A kind of composite nanocatalyst of mxene and transition metal sulfide based on fiber skeleton and preparation method thereof

A nano-catalyst and transition metal technology, which is applied in the fields of energy and catalysis and nano-materials, can solve the problems of reducing the loading area of molybdenum disulfide nano-sheets, affecting the electrocatalytic performance, and easy stacking of MXene sheets, which is beneficial to electrochemical catalysis. , Increase the effective load surface area, the effect of green process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

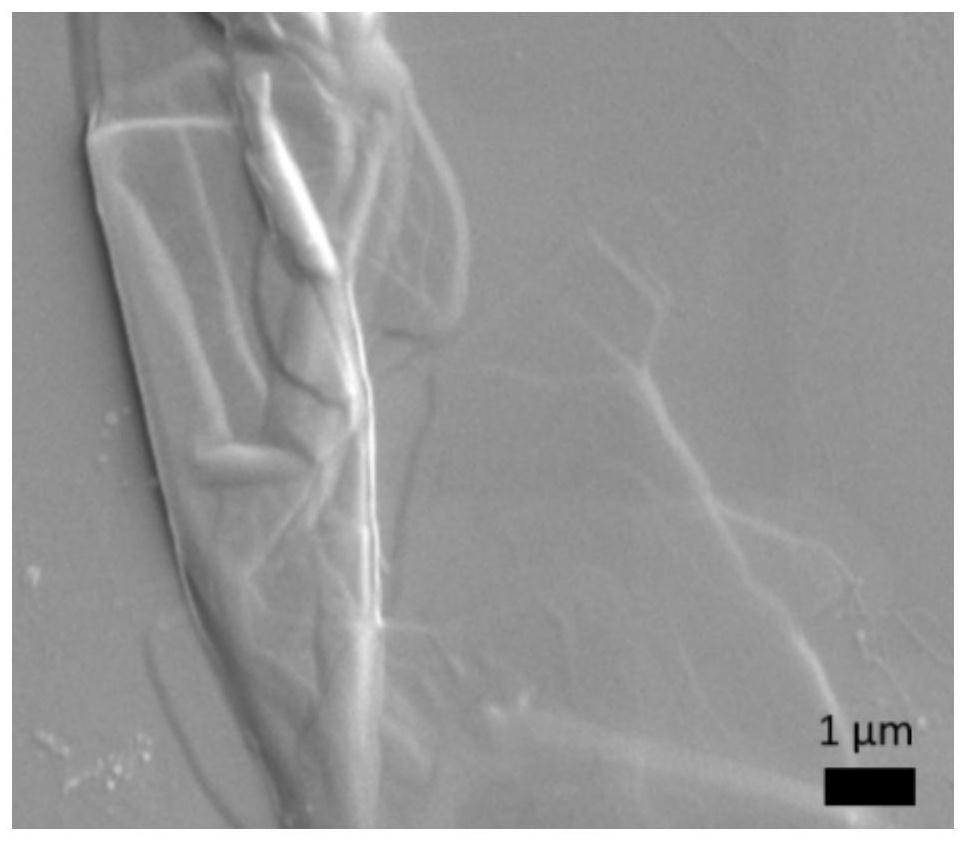

[0047] A kind of preparation method of MXene based on fiber skeleton and transition metal sulfide composite nano-catalyst, comprises the steps:

[0048] (1) Weigh 1g polyacrylonitrile (PAN, molecular weight is 10 4 ) was dissolved in 20g of N,N-dimethylformamide (DMF), and after being completely dissolved, 5mL was placed in a syringe, electrospun at a voltage of 28kv, and the spun fiber membrane was removed after 5h;

[0049] (2) Weigh 0.6g titanium carbide powder (etched and dried Ti 3 C 2 ) into 30mL of deionized water, ultrasonically dissolved to uniformly obtain a titanium carbide dispersion, then add 0.06g of ammonium tetrathiomolybdate for dissolution, and at room temperature, immerse the spinning fiber membrane described in step (1) in the solution under a nitrogen atmosphere Take out and dry after 1h to obtain impregnated membrane;

[0050] (3) Under the protection of argon, place the impregnated film of step (2) in a high-temperature furnace, place 0.06g of sulfur ...

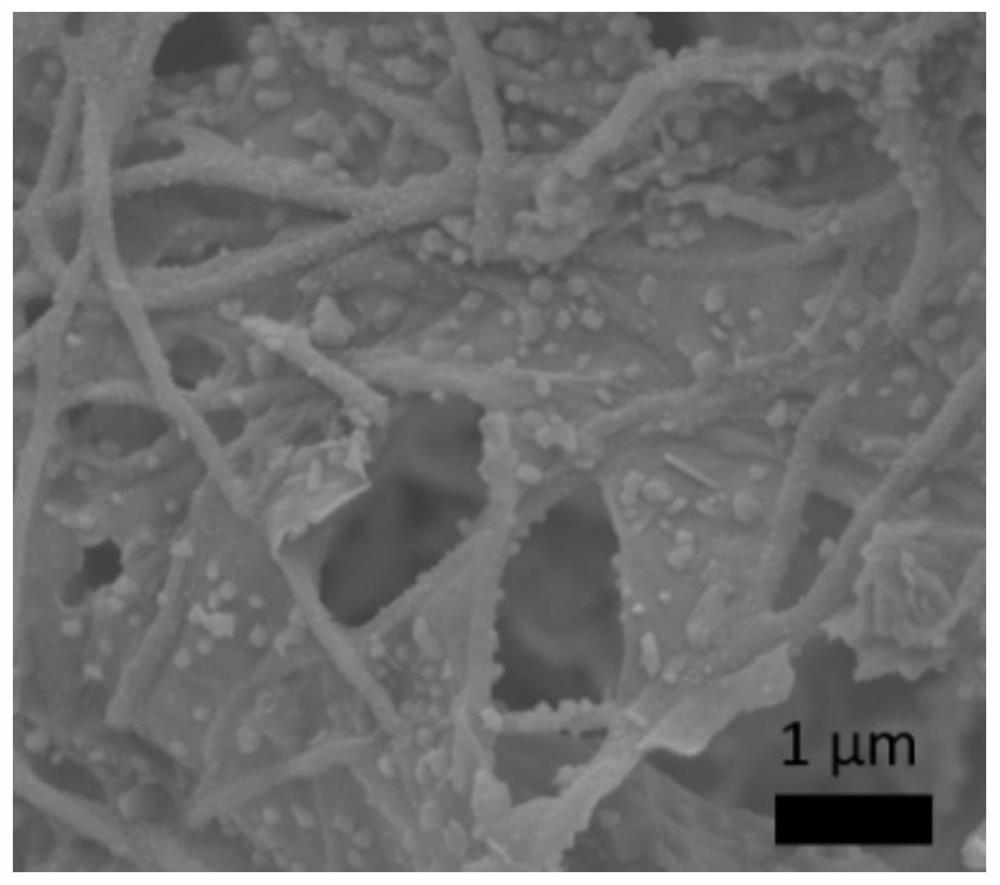

Embodiment 2

[0052] A kind of preparation method of MXene based on fiber skeleton and transition metal sulfide composite nano-catalyst, comprises the steps:

[0053] (1) take by weighing 5g polyacrylonitrile (PAN, molecular weight is 10 4 ) was dissolved in 20g of N,N-dimethylformamide (DMF). After complete dissolution, 5mL was placed in a syringe, electrospun at a voltage of 28kv, and the spun fiber membrane was removed after 5h.

[0054] (2) Weigh 0.45g titanium carbide powder (Ti 3 C 2 ) was added into 30mL deionized water, ultrasonically dissolved to obtain a titanium carbide dispersion, and then 0.064g ammonium molybdate was added to dissolve, at room temperature, the spinning fiber membrane described in step (1) was immersed in the solution for 5h under a nitrogen atmosphere and then taken out Dried to obtain impregnated membrane;

[0055] (3) Under the protection of argon, place the impregnated film of step (2) in a high-temperature furnace, place 0.128g of sulfur powder upstream...

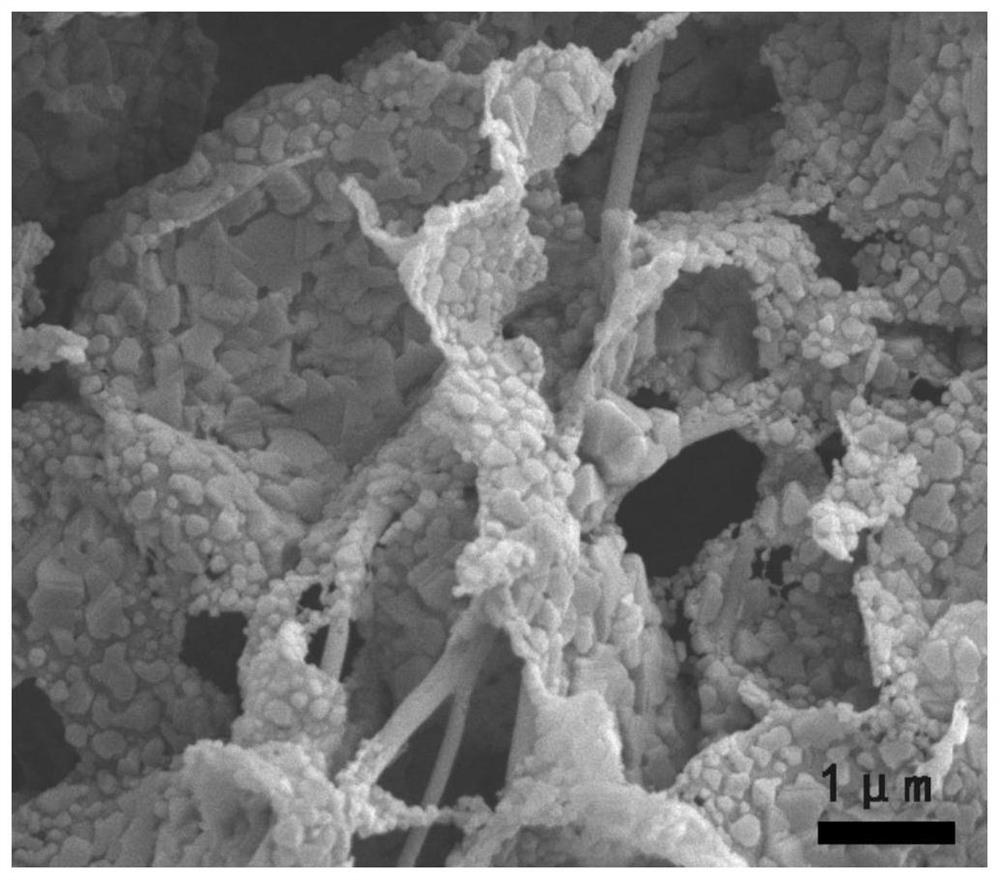

Embodiment 3

[0057] A kind of preparation method of MXene based on fiber skeleton and transition metal sulfide composite nano-catalyst, comprises the steps:

[0058] (1) Weigh 3.53g polyacrylonitrile (PAN, molecular weight is 10 4 ) was dissolved in 20g of N,N-dimethylformamide (DMF). After complete dissolution, 5mL was placed in a syringe, electrospun at a voltage of 28kv, and the spun fiber membrane was removed after 5h.

[0059] (2) Weigh 0.3g two-dimensional titanium carbide powder (Ti 3 C 2 ) into 30mL of deionized water, ultrasonically dissolved to uniformly obtain a titanium carbide dispersion, then add 0.075g of cobalt chloride to dissolve, and at room temperature, immerse the spinning fiber membrane described in step (1) in the solution for 3 hours under an argon atmosphere Take out and dry to obtain impregnated membrane;

[0060] (3) Under the protection of argon, place the impregnated film of step (2) in a high-temperature furnace, place 0.225g of sulfur powder upstream, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com