Time-staggered fixed-point heating desoldering device and method for circuit board components

A technology for components and circuit boards, which is applied to the field of fixed-point heating and desoldering devices for circuit board components at the wrong time, can solve the problems of low disassembly efficiency, high energy consumption, large inertia, etc., so as to improve heating fineness and heating efficiency, improve Reuse rate, achieve the effect of non-destructive disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0048] The present application will be further described below with reference to the accompanying drawings. The following examples are for more clearly illustrative of the technical solutions of the present invention without limiting the scope of the present application.

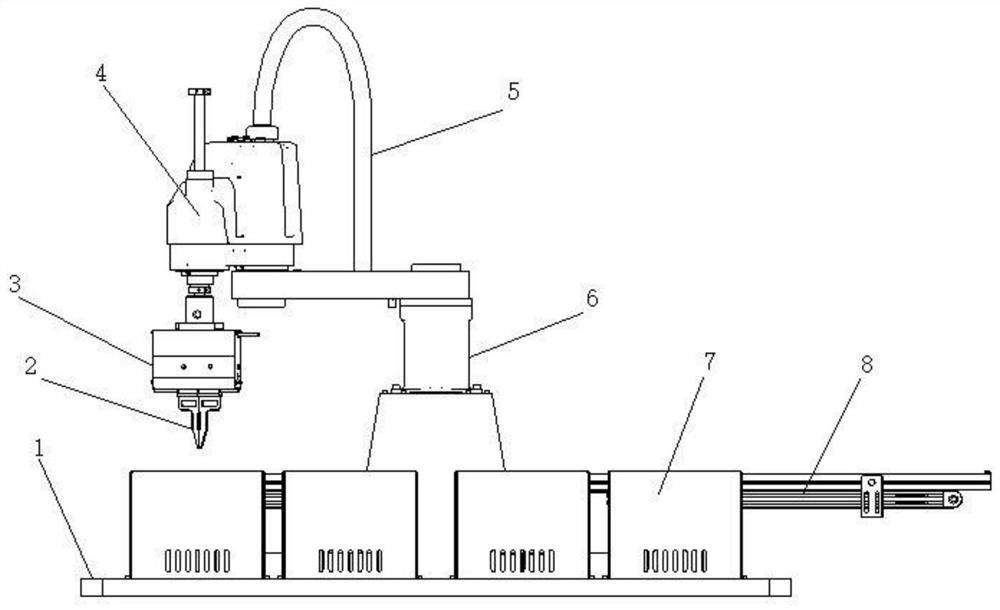

[0049] Such as figure 1 As shown, a circuit board component is indicated by a circuit board component of the present invention, which includes a control system, a station table, a component jaw 2, a clamping control block 3 carrying a CCD camera, a four-axis robot 4, heating Decamination module 7, component conveying mechanism 8, robotic column 6 and line protective sleeve 5 and associated gas paths, circuits;

[0050] The heating unpaid module 7, the component conveying mechanism 8, and the robotic column 6 are fixed to the station surface 1;

[0051] The component jaw 2 is fixed to the four-axis robot 4, and the four-axis robot 4 is disposed on the robotic column 6;

[0052] The control system scheduling compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com