Exhaust oil separation structure, compressor and air conditioner

A compressor and oil separation technology, which is applied to machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of reduced space utilization, large space occupation, and increased compressor size, so as to reduce volume and improve oil and gas separation. The effect of efficiency and separation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

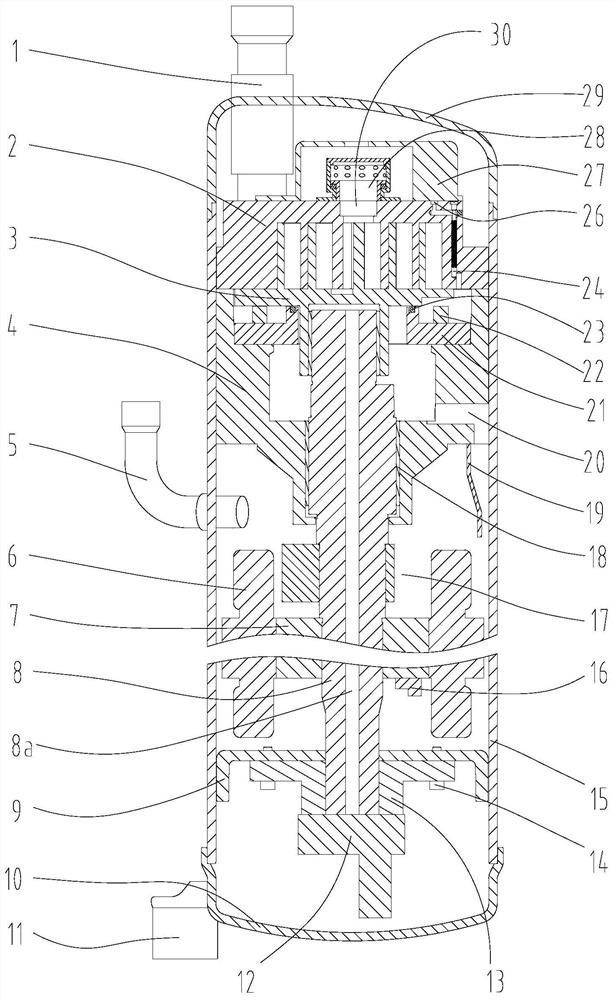

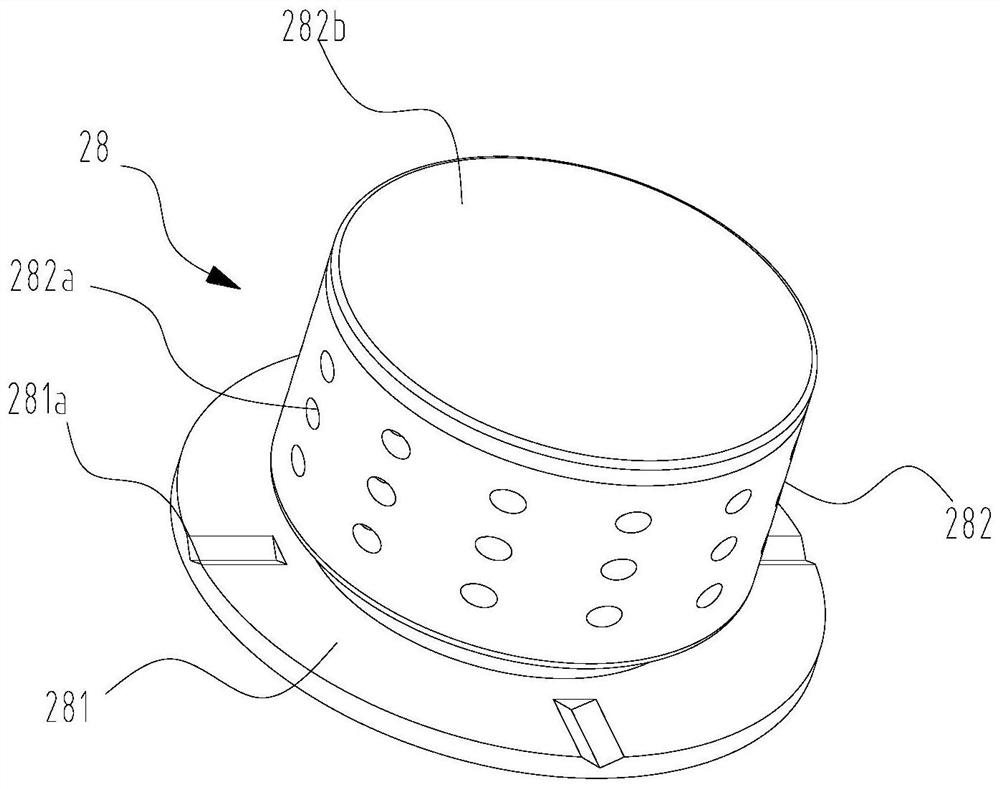

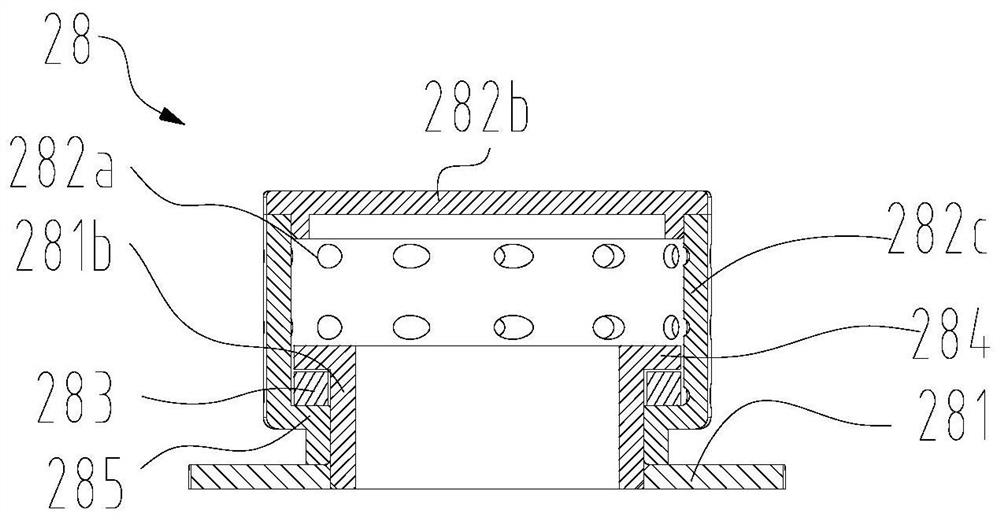

[0045]see in conjunction Figure 1 to Figure 12 As shown, according to the embodiment of the present application, the exhaust oil separation structure includes a base 281 and an oil separation cylinder 282. The oil separation cylinder 282 is rotatably mounted on the base 281 and can form an axial limit relative to the base 281. The oil separation cylinder 282 The top is sealed, and a through hole 282a is opened on the side wall of the oil separator cylinder 282. An acute angle θ is formed between the extension direction of the through hole 282a and the first plane. The first plane is the center of the outer opening of the through hole 282a and the oil separator cylinder at the same time. The vertical plane of the central axis of 282.

[0046] The exhaust oil separation structure of the present application is arranged at the exhaust port of the pump body structure inside the compressor, and the oil separation cylinder 282 of the exhaust oil separation structure can be lifted by...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap