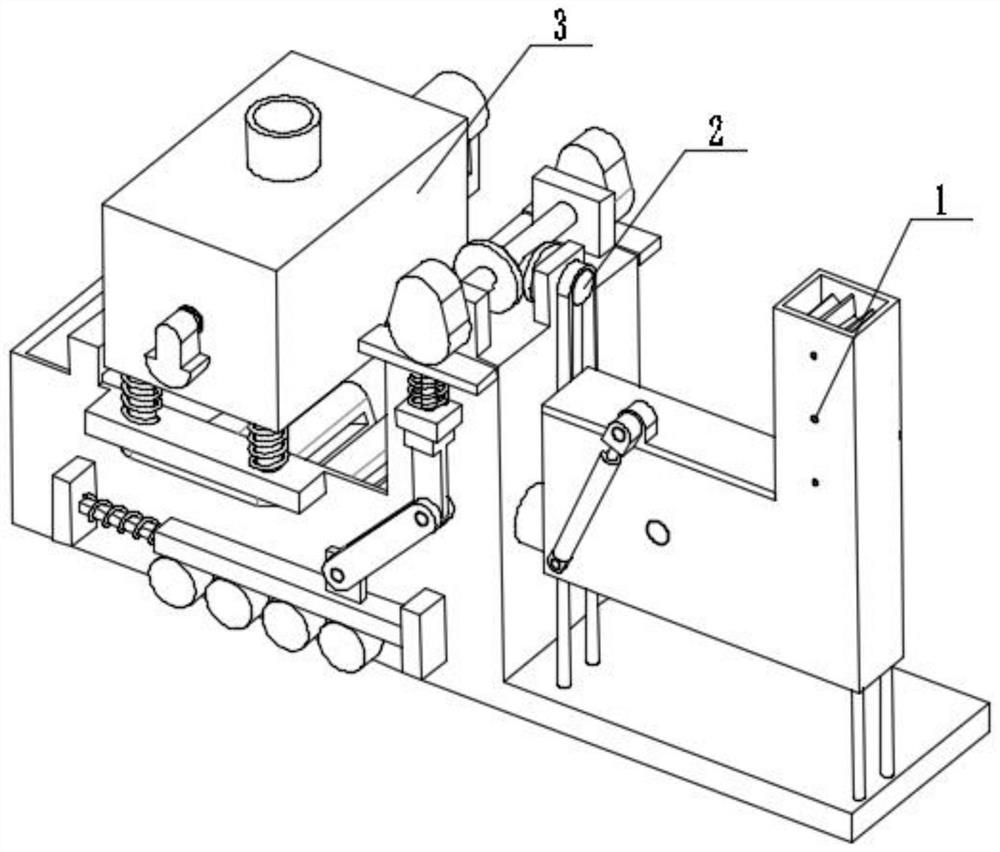

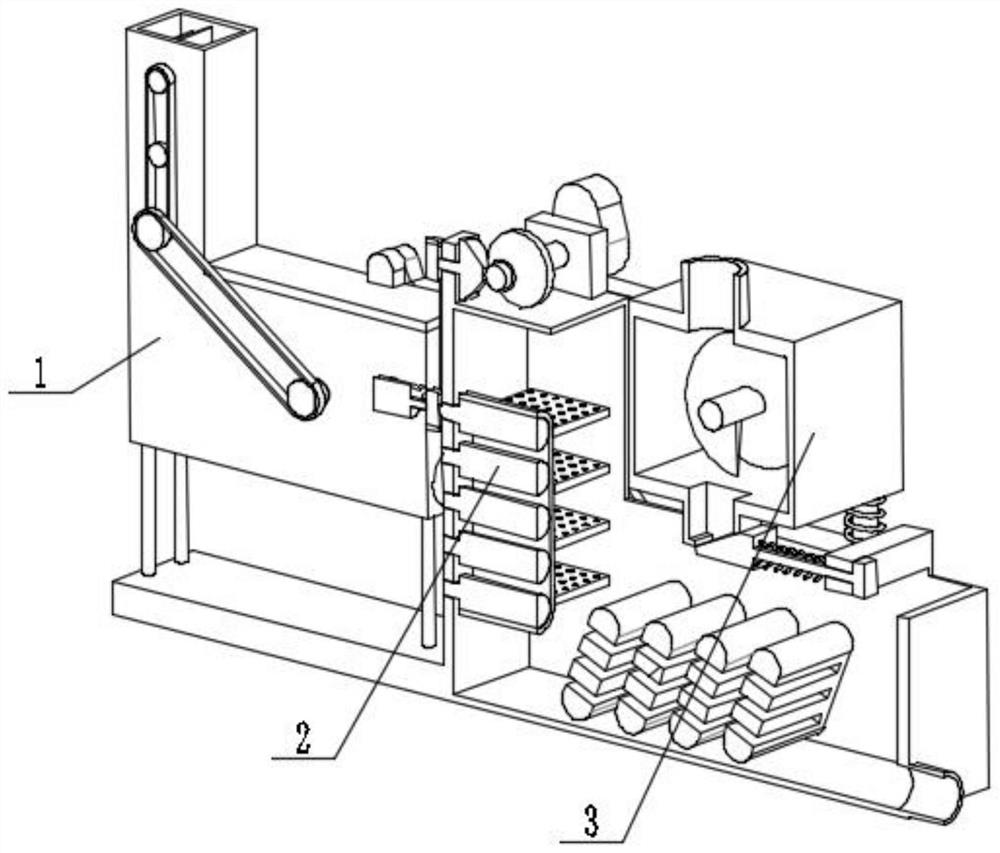

[0028] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 Describe this embodiment. The present invention relates to a coarse filtration device, more specifically, an environmentally friendly primary filtration device for tap water treatment, including a fuselage mechanism 1, a linkage mechanism 2, and a medicine box mechanism 3. The equipment can use the power of incoming water To achieve coarse filtration, the equipment can be used for secondary filtration, the equipment can effectively reduce the water speed, and the equipment can spray sedimentation agents.

[0029] The fuselage mechanism 1 is connected with the linkage mechanism 2 , and the fuselage mechanism 1 is connected with the medicine box mechanism 3 .

specific Embodiment approach 2

[0031] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13Describe this embodiment, this embodiment will further explain Embodiment 1, the described fuselage mechanism 1 includes a base 1-1, a coarse filter inlet tank 1-2, a pulley 1-3, a belt 1-4, a belt shaft Pulley 1-5, shaft pulley I1-6, belt I1-7, impeller 1-8, inspection door 1-9, hole seat 1-10, settling water tank 1-11, vibration slide hole 1-12, wedge 1-13, stepped square column 1-14, spring 1-15, water outlet 1-16, connecting seat 1-17, limit square column 1-18, return spring 1-19, hinged joint 1-20, hydraulic cylinder 1-21, outer leakage opening 1-22, belt shaft rotating wheel 1-23, T-shaped slot 1-24, T-shaped filter plate with holes 1-25, filter hole 1-26, limit rod 1-27, reset Spring I1-28, base 1-1 is connected with coarse filter inlet tank 1-2, pulley 1-3 is frictionally connected wi...

specific Embodiment approach 3

[0033] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 Describe this embodiment, this embodiment will further explain the first embodiment, the linkage mechanism 2 includes a bevel gear 2-1, a connecting shaft 2-2, a cam 2-3, a matching seat 2-4, and a connecting column 2-5 , spring 2-6, belt shaft pulley A2-7, bevel gear I2-8, motor 2-9, head roller pulley 2-10, transmission belt A2-11, driving roller 2-12, passive roller 2 -13, belt with filter plate 2-14, gear A2-15, rack with square hole 2-16, rocking grid plate with shaft 2-17, hinged arm 2-18, hinged connection seat 2-19, bevel gear 2-1 is connected with the connecting shaft 2-2, the connecting shaft 2-2 is rotationally connected with the settling water tank 1-11, the connecting shaft 2-2 is connected with the cam 2-3, and the cam 2-3 is in contact with the mating seat 2-4, The matching se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com