Laser with calibration mechanism corresponding to axial degree of discharge tube

A calibration mechanism and corresponding technology, applied in the field of lasers, can solve problems such as poor practicability, achieve the effect of solving the poor efficiency of axial calibration, improving work efficiency, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

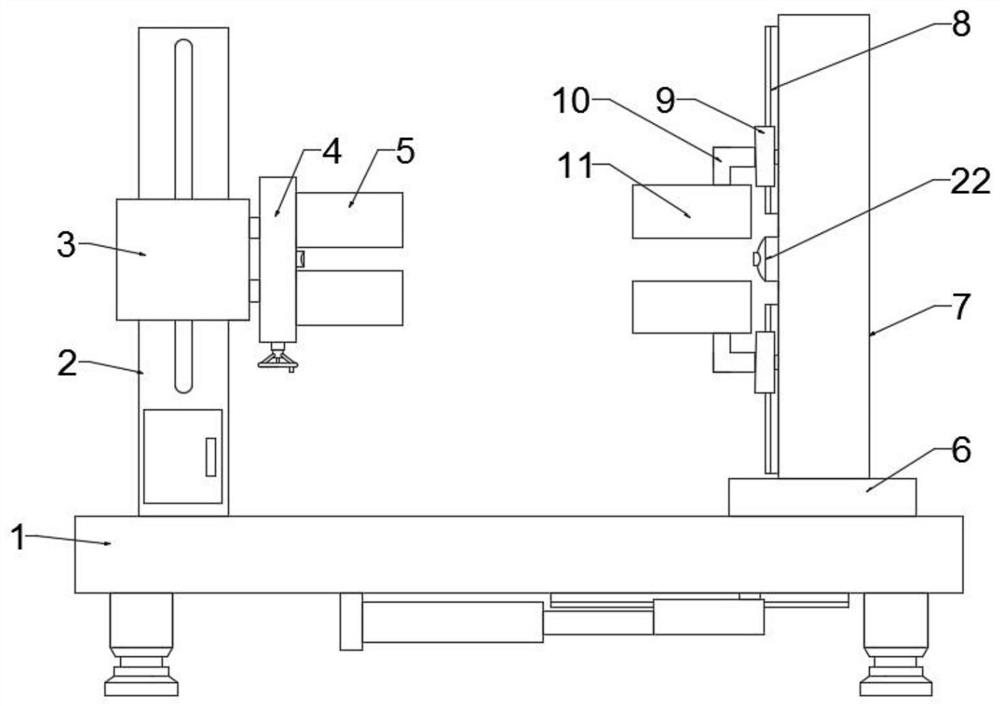

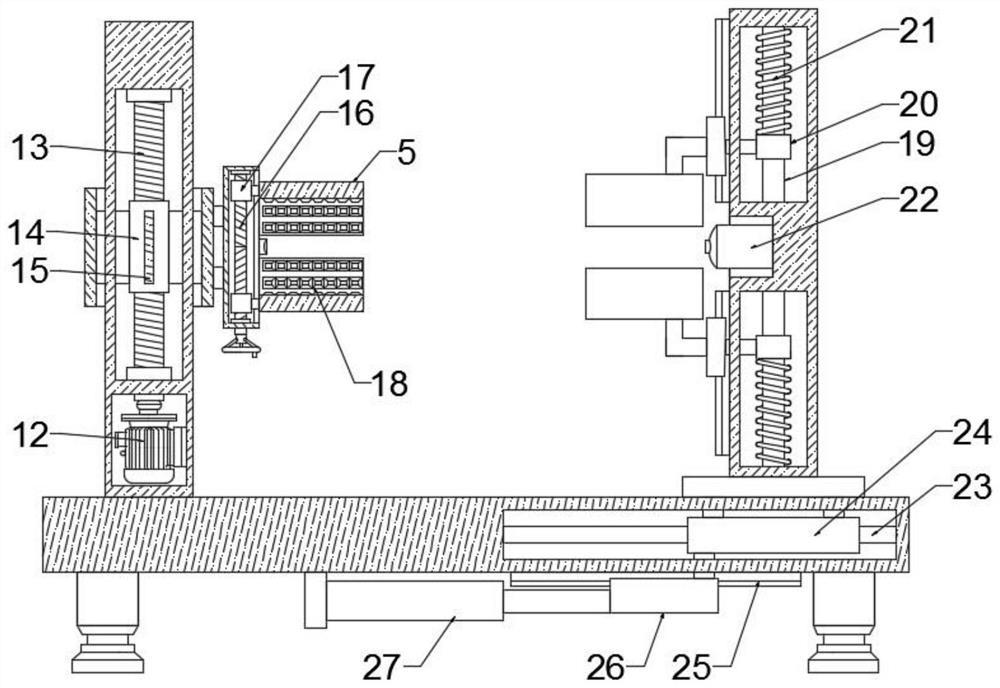

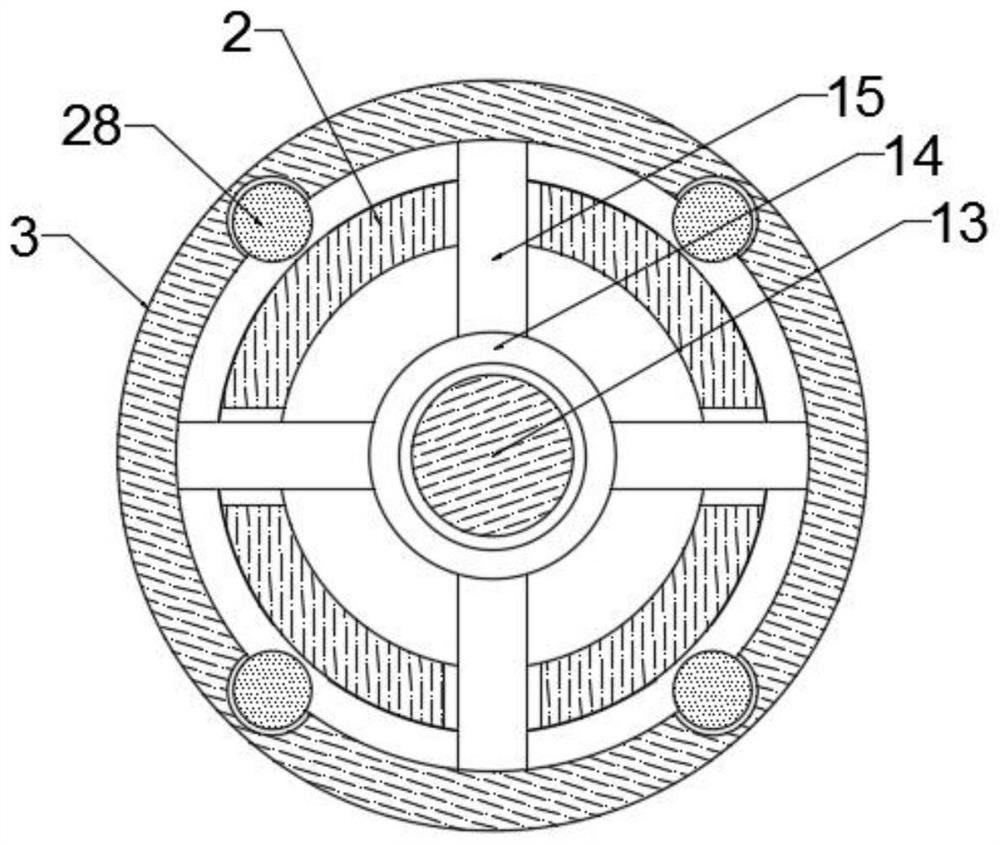

[0022] Embodiment 1: see Figure 1-4 , a laser with a calibration mechanism corresponding to the axis of the discharge tube in the present invention includes a base plate 1, which is a horizontally arranged rectangular plate, and one side of the top surface of the base plate 1 is vertically fixed with a cylindrical Guide column 2; the cylinder upper movable cover of guide column 2 is provided with stabilizing sleeve 3, and the tube body side of stabilizing sleeve 3 is vertically fixedly connected with disc 4, and the upper and lower ends of the inner surface of disc 4 are horizontally movable respectively. There is a movable splint 5 with an inner curved surface opposite to it; the other side of the top surface of the bottom plate 1 is horizontally provided with a rectangular sliding plate 6, and the middle part of the top surface of the sliding plate 6 is vertically fixed with a rectangular support column 7; the support column 7 The upper and lower parts of the inner surface ...

Embodiment 2

[0027] Embodiment 2: When the present invention is used, firstly, the motor 12 and the electric push cylinder 27 are electrically connected to the external power supply through wires respectively; It is convenient to place the laser of the discharge tube to be calibrated horizontally between the two fixed splints 11. Under the elastic action of the thrust spring 21, it is convenient to push the sleeve 20 to drive the sliding block 9 at the outer end of the connecting rod to slide on the T-shaped guide rail 8. Through the relative sliding of the sliding block 9, it is convenient to drive the fixed splint 11 at the bent end of the L-shaped curved rod 10 to clamp and fix the laser; the operator then places the discharge tube between the movable splints 5, and drives the rotating shaft by rotating the adjustment hand wheel 16 is rotated, the positive and negative threads on the surface of the rotating shaft 16 facilitate the relative movement of the two threaded pipes 17, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com