Quick-plug connector with novel combined structure

A combined structure and plug-in joint technology, which is applied in the direction of pipes/pipe joints/fittings, elbows, hose connection devices, etc., can solve the problem that the intubation end and the threaded end cannot rotate freely.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

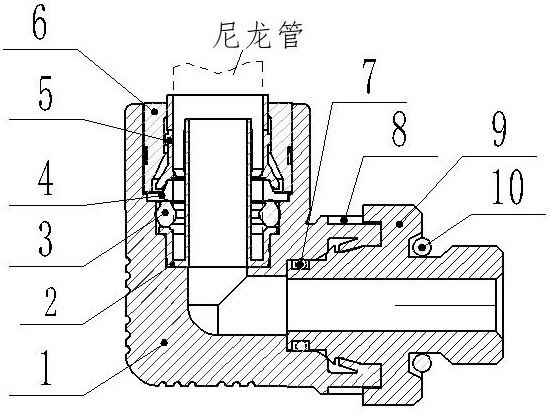

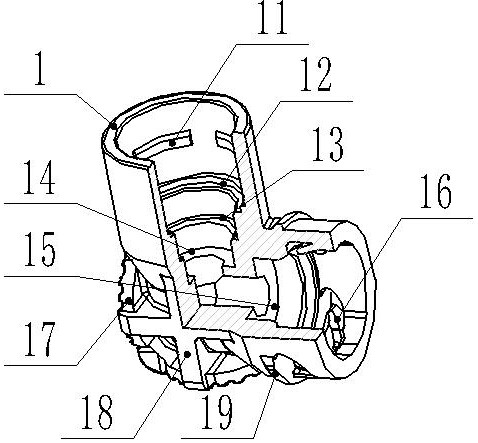

[0023] as attached figure 1 to attach Image 6 Shown:

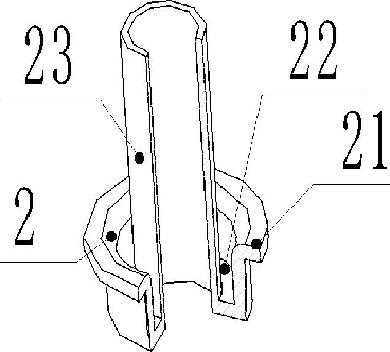

[0024] The invention provides a quick-plug connector with a new combination structure, which includes a body (1), and four hanging platforms (11) are sequentially arranged inside the body (1), and a compression sleeve (6) is pressed into the body (1) from the head. ), the hanging platform (11) fits into the annular groove (61) to complete the compression connection, and the first step hole (12), the second step hole (13), and the third step hole (14) are in sequence Below (11), there are fixed rings (4), Y-shaped sealing rings (3), and guide rods (2), respectively. The fixed rings (4) are pressed and fixed by the compression sleeve (6) after being pressed, The snap ring (5) is freely installed on the fixed ring (4), and its inner cone surface (55) is in contact with the upper cone surface (42) of the fixed ring. When working, its outer cone surface (57) is in contact with the inner cone surface of the compression sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com