Patents

Literature

38results about How to "Guaranteed free spins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

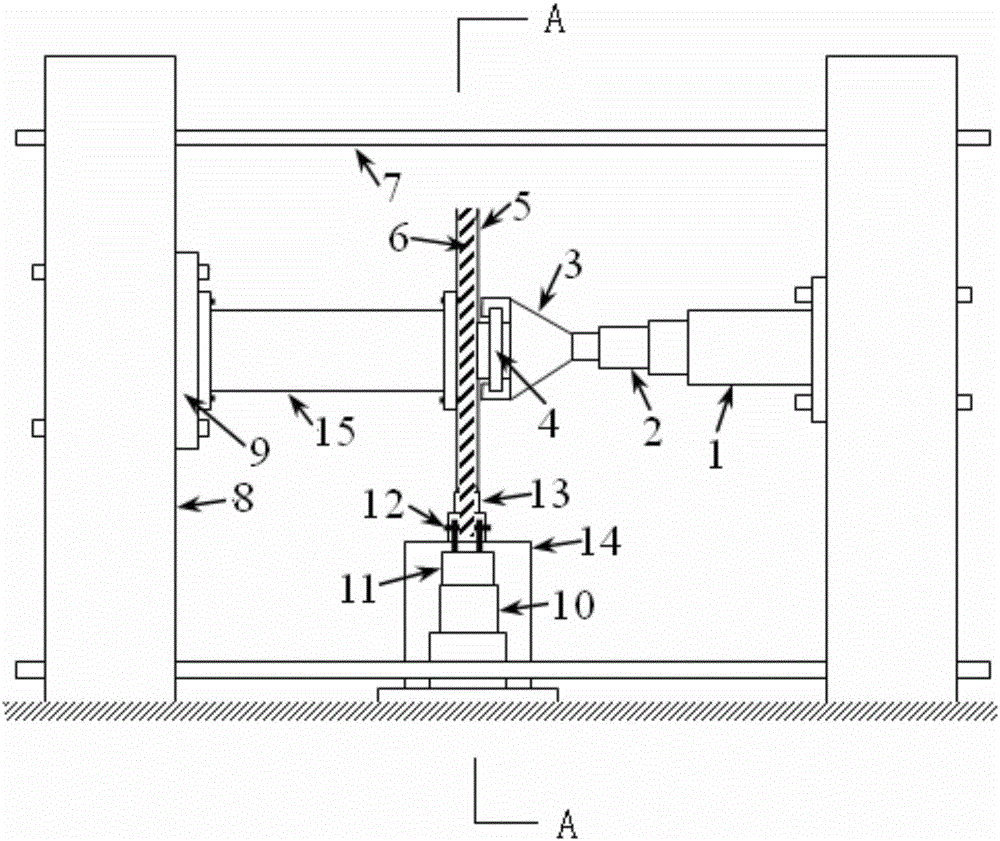

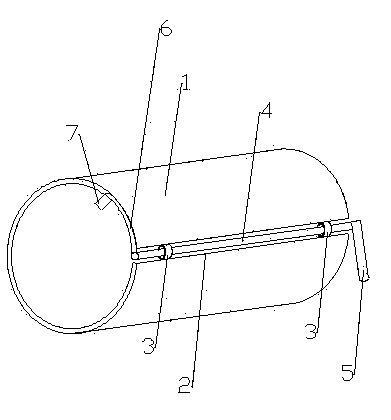

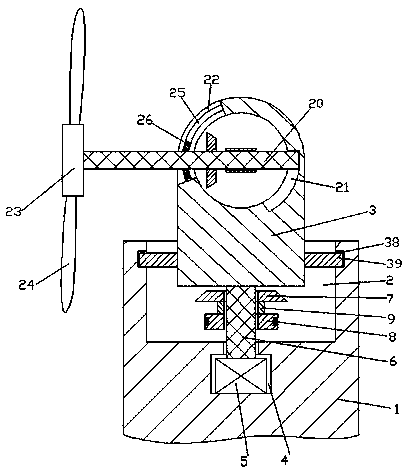

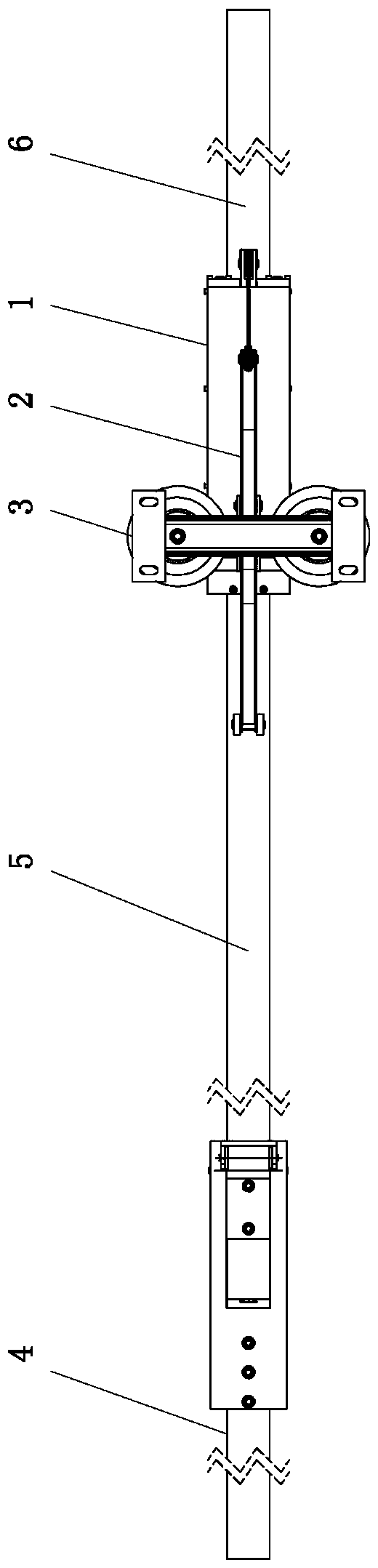

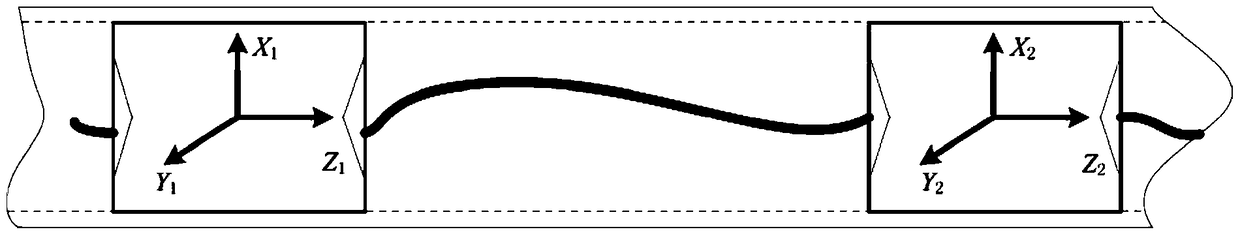

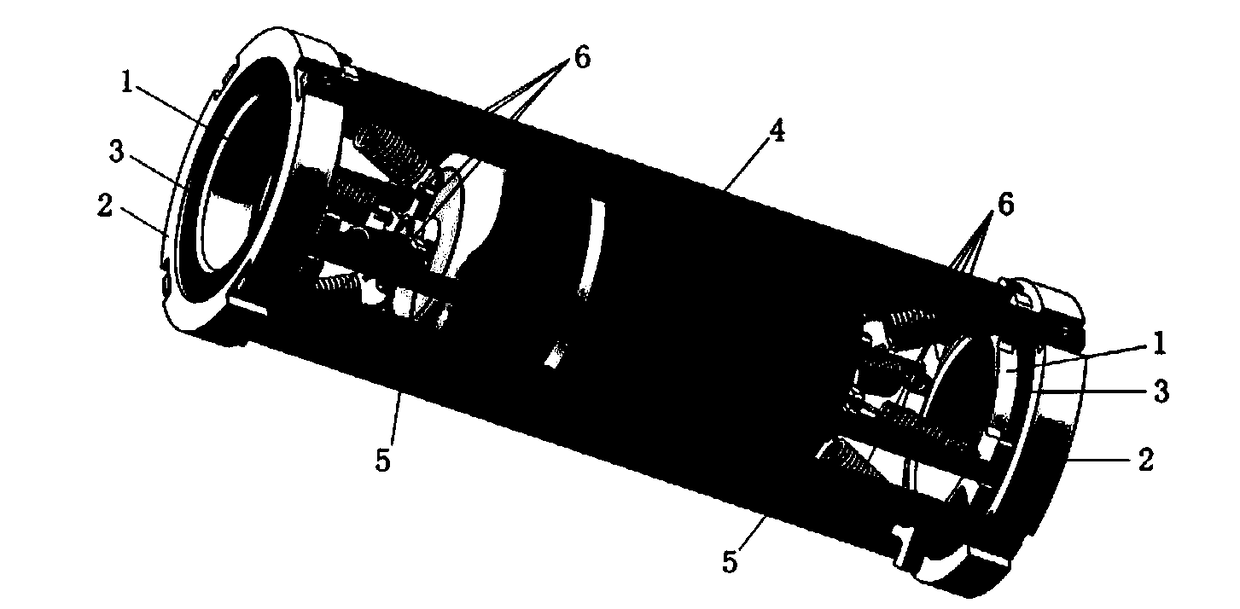

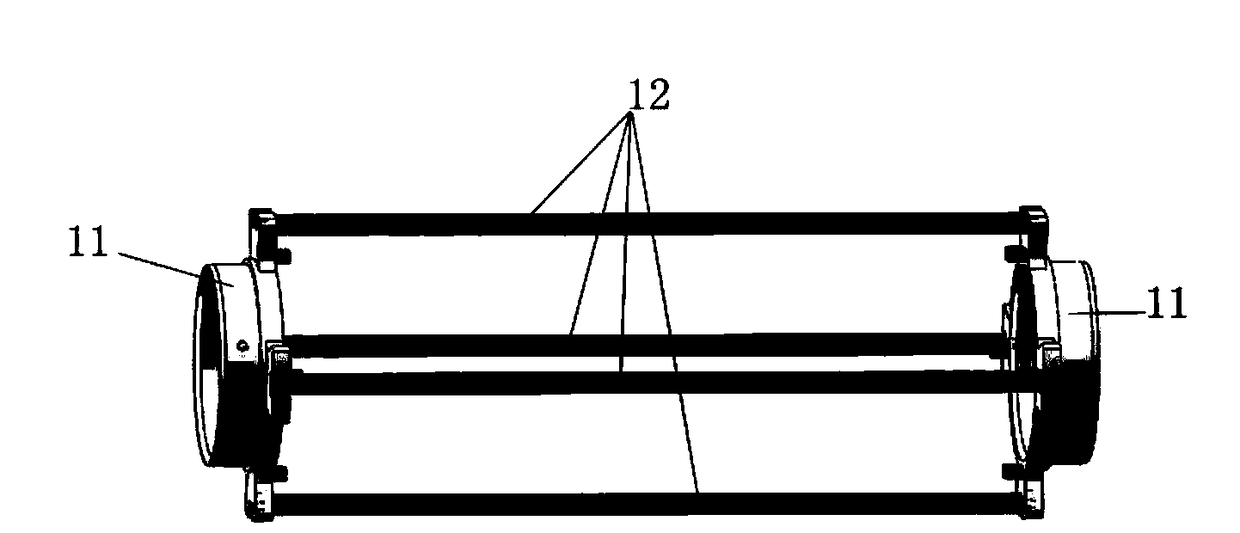

Fiber optic vector hydrophone with posture self-correcting function

ActiveCN105387924AEnsure consistencyReduce side pressureSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFiberHydrophone

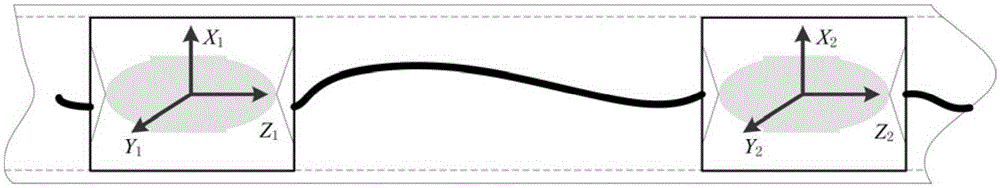

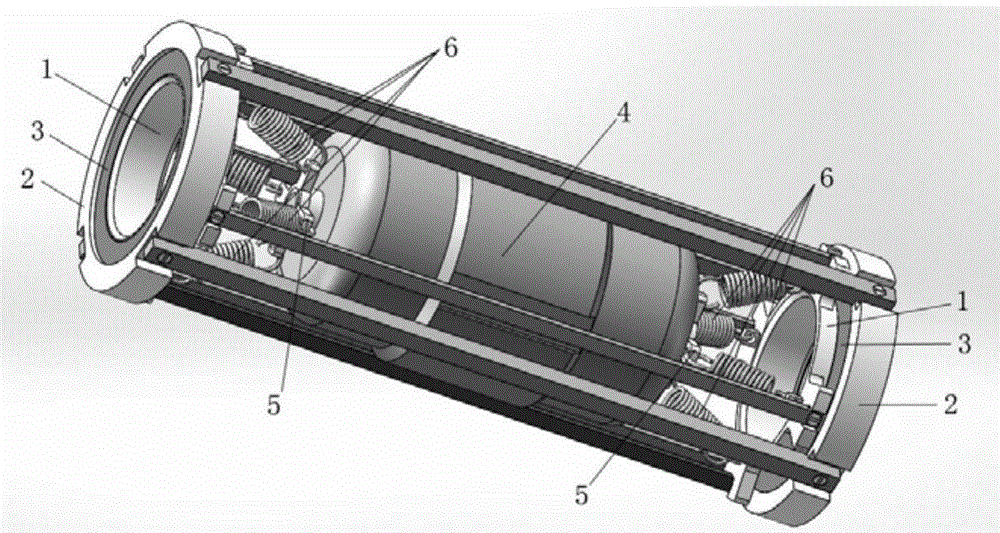

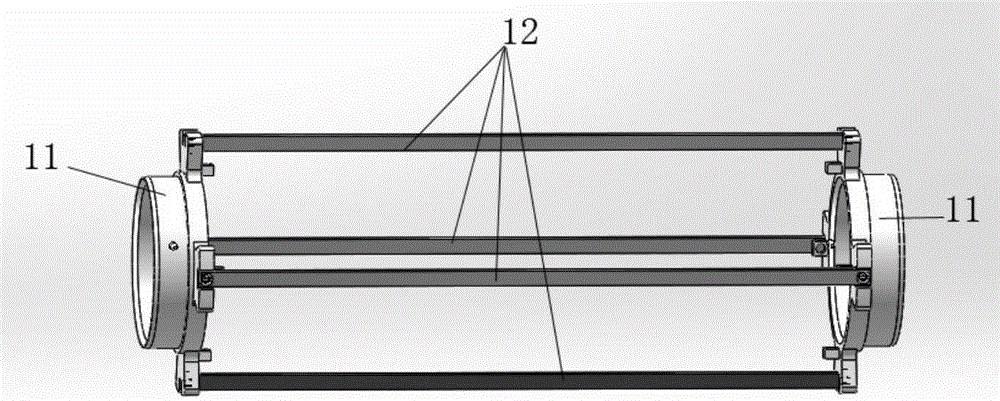

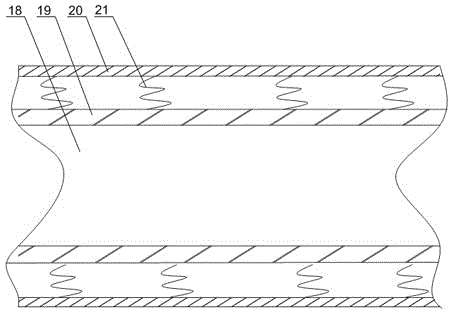

The invention belongs to the technical field of optical fiber sensing, and in particular relates to a fiber optic vector hydrophone with a posture self-correcting function. The vector hydrophone is special for a towed sonar array, and can realize the posture self-correcting in a roll direction of the vector hydrophone, so as to reach the aim that all vector hydrophone element postures in the array are automatically kept consistent. The invention specifically designs a suspension support system with a bias center of gravity, the system is fixedly connected with the vector hydrophone and can freely rotate. According to a principle of dynamics, the vector hydrophone can automatically keep a state of lowest center of gravity, so as to ensure that all elements of the array are kept in the same posture. The fiber optic vector hydrophone provided by the invention is applicable to the control on the posture of a towed vector array vector hydrophone, and also applicable to the control on the posture of a towed array posture sensor, and can ensure that the posture sensor in the towed array is kept in a horizontal state all the time, so as to improve the measuring accuracy of the posture sensor.

Owner:NAT UNIV OF DEFENSE TECH

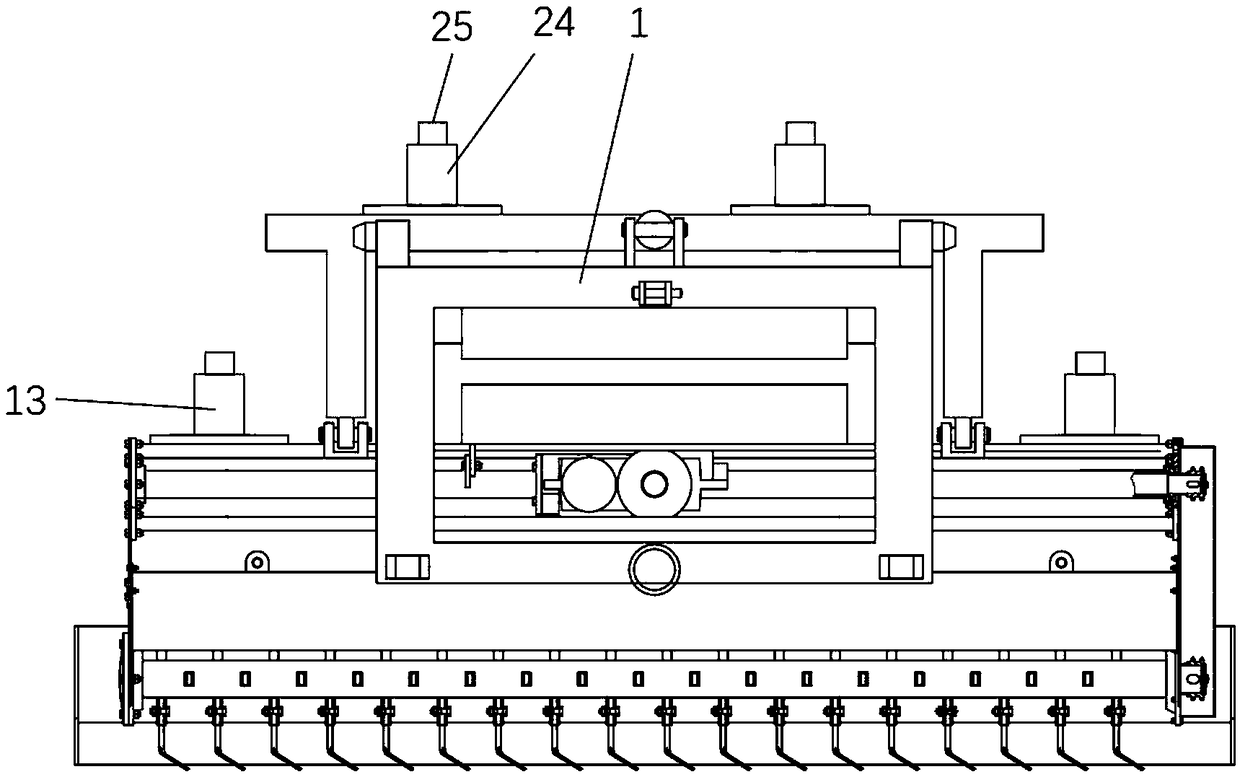

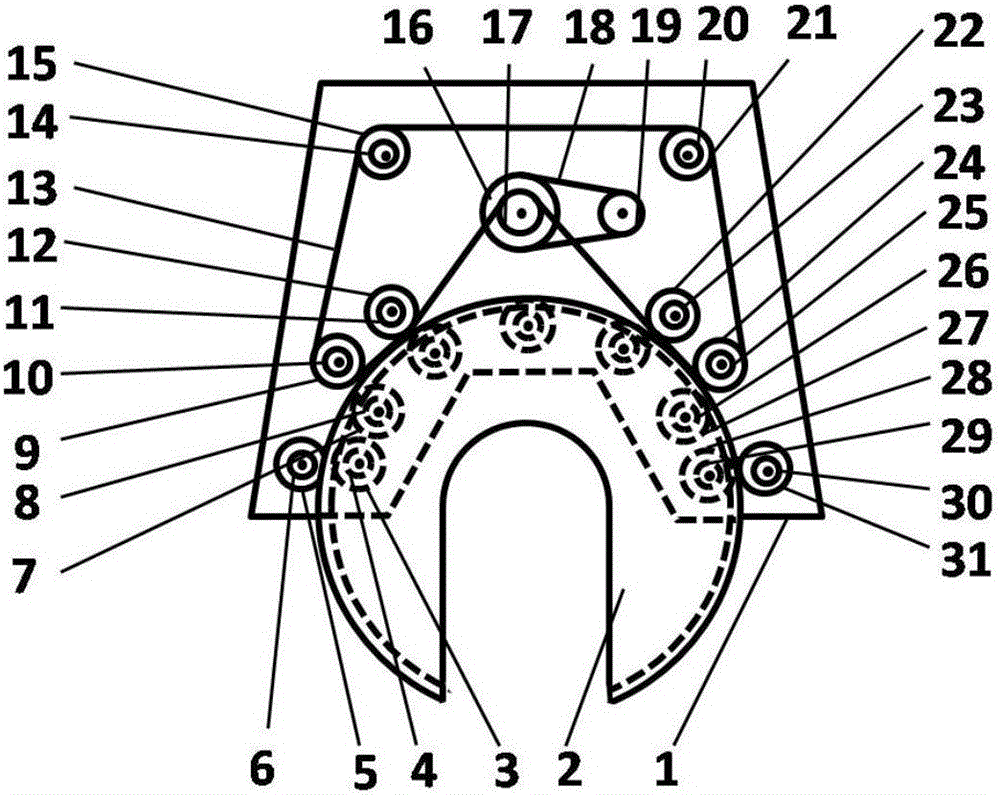

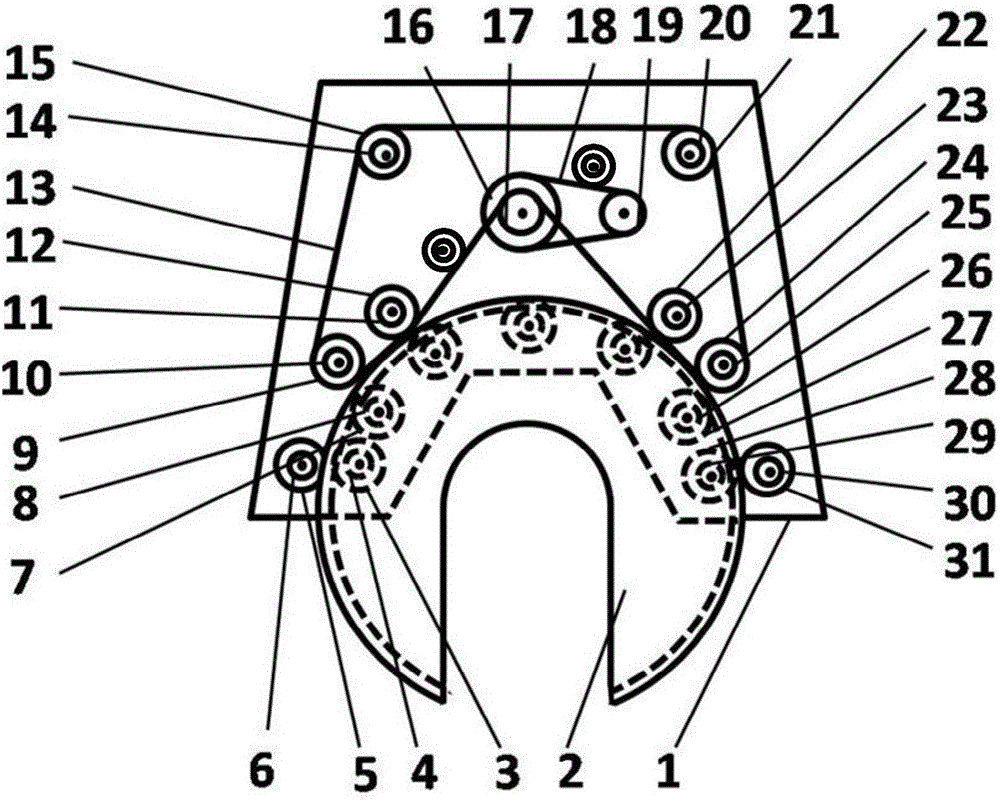

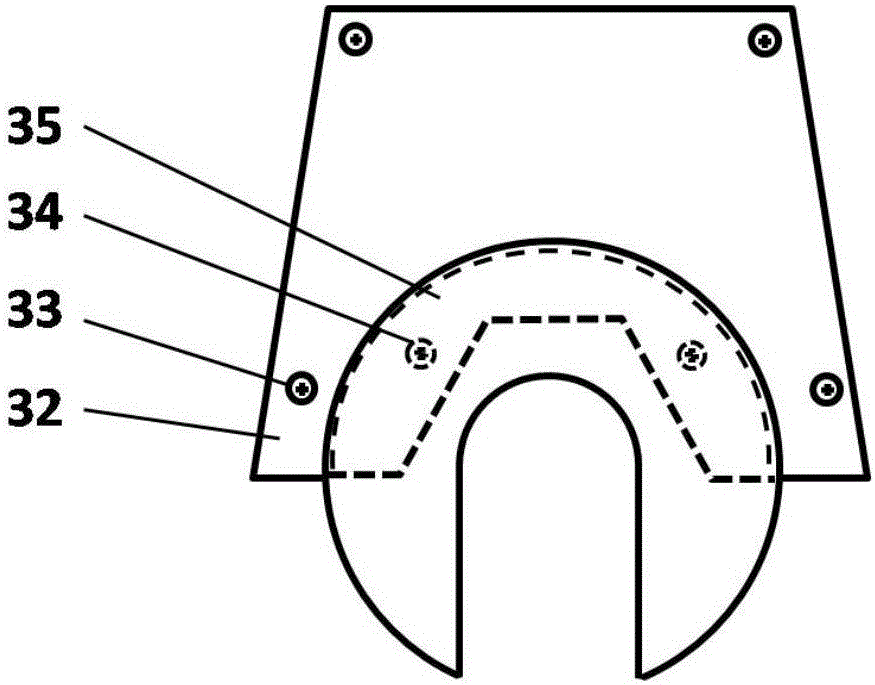

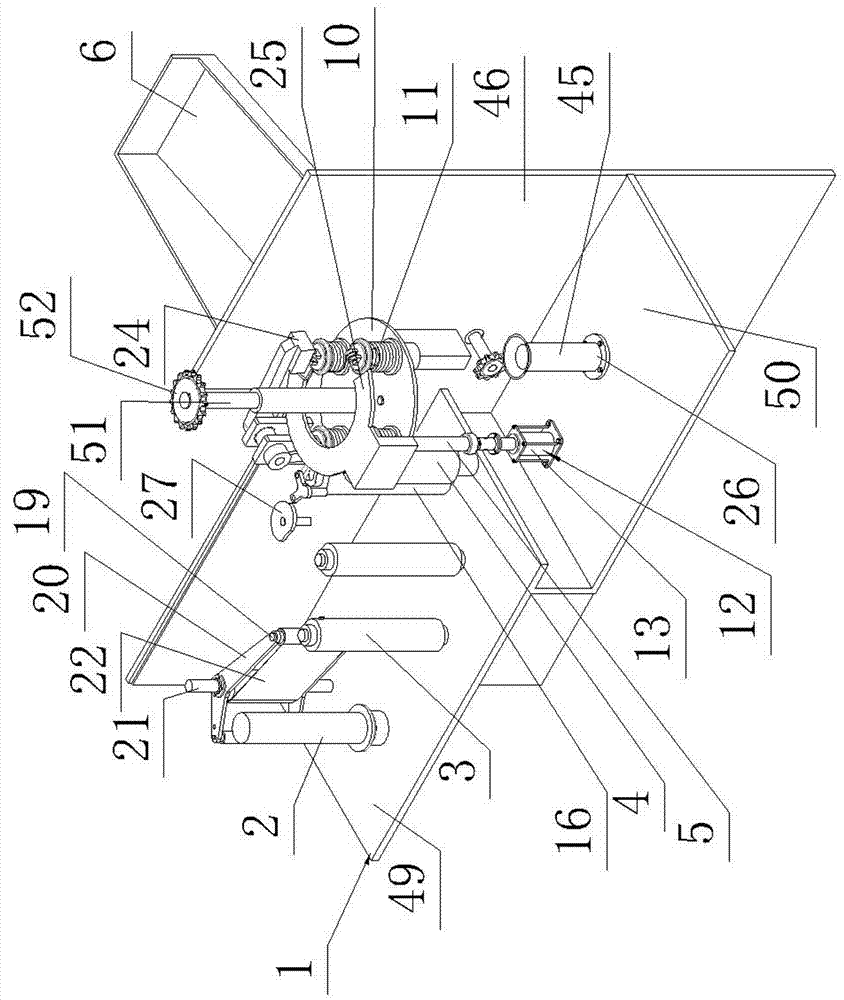

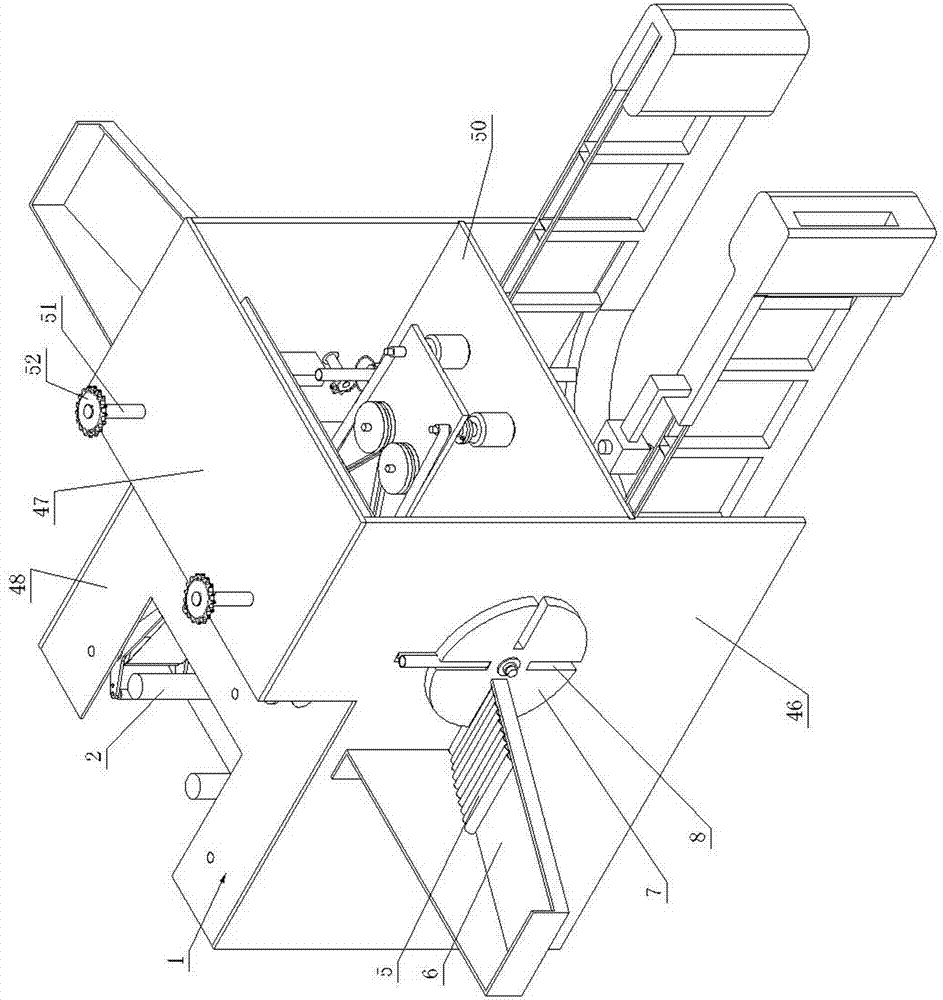

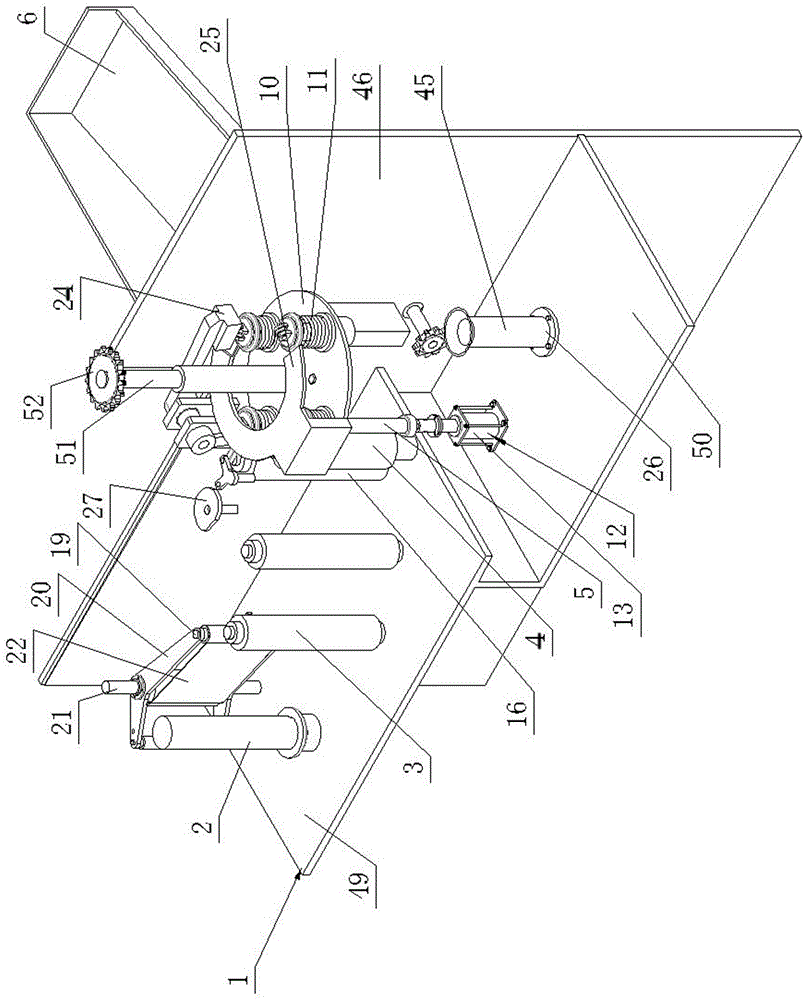

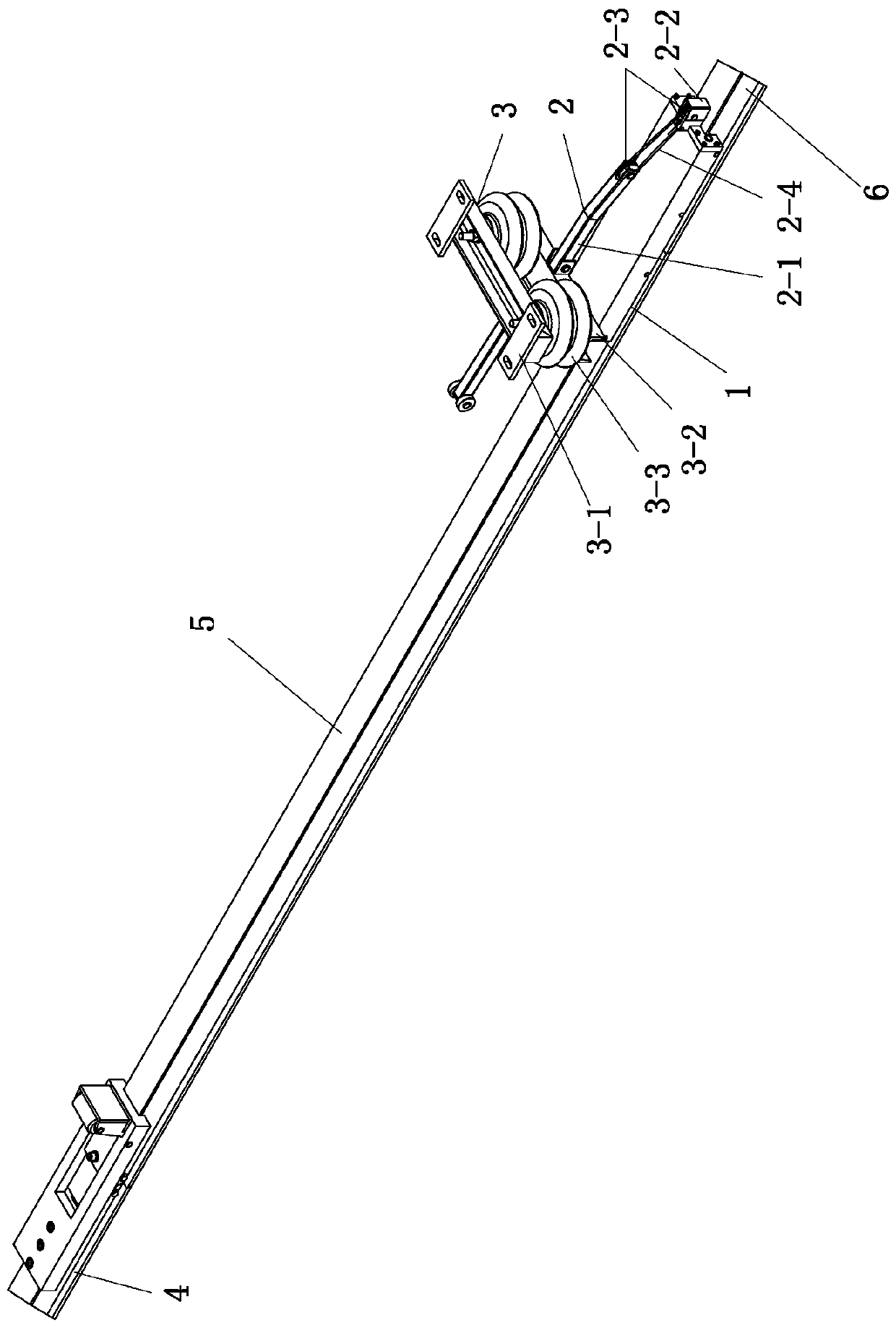

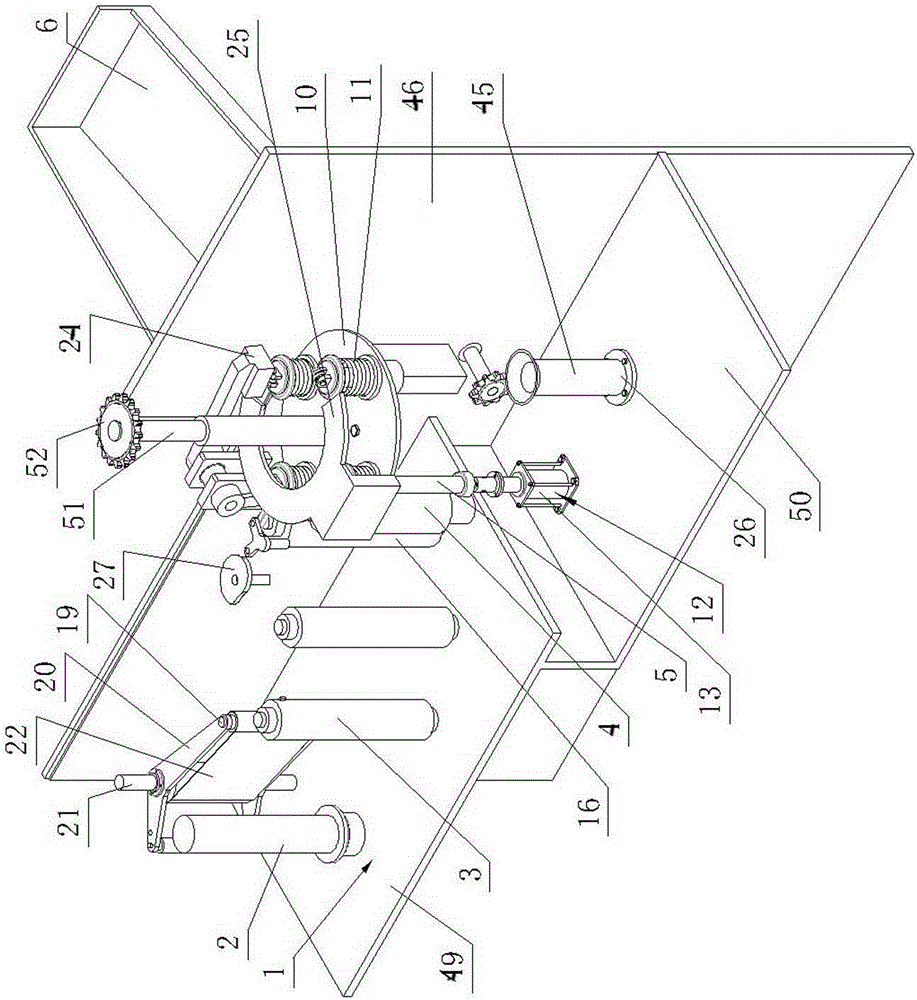

Self-balancing slurry harrowing and soil flatting operation machine for paddy field

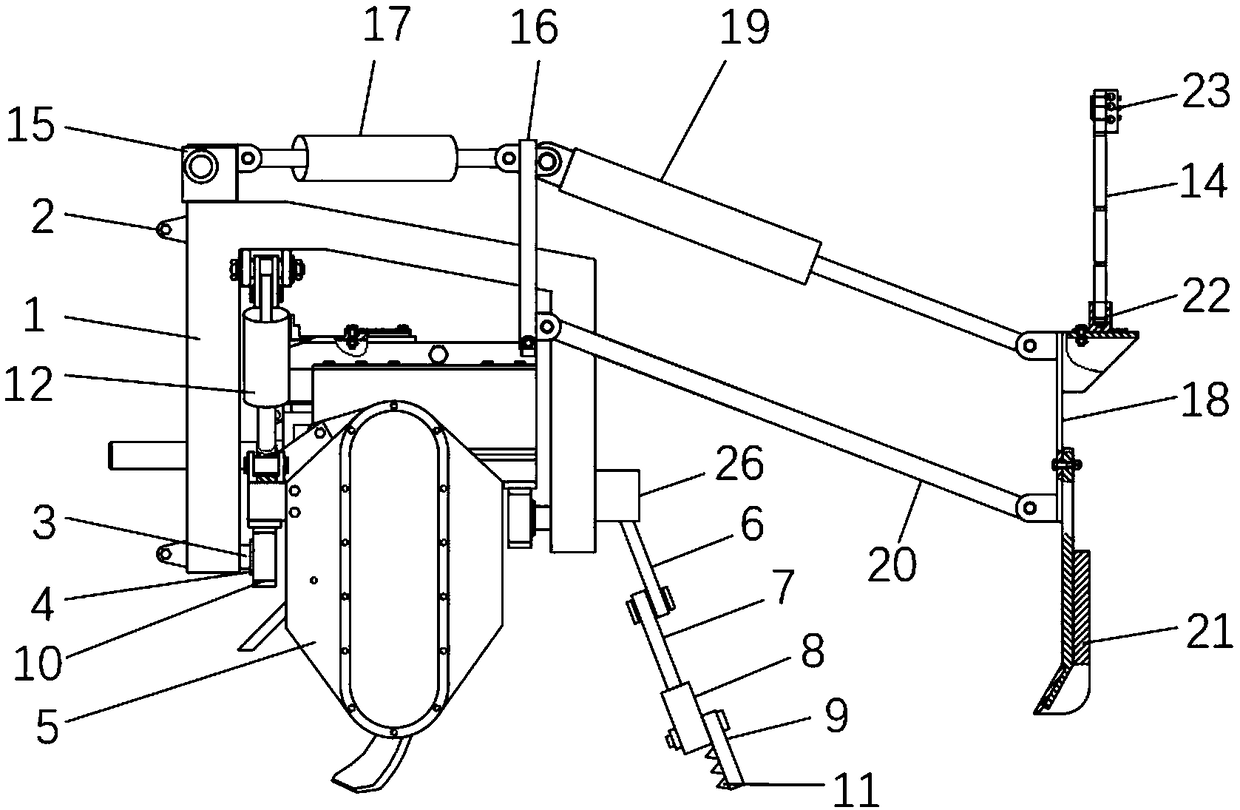

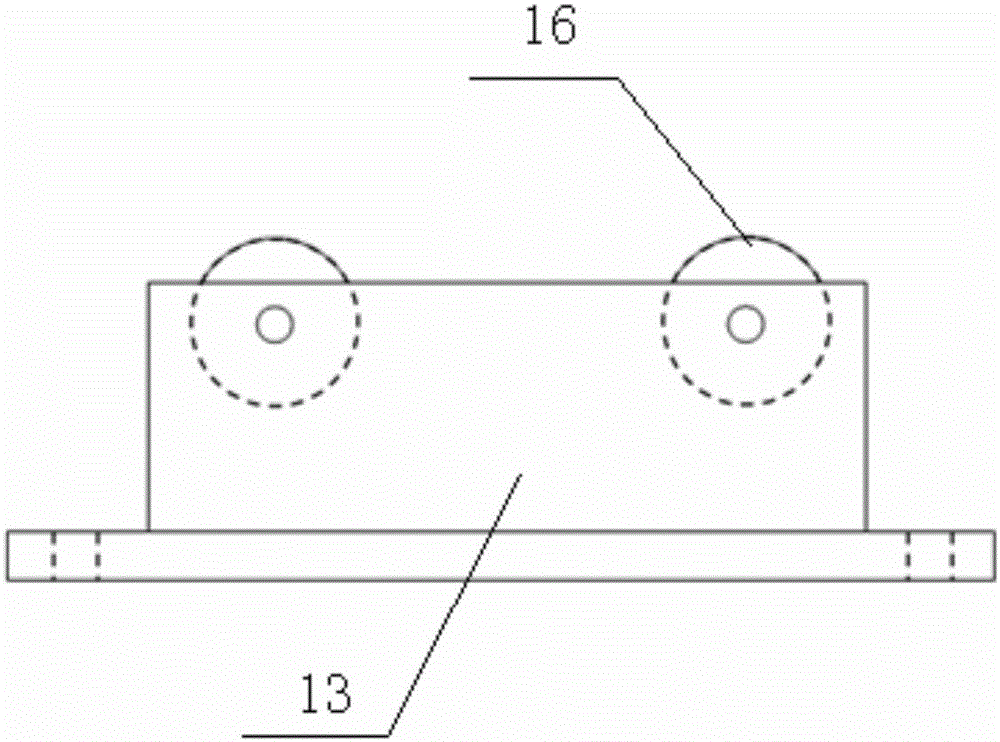

ActiveCN109220014AGuaranteed free spinsConsistent rotary tillage depthSpadesAgricultural machinesEcological environmentWater resources

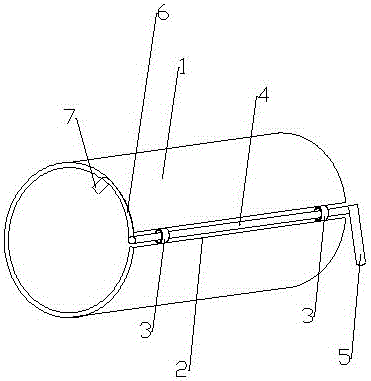

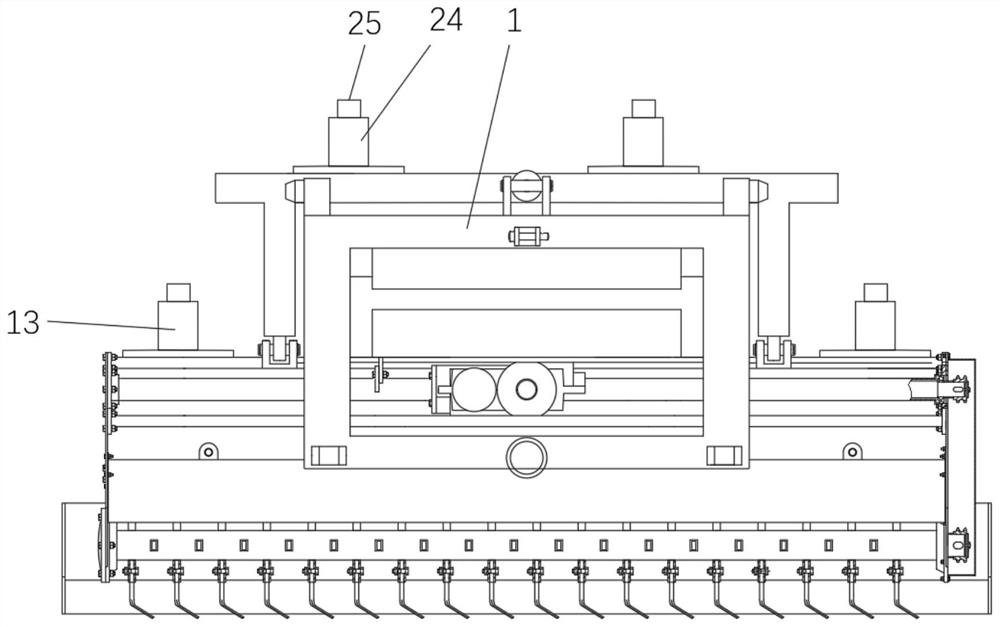

The invention discloses a self-balancing slurry harrowing and soil flatting operation machine for a paddy field. The self-balancing slurry harrowing and soil flatting operation machine comprises a rotary support and a slurry harrowing machine body, and is characterized in that a bearing pedestal is installed below the middle of a front cross beam of the slurry harrowing machine body, a three-pointsuspension is welded to the front end of the rotary support, the front end of the rotary support is connected with a tractor, and rotating shafts are welded to the middles of a front cross beam and arear cross beam below the rotary support. The self-balancing slurry harrowing and soil flatting operation machine has the advantages that during operation, the left-and-right and horizontal inclination angle of the slurry harrowing machine body can be automatically adjusted, rotary tillage depth is free of influences of unevenness of the paddy field surface, slurry harrowing, stub burying and soil flatting operation can be completed at a time, and grinding pressure of the tractor on the paddy field is reduced. After the operation, the height differential value of paddy field blocks is small,the utilization rate of water resources can be increased, water consumed for irrigation can be saved greatly, intermittent irrigation is easy, accurate water consumption is realized, and the efficiency of irrigation reaches 90%. Meanwhile, fertilizer loss and fertilizer shortage are reduced, and the utilization rate of chemical fertilizer is increased by 10% or more. Fundamentally, the ecologicalenvironment of whole countries is protected, and discharging of harmful substances is controlled.

Owner:HUAIHAI INST OF TECH

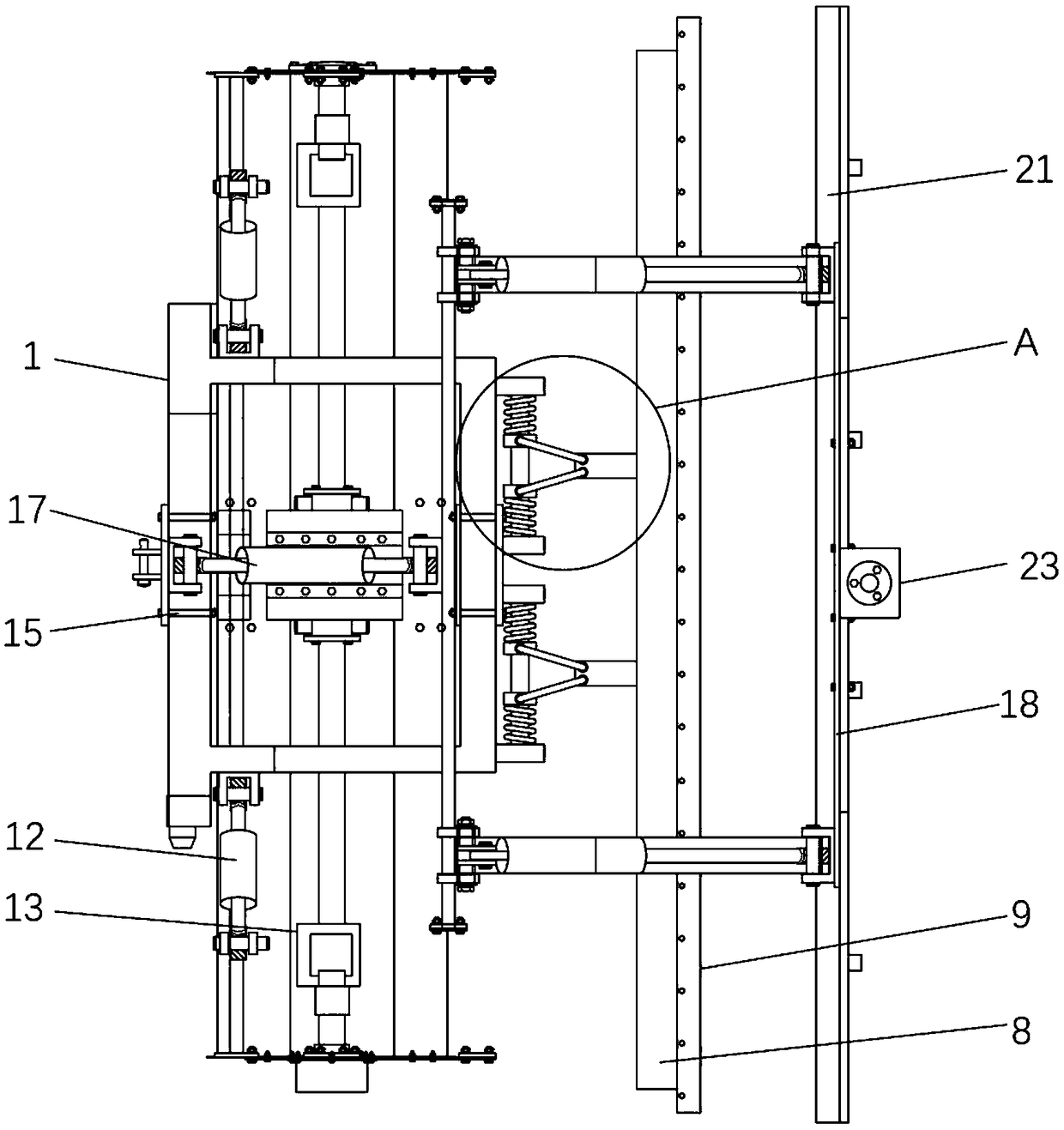

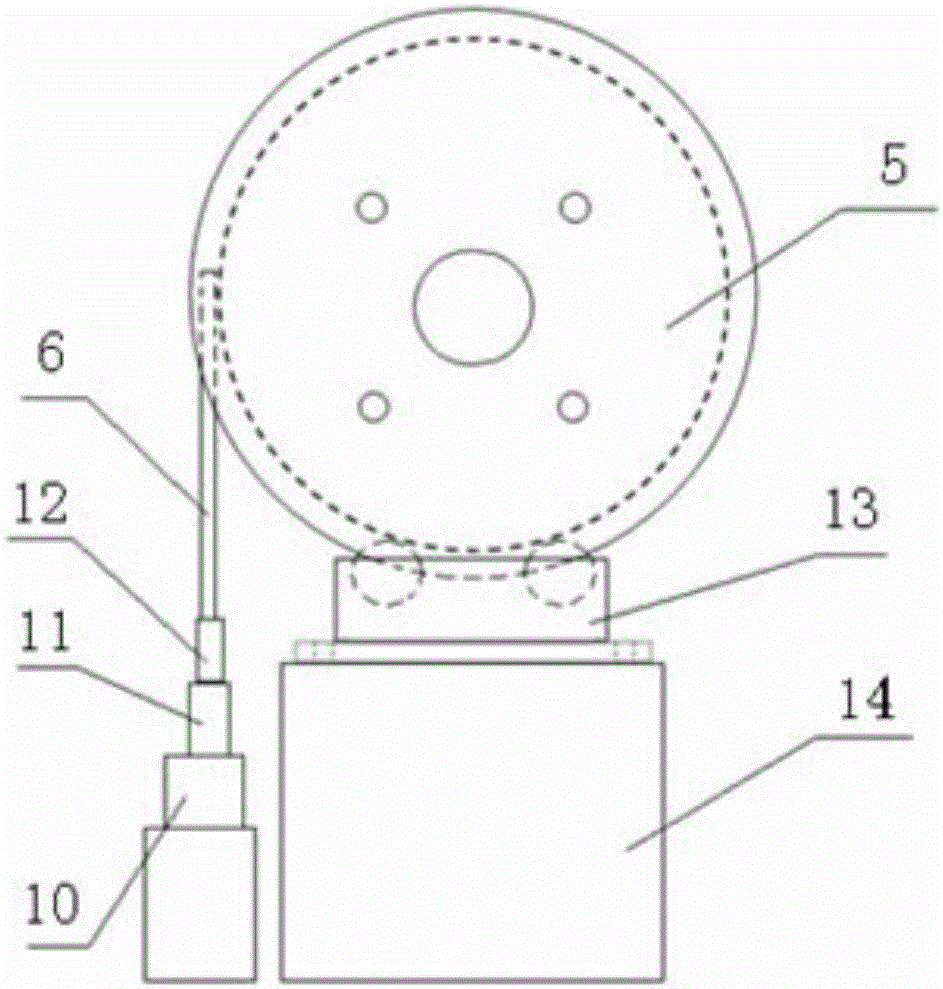

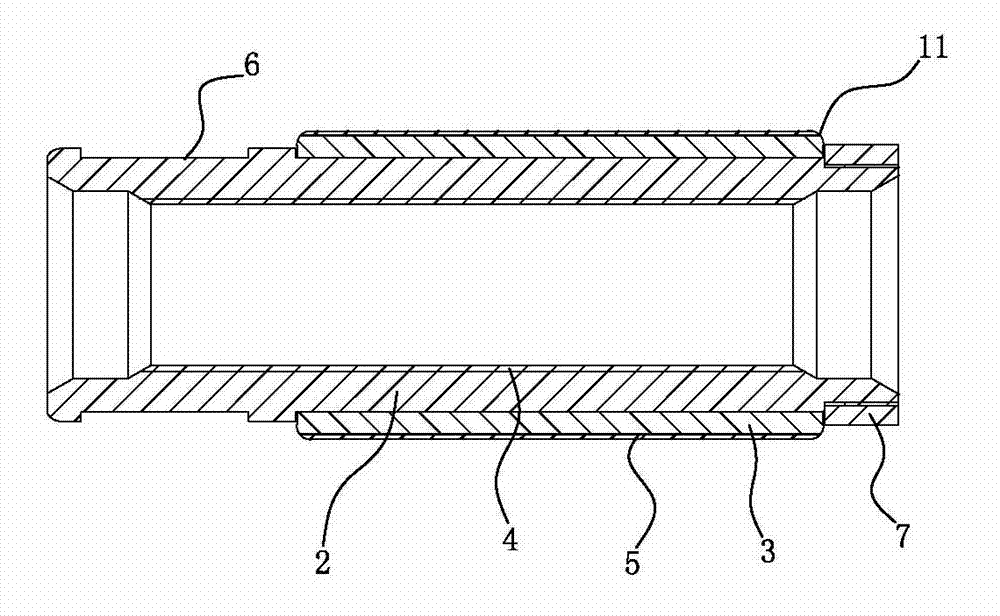

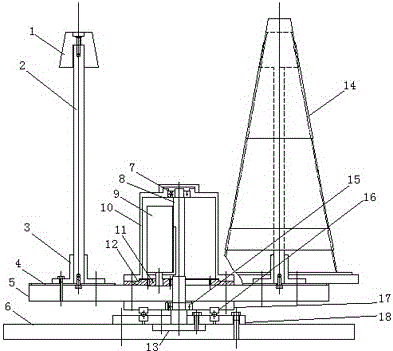

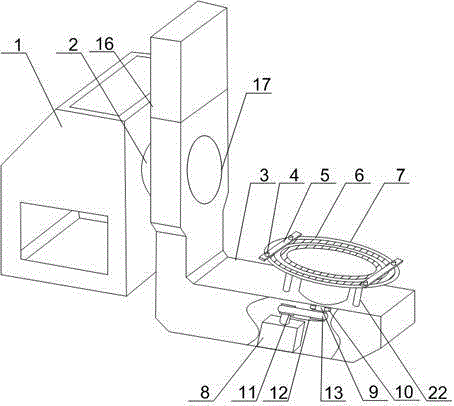

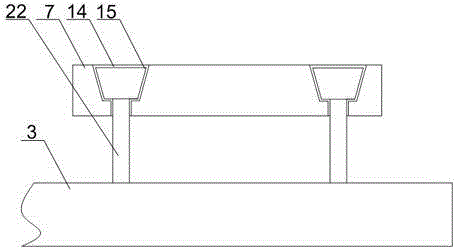

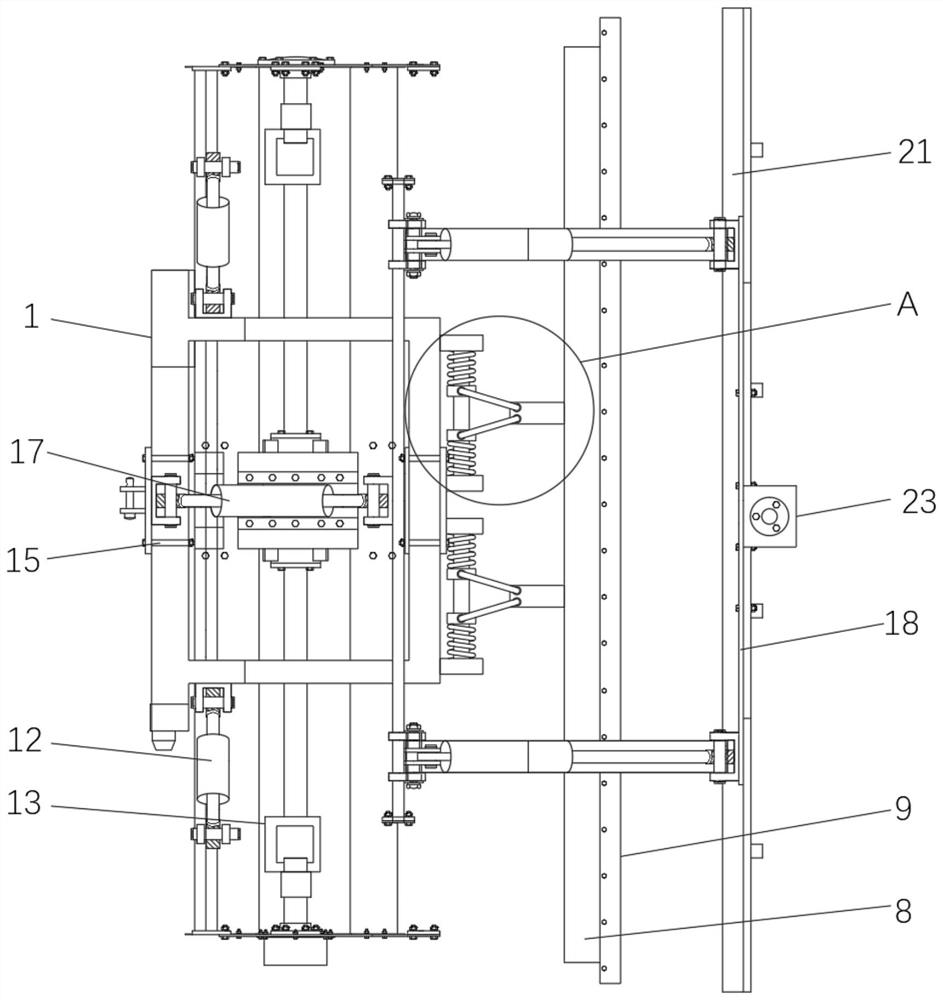

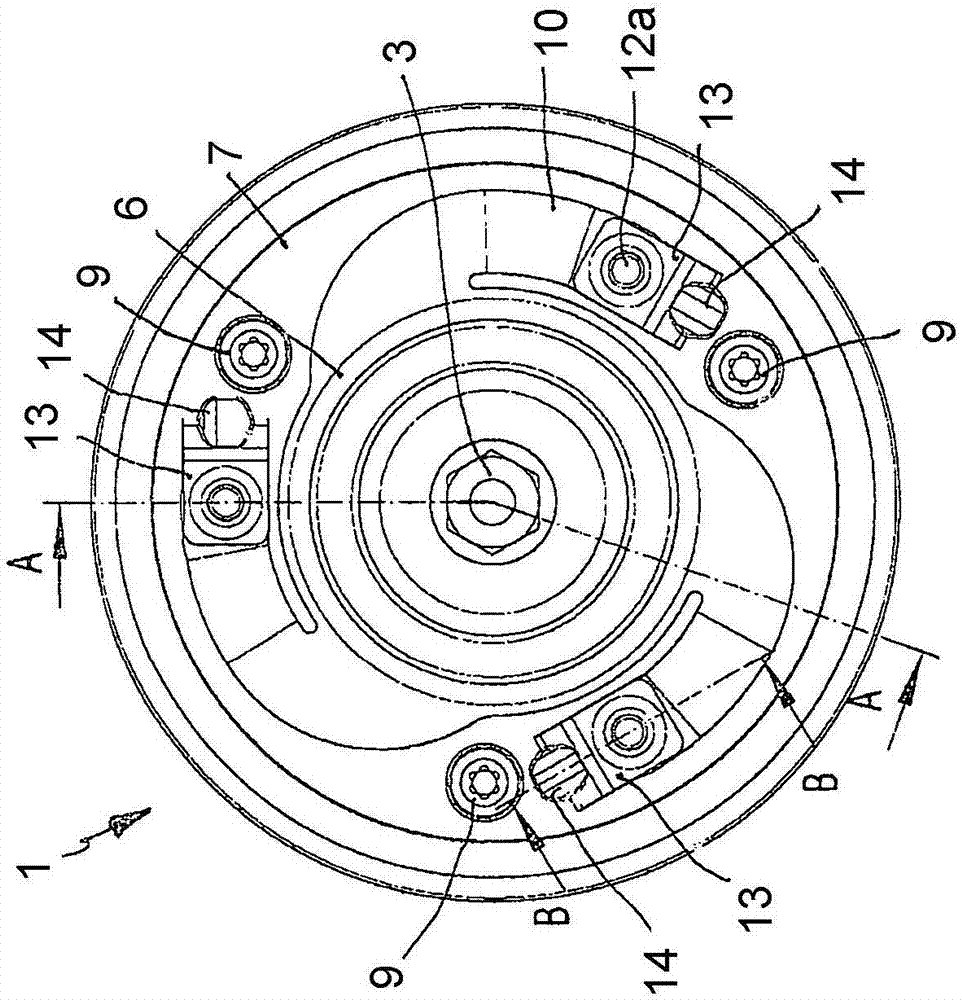

Hollow interlayer steel pipe concrete column tension-torsion test loading device

InactiveCN106483027AGuaranteed free spinsSmooth rotationMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesPull forceTorsion test

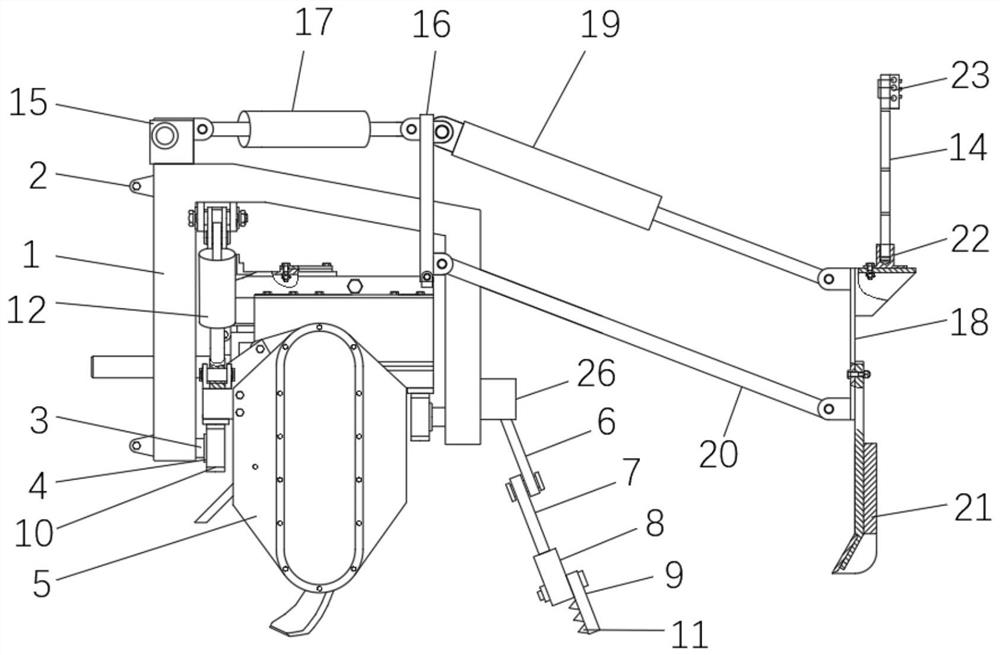

The invention relates to a hollow interlayer steel pipe concrete column tension-torsion test loading device. The loading device comprises a counterforce pier, a pressure bar, a connection board, a disc, a horizontal pulling jack, a horizontal tension transducer, a tension bearing, a horizontal tension connecting piece, a roller support, a pedestal, a vertical tension jack, a vertical tension transducer, a vertical tension connecting piece and a wire rope; the horizontal tension jack transmits the pulling force to a hollow interlayer steel pipe concrete column through the horizontal tension transducer, the tension bearing, and the horizontal tension connecting piece, the tension bearing is used for freely rotating the hollow interlayer steel pipe concrete column; the vertical tension jack is fixed at the disc at the end part of the hollow interlayer steel pipe concrete column for applying torque through the vertical tension transducer, the vertical tension connecting piece and the wire rope, and the roller support is used for offset the vertical force generated when the torque is applied. The hollow interlayer steel pipe concrete column tension-torsion test loading device solves the problem that the torque change rule is inconstant during rotation and test processes when the tension is applied in the test.

Owner:SHENYANG JIANZHU UNIVERSITY

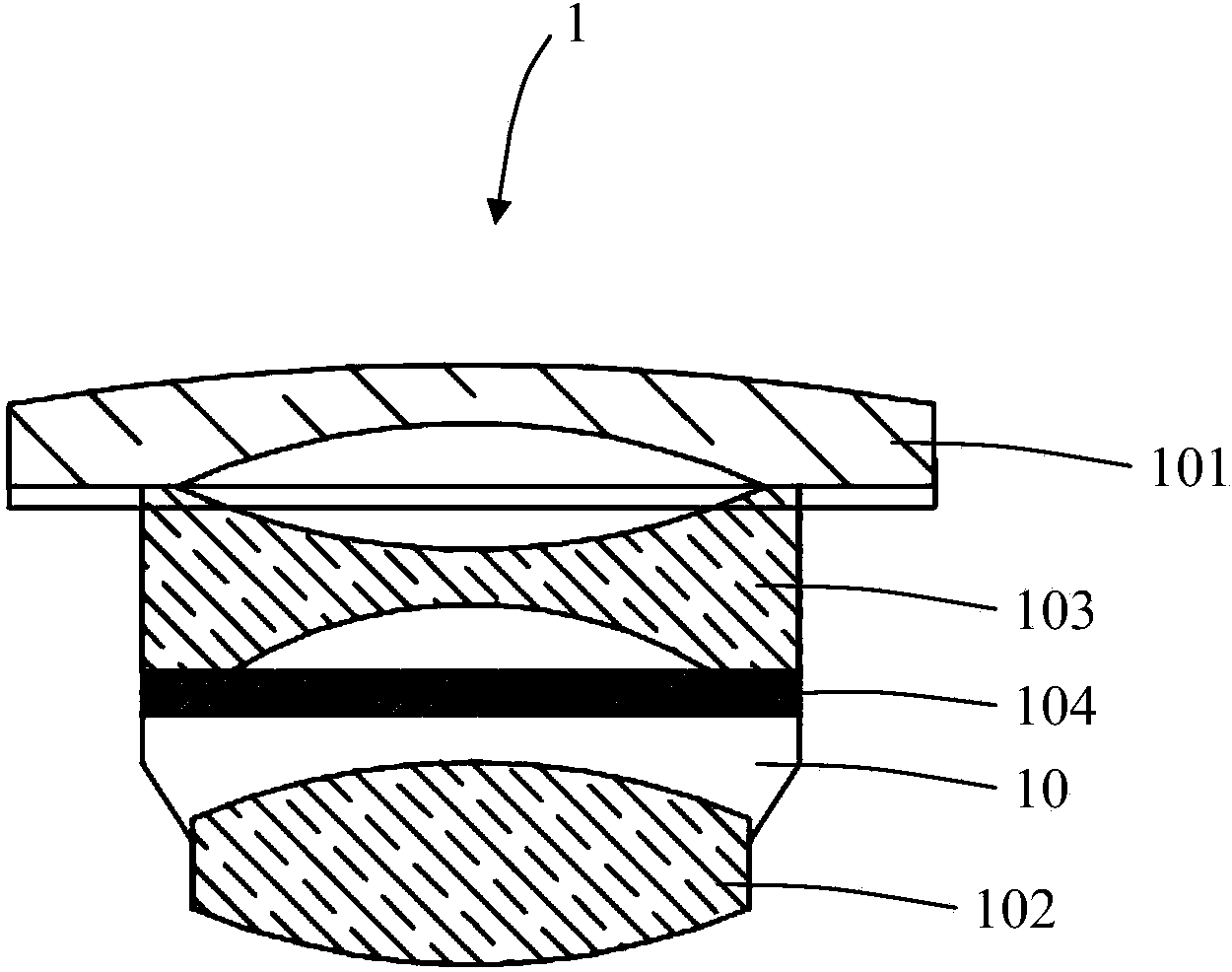

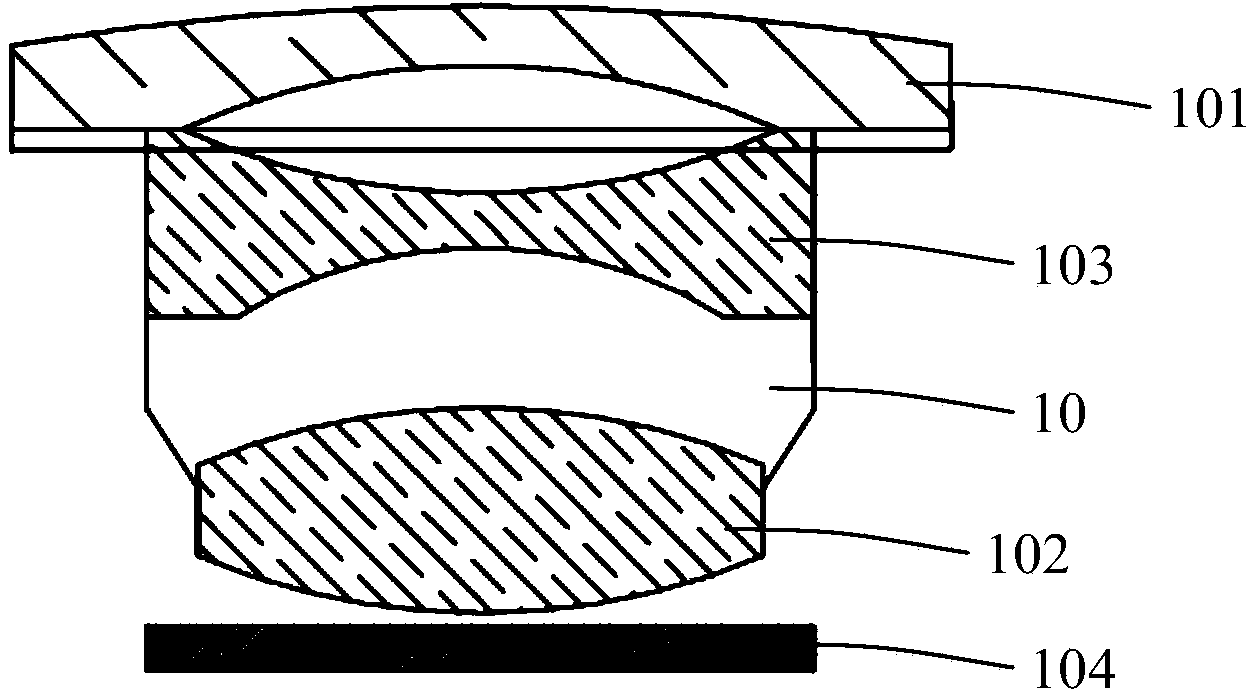

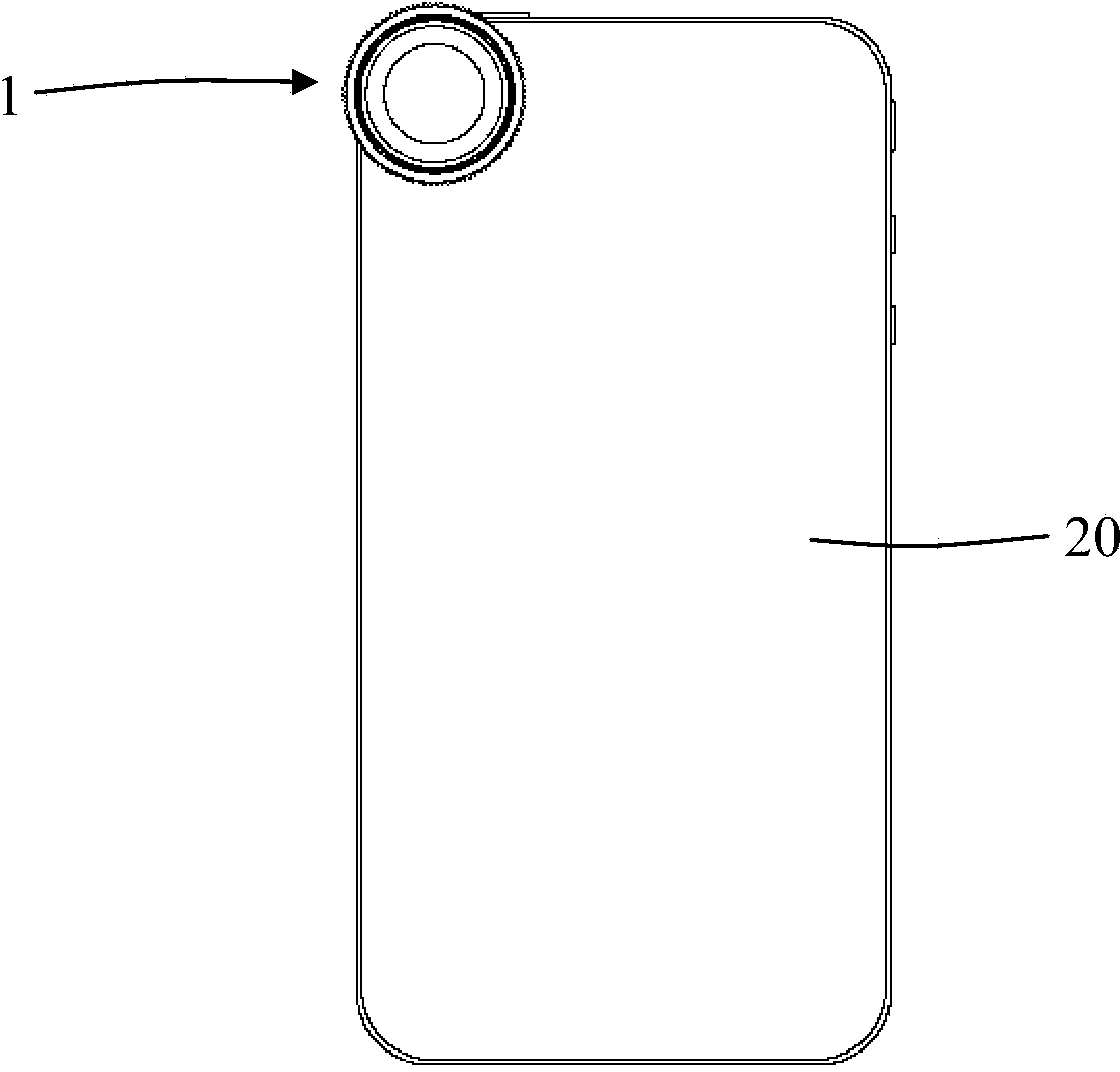

Fish-eye lens

The invention discloses a fish-eye lens. The fish-eye lens comprises a frame and a lens assembly which is arranged in the frame, wherein a circular polarizer is combined in the lens assembly; the fish-eye lens is detachably arranged on a lens of external equipment through a mounting structure and can rotate freely along the circumference. According to the fish-eye lens, by additionally arranging a circular polarizer in the lens assembly, unnecessary polarized light is removed, so that the entire picture is clearer, a more transparent feeling is realized, the problem of reflection during photographing is solved, and the photographing effect is clearer; the fish-eye lens is detachably arranged at the lens position of external equipment through the mounting structure, so that free rotation of the fish-eye lens along the circumference is guaranteed.

Owner:吴刚

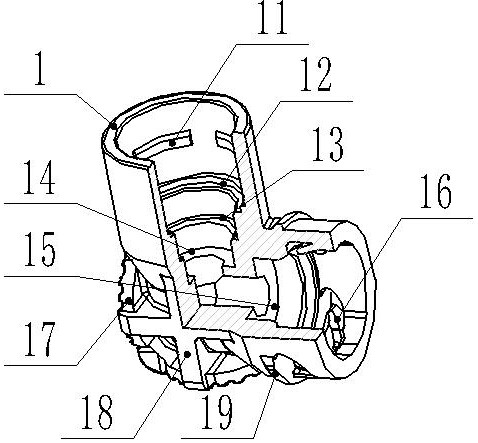

Crucible pulling knife device

The invention relates to a crucible drawing knife device. The crucible drawing knife device comprises a crucible drawing knife body which is of a hollow cylinder structure, wherein the cylinder wall of the crucible drawing knife body is provided with an upper-down penetrated crucible drawing knife body section groove; the crucible drawing knife body section groove is internally fixedly provided with a sleeve ring, the sleeve ring is internally sleeved with a rotating shaft, the bottom of the rotating shaft is movably connected with an arc-shaped rotating rod, and the top of the rotating shaft is movably connected with a rotating handle; the end part of the arc-shaped rotating rod is provided with a drawing knife head, and the length of the arc-shaped rotating rod is not less than the length of the radius of the crucible drawing knife body which is of a hollow cylinder structure; when the crucible drawing knife device is used, firstly the crucible drawing knife body is inserted into a crucible for one time, a material is longitudinally packed, and then the rotating handle is rotated; the rotating handle drives the rotating shaft to rotate, the rotating shaft drives the arc-shaped rotating rod to rotate, the arc-shaped rotating rod can do a circling motion by surrounding the rotating shaft, the drawing knife head is utilized for cutting off the bottom surface of the packed and sleeved extracted material, the crucible drawing knife body is taken out, and the material is pulled out.

Owner:FIVE STAR NEW MATERIAL TECH CO LTD

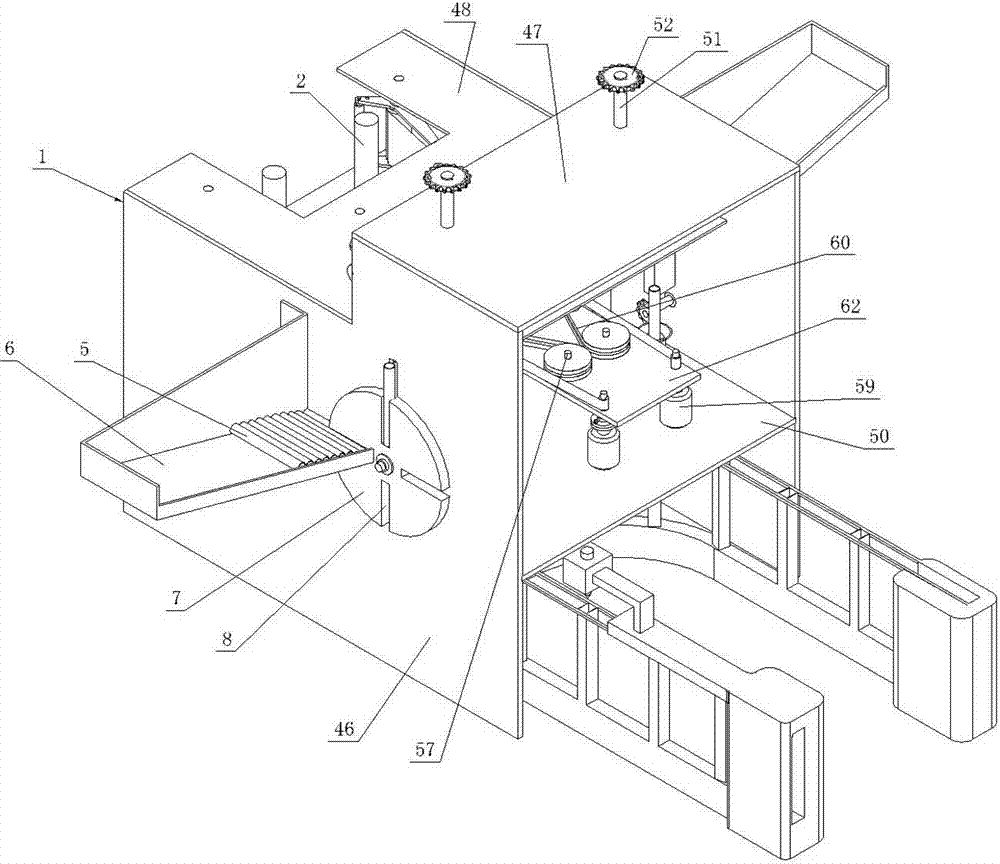

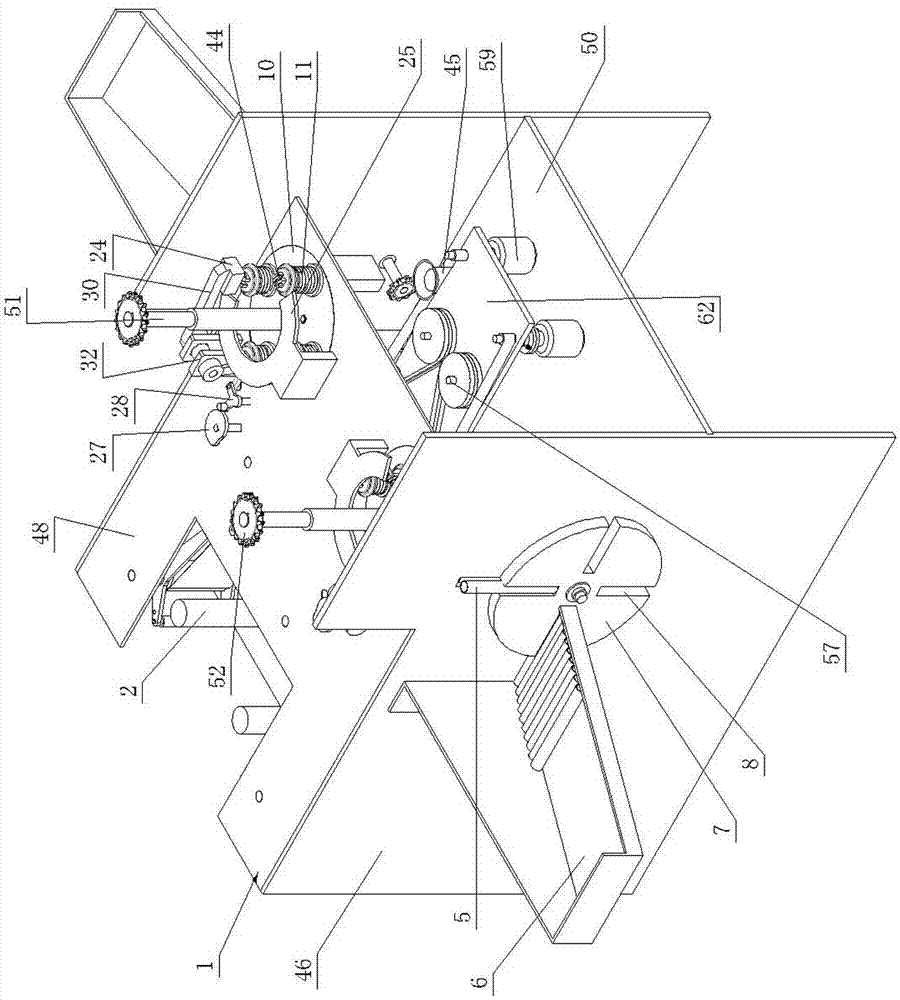

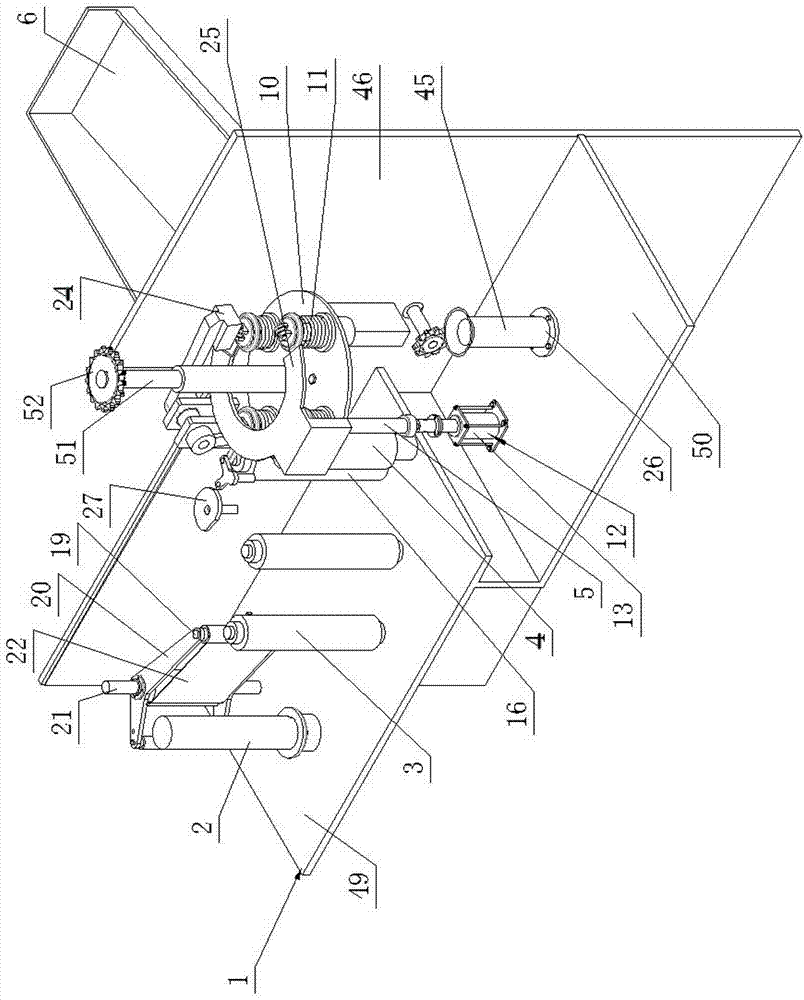

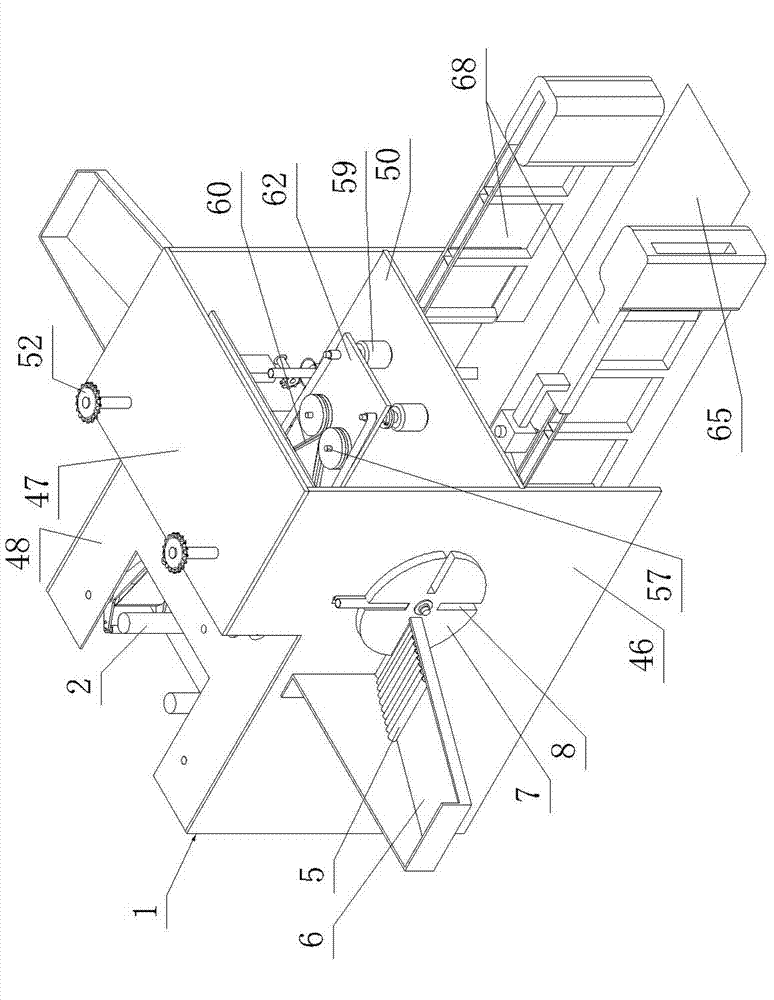

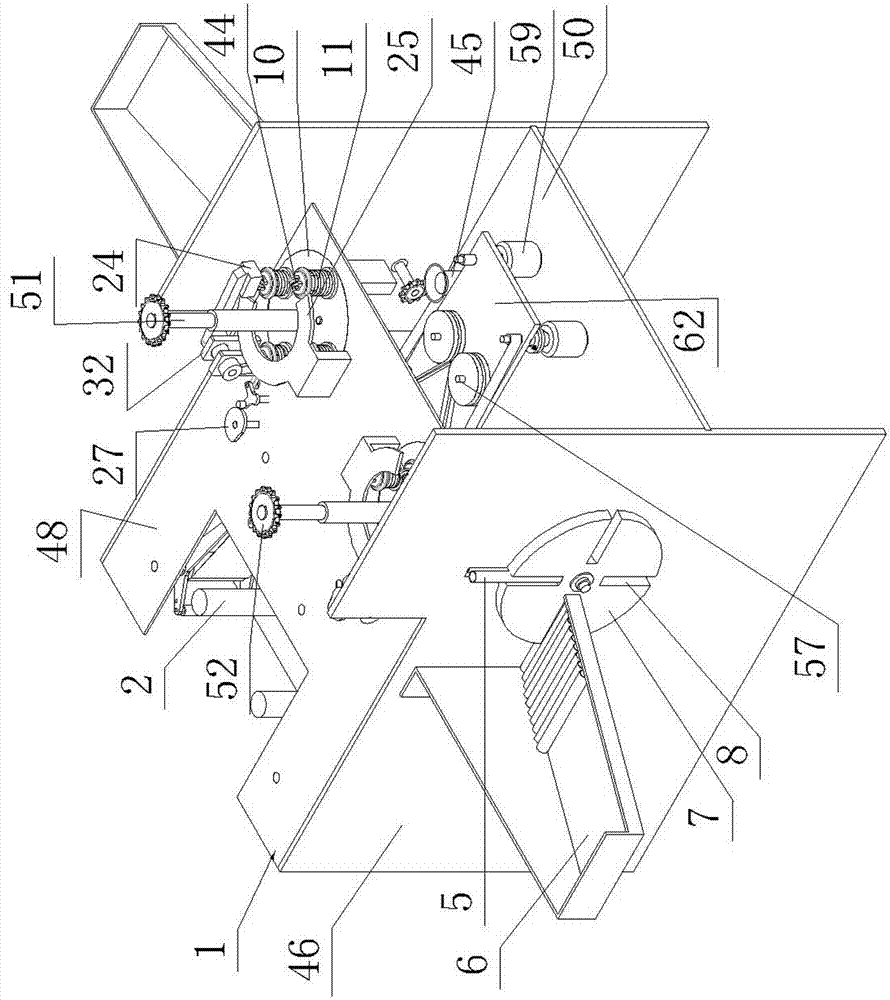

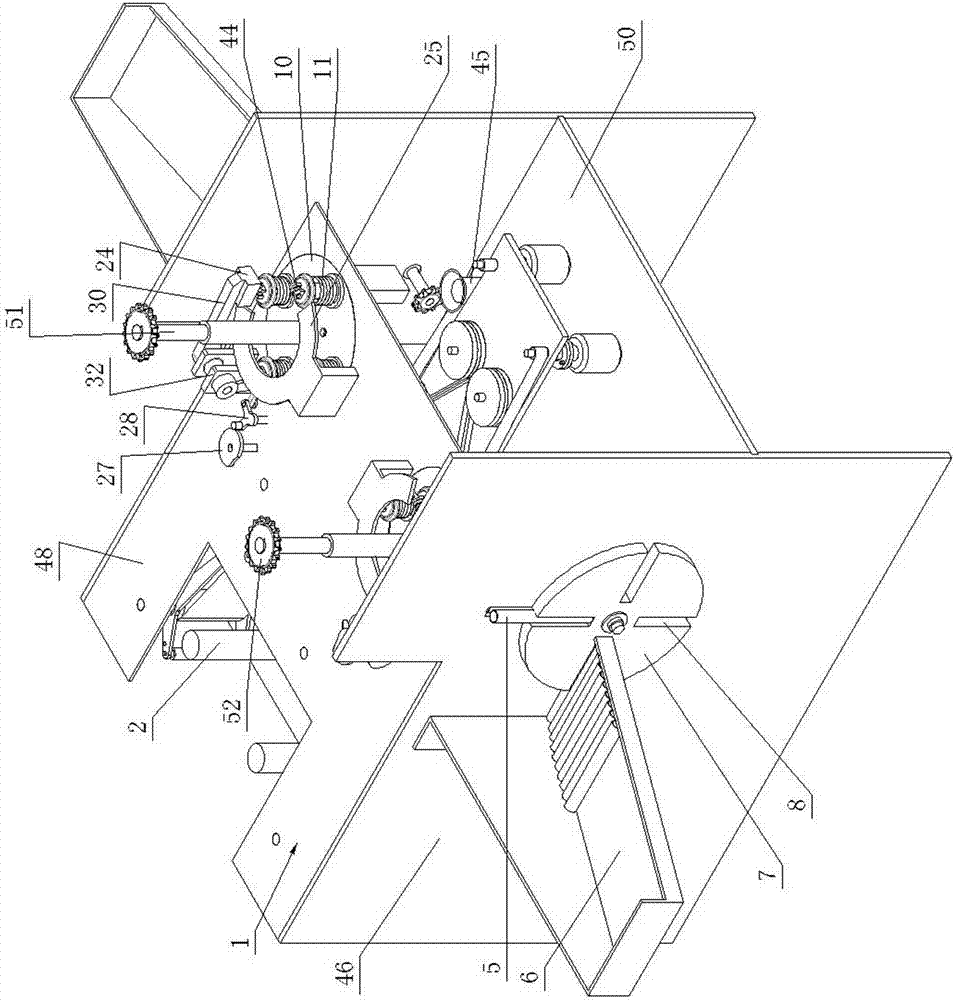

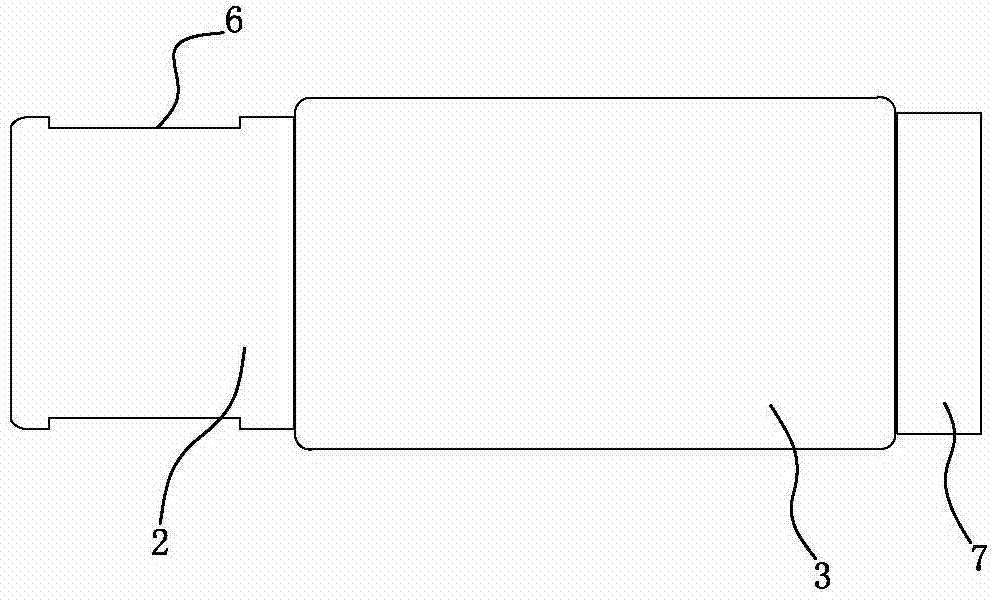

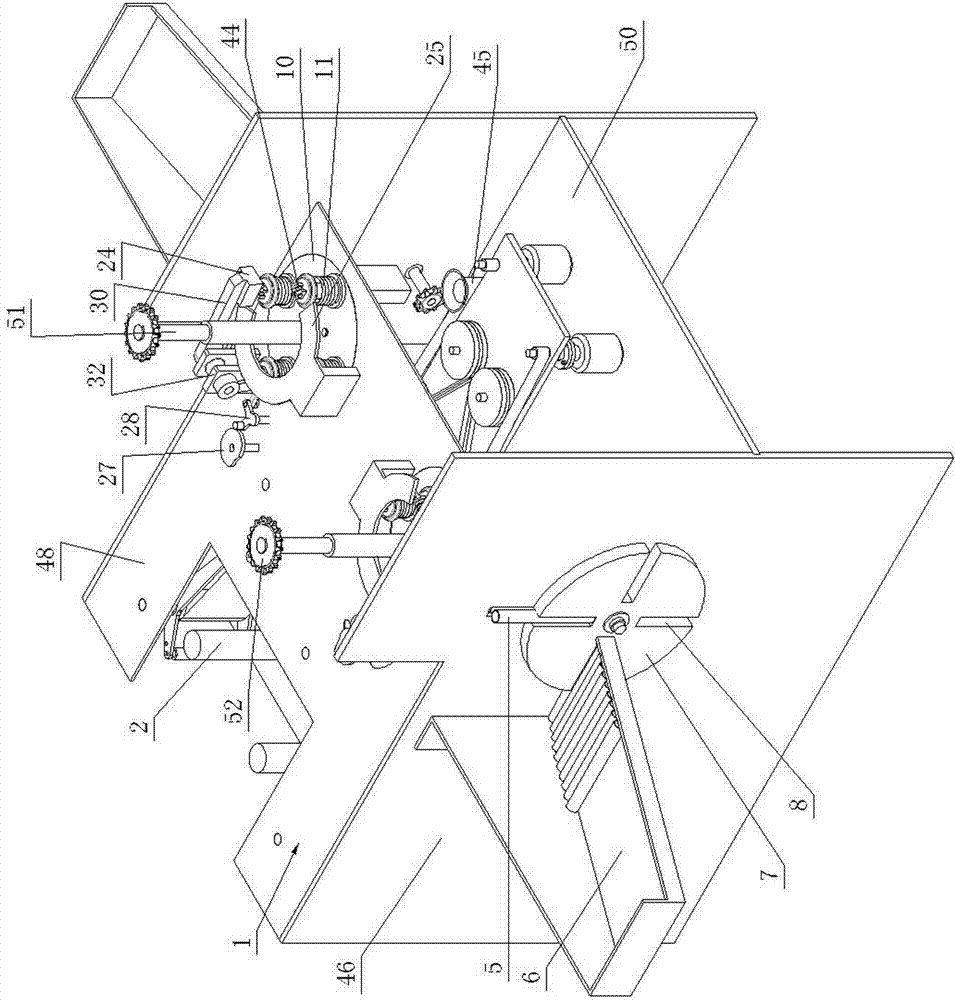

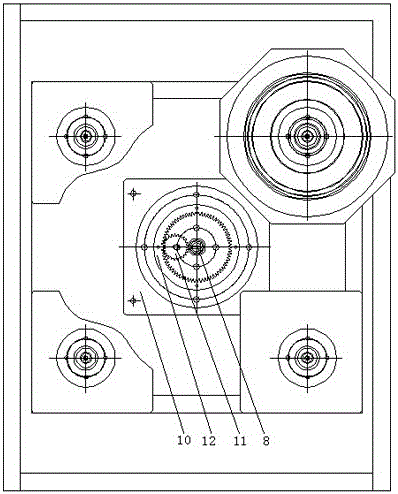

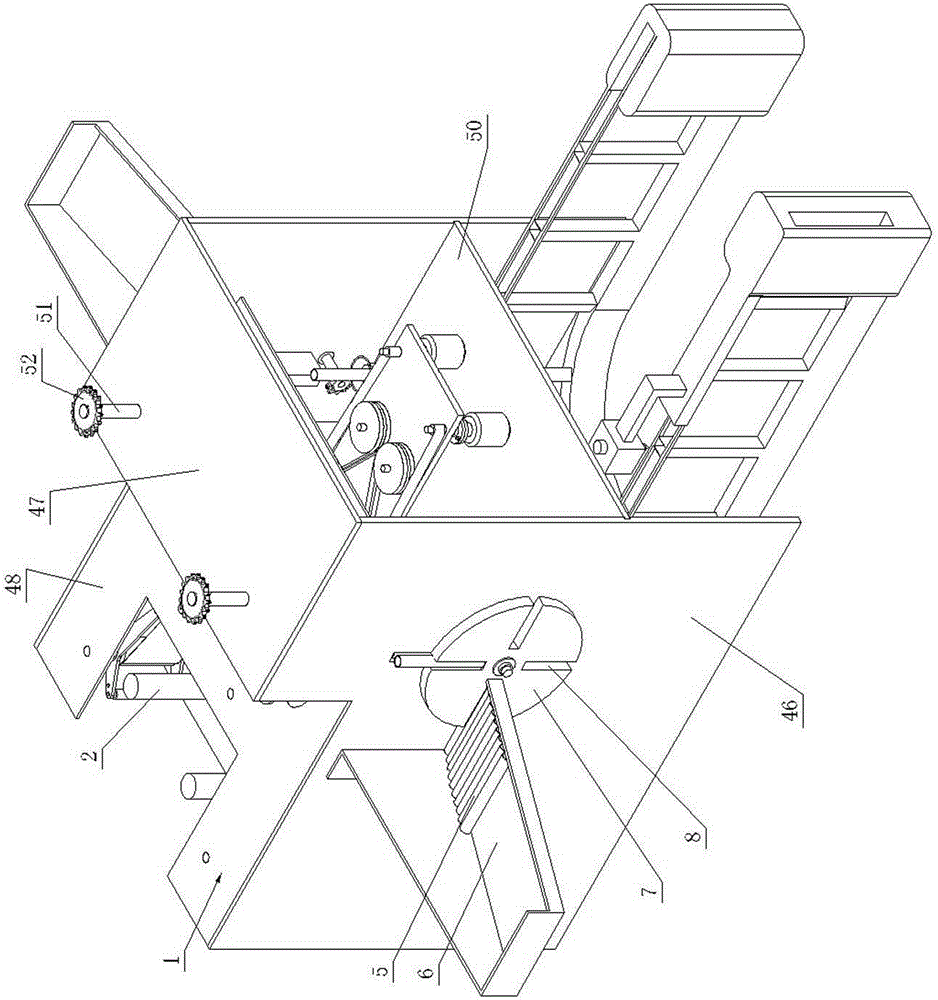

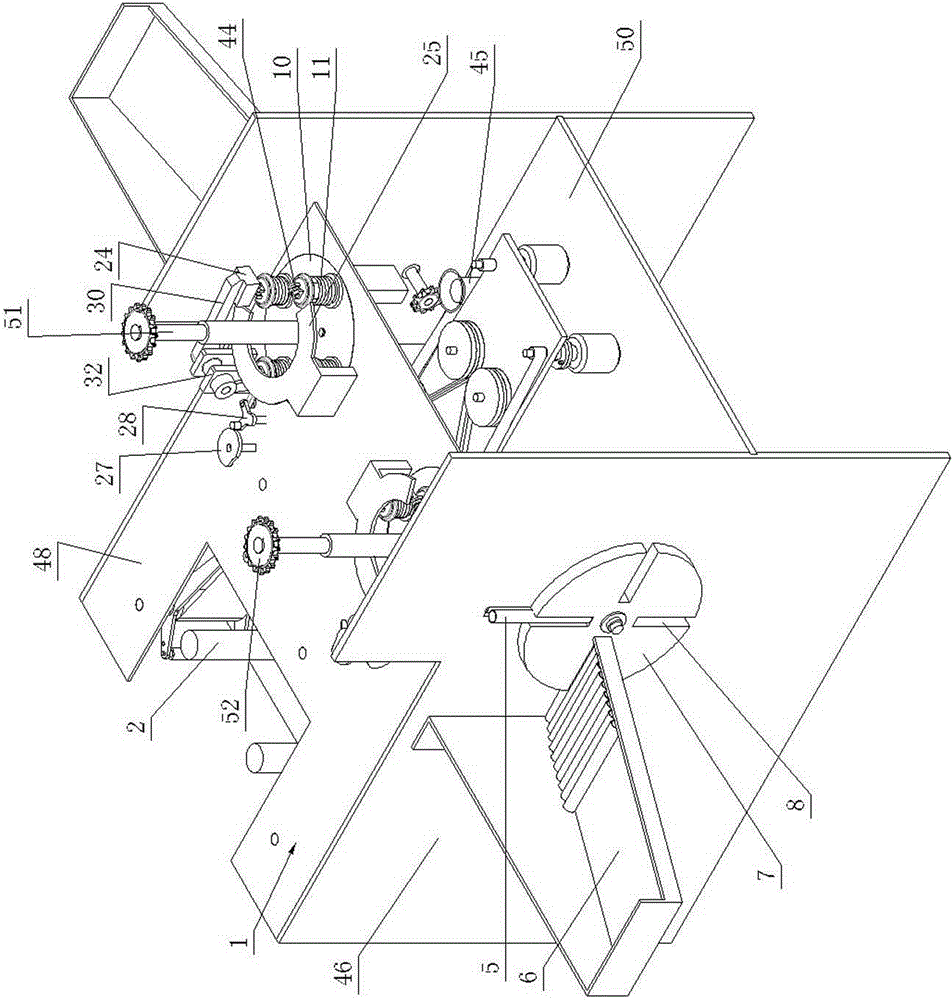

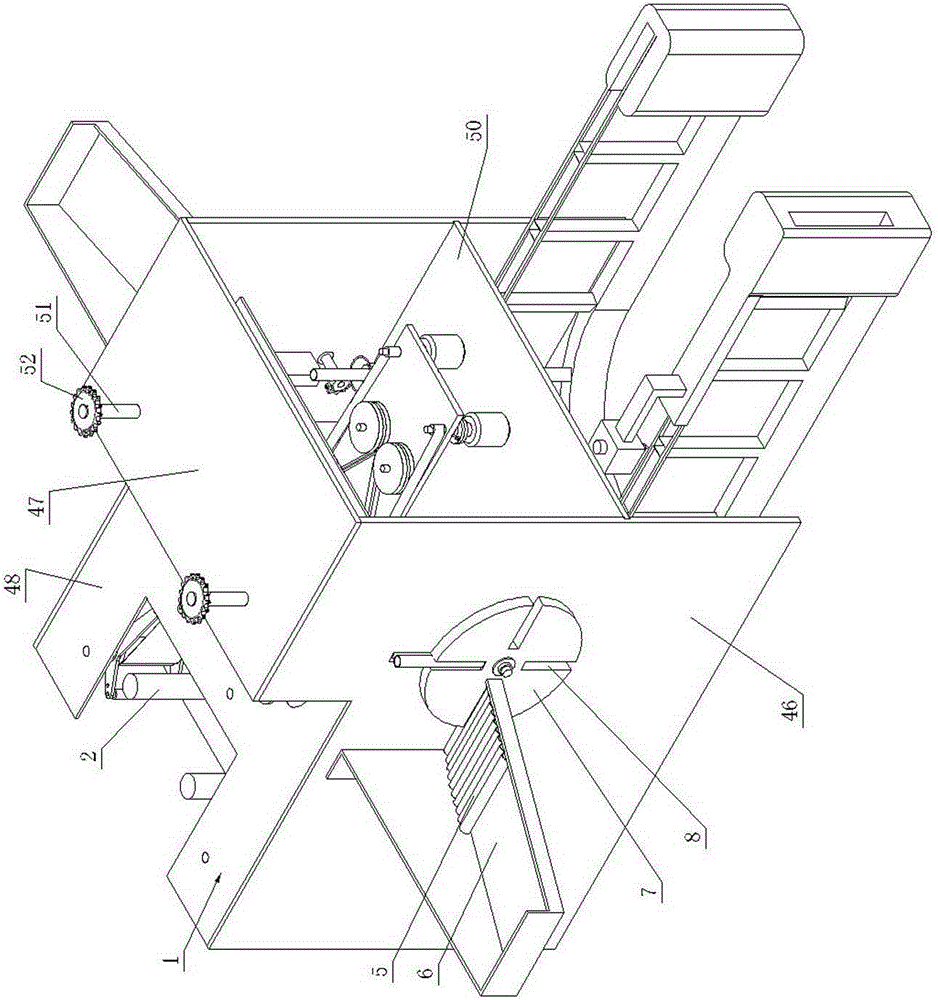

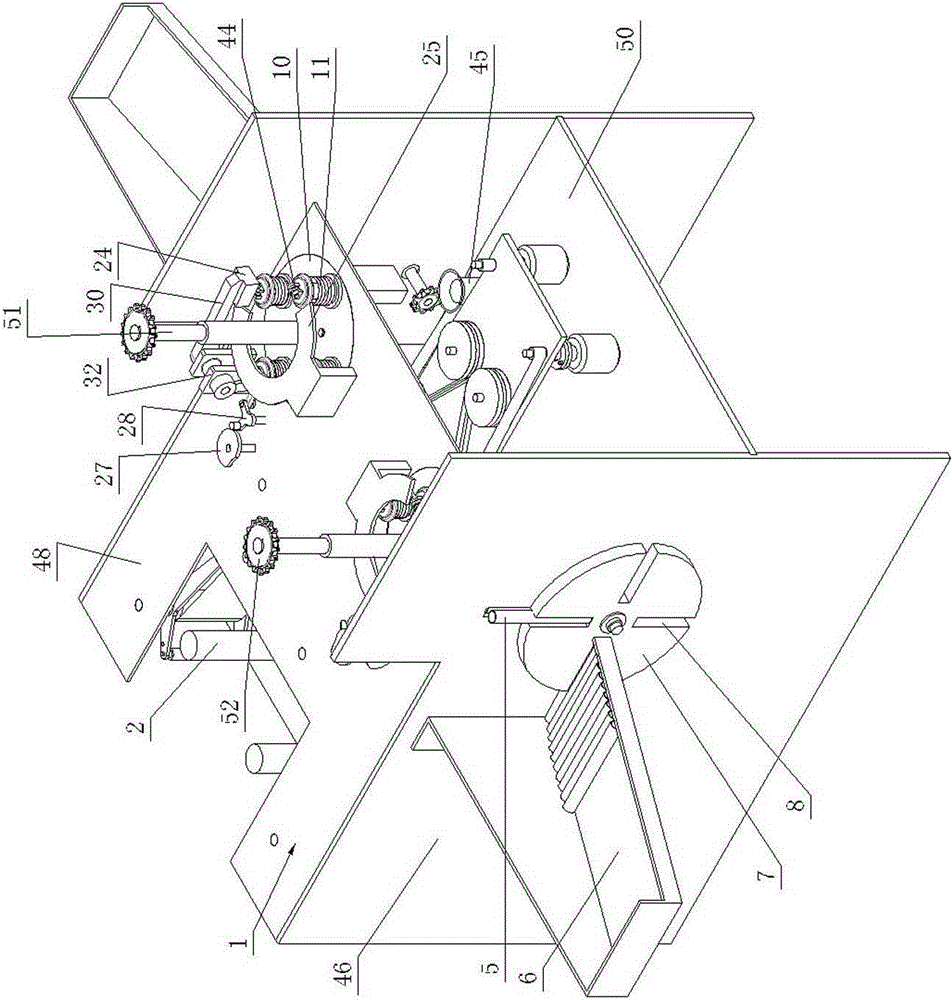

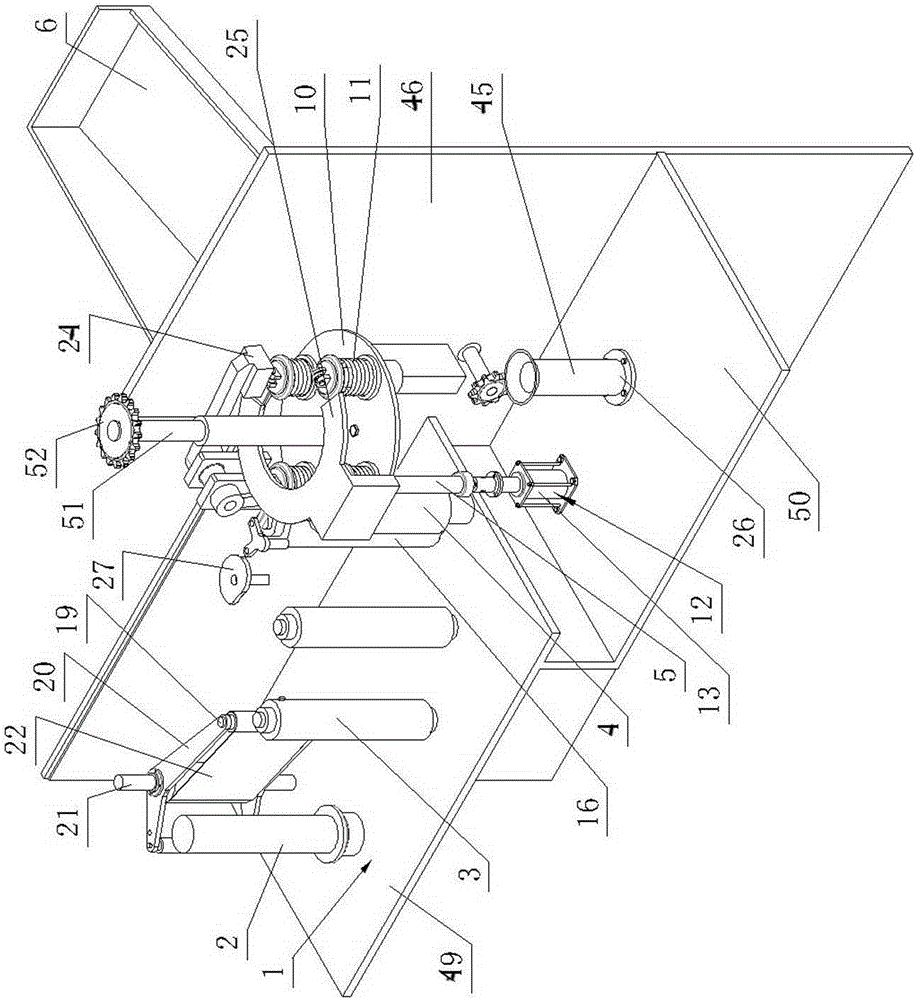

Aluminum foil packaging machine

ActiveCN103935797AThe feeding process is convenientHigh accuracy of operation and positioningWebs handlingPipe supportEngineering

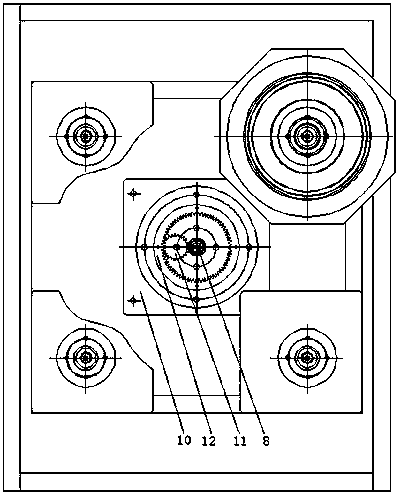

The invention discloses an aluminum foil packaging machine. The aluminum foil packaging machine comprises a machine frame (1). The machine frame (1) is provided with a packaging mechanism and a labeling mechanism. The packaging mechanism comprises a main scroll (2), a tensioning wheel (3), an auxiliary winding wheel, a feed channel and a feed rotary disc (7). The feed channel is communicated with a long notch (8) of the feed rotary disc (7). The vertical long notch (8) of the feed rotary disc (7) is communicated with a clamping and holding station. The machine frame (1) is provided with a station switch rotary disc (10). The station switch rotary disc (10) is provided with a pipe supporting mechanism (11). The pipe supporting mechanism (11) is provided with an inner supporting mechanism. A pipe jacking mechanism (12) is installed at the packaging station of the machine frame (1). The main scroll (2), the tensioning wheel (3) and the auxiliary winding wheel are vertically arranged. The discharge station of the machine frame (1) is provided with a discharge outlet. According to the aluminum foil packaging machine, the feed process is convenient to implement and efficient, the structure is compact, occupied space is small, convenience, high efficiency and energy conservation are achieved in discharging and unloading processes, and automatic labeling is achieved.

Owner:NINGBO TIMES ALUMINUM FOIL MFG +1

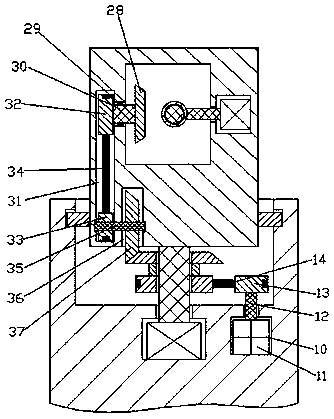

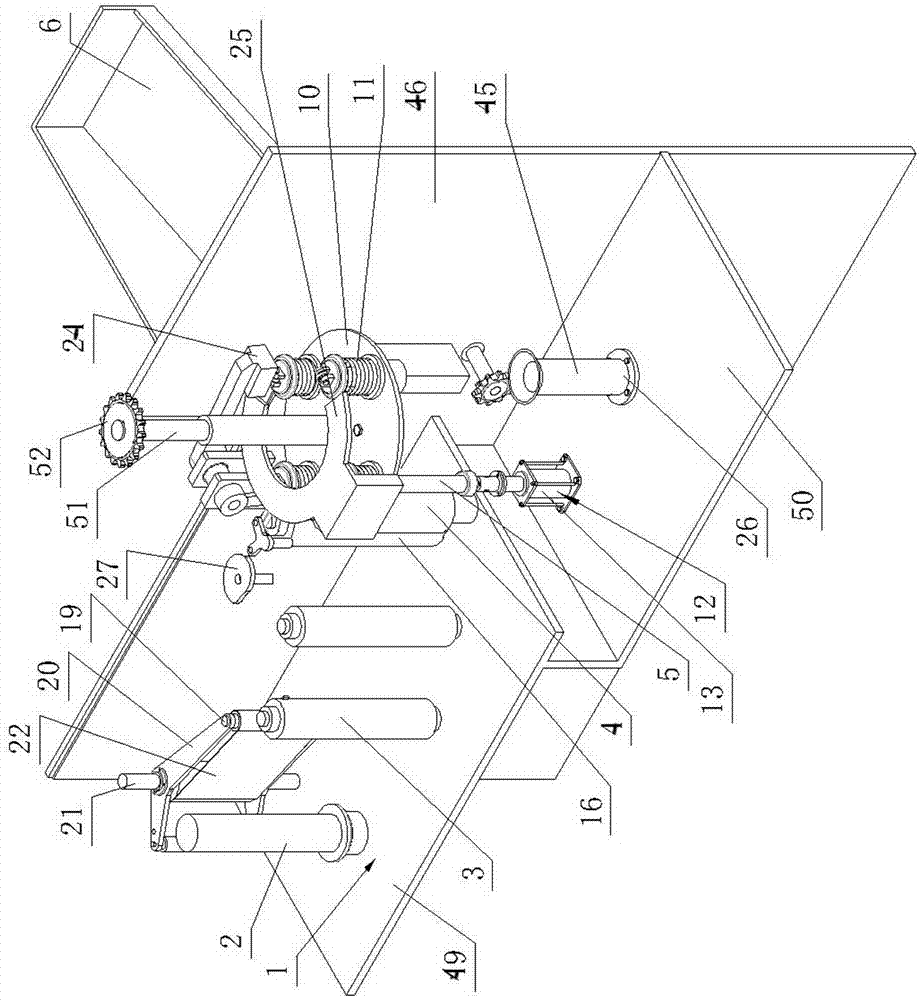

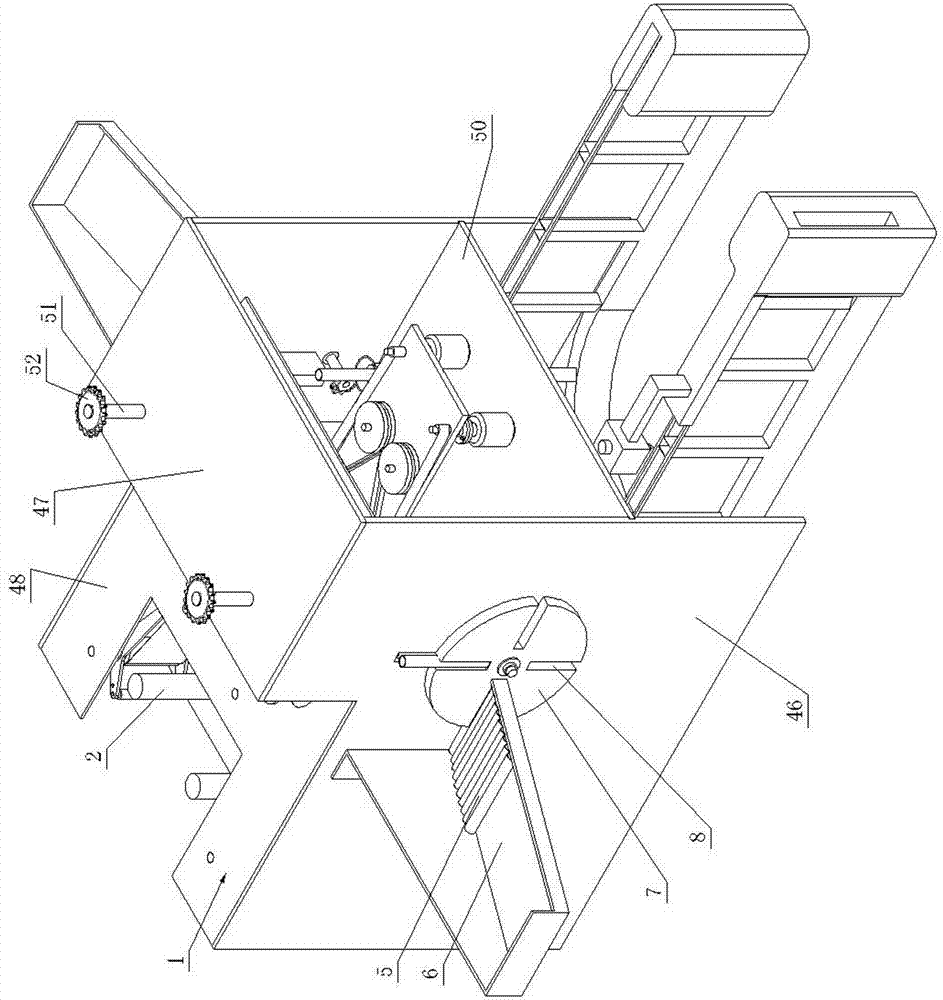

Multistage speed change mechanism of wire harness binding device and speed change method and application of multistage speed change mechanism of wire harness binding device

InactiveCN105836238AGuaranteed intermeshingAdjust the tensionPackaging machinesGear wheelElectric machinery

The invention discloses a multistage speed change mechanism of a wire harness binding device and a speed change method and application of the multistage speed change mechanism of the wire harness binding device. Motor torque transmission, the first-stage speed change and the second-stage speed change are achieved through gear synchronous belt transmission. The outward-expansion angle of a tensioning wheel is achieved through an eccentric bearing, and therefore the tensioning degree of a second-stage synchronous belt is regulated. A rotating body with an equivalent gear structure and an enveloping engagement structure between a gear part of the rotating body and a synchronous belt are adopted, and therefore continuous rotation of the rotating body with a notch and the third-stage speed change of a transmission are achieved. A structure for axially pressing and fixing the rotating body through an inner side guide wheel is achieved through a groove structure in the inner side of the rotating body. Due to the adoption of the structure of the rotating body with the notch, wire harnesses and other packaged objects can be allowed to relatively and continuously rotate relative to the rotating body in the notch. The multistage speed change mechanism can be used for various automatic binding tools or devices used for binding adhesive tape, cotton, cloth, plastic and other materials.

Owner:杭州鼎巅科技有限公司

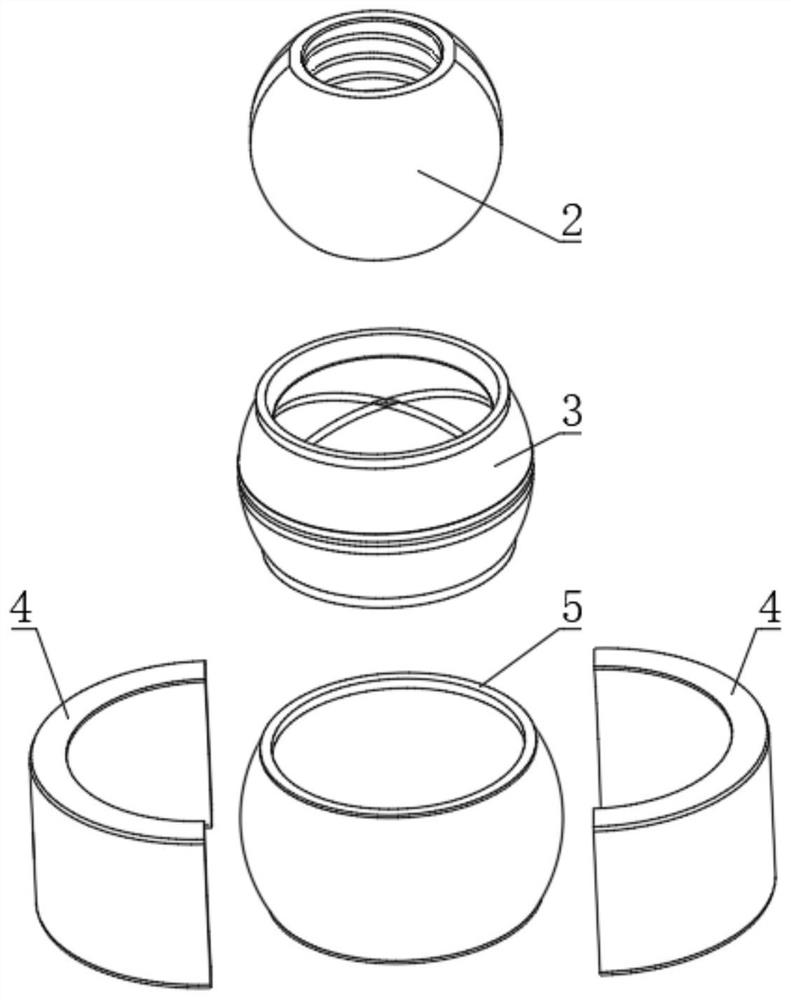

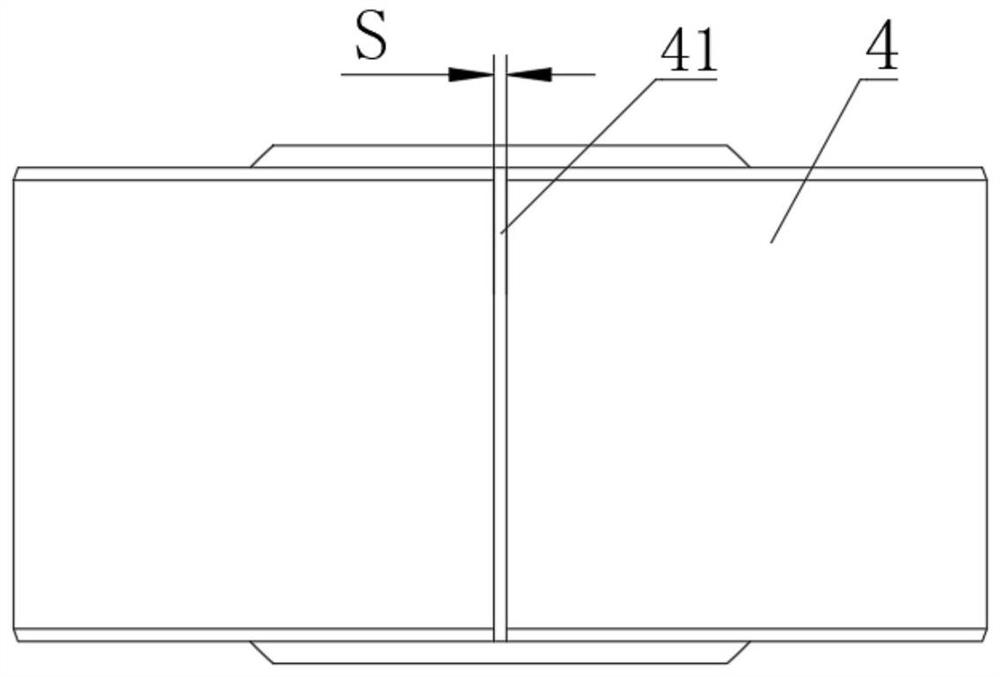

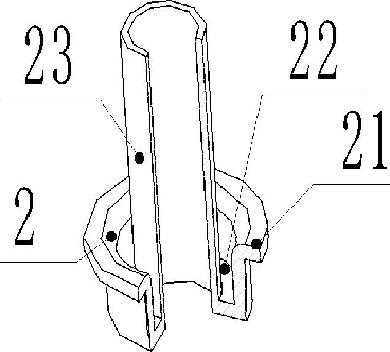

Rigidity-adjustable ball joint and thrust rod assembly

PendingCN112879417AExtended service lifePrevent extrusionPivotal connectionsPivoted suspension armsSuspension (vehicle)Ball joint

The invention discloses a rigidity-adjustable ball joint and thrust rod assembly, and belongs to the technical field of automobile suspension systems. The assembly comprises a thrust rod bracket, a pin shaft, a thrust rod, a ball body, a bearing outer ring and rigidity adjusting sleeves, wherein the ball body is in sliding universal connection with the bearing outer ring; the bearing outer ring is connected with the rigidity adjusting sleeves through an elastic layer; adjusting gaps are formed by the corresponding end faces of the rigidity adjusting sleeves on the two sides; the thrust rod and the rigidity adjusting sleeves are fixedly mounted; and the pin shaft is inserted into a mounting shaft hole and is connected with the thrust rod bracket. Free universal rotation of the thrust rod assembly is achieved through a ball joint, torsion stress of the elastic layer is released, and the elastic layer is only subjected to pressure load; the elastic layer achieves the buffering function of the thrust rod assembly, and the impact load in the force transmission process of the thrust rod is reduced; and the rigidity adjusting sleeves are provided with the adjusting gap, so that rigidity adjustment of the thrust rod assembly is achieved, the reliability of the thrust rod assembly is improved, the service life is prolonged, meanwhile, flexible connection of a suspension system and an axle assembly is achieved, and the comfort of a whole vehicle is improved.

Owner:SINO TRUK JINAN POWER

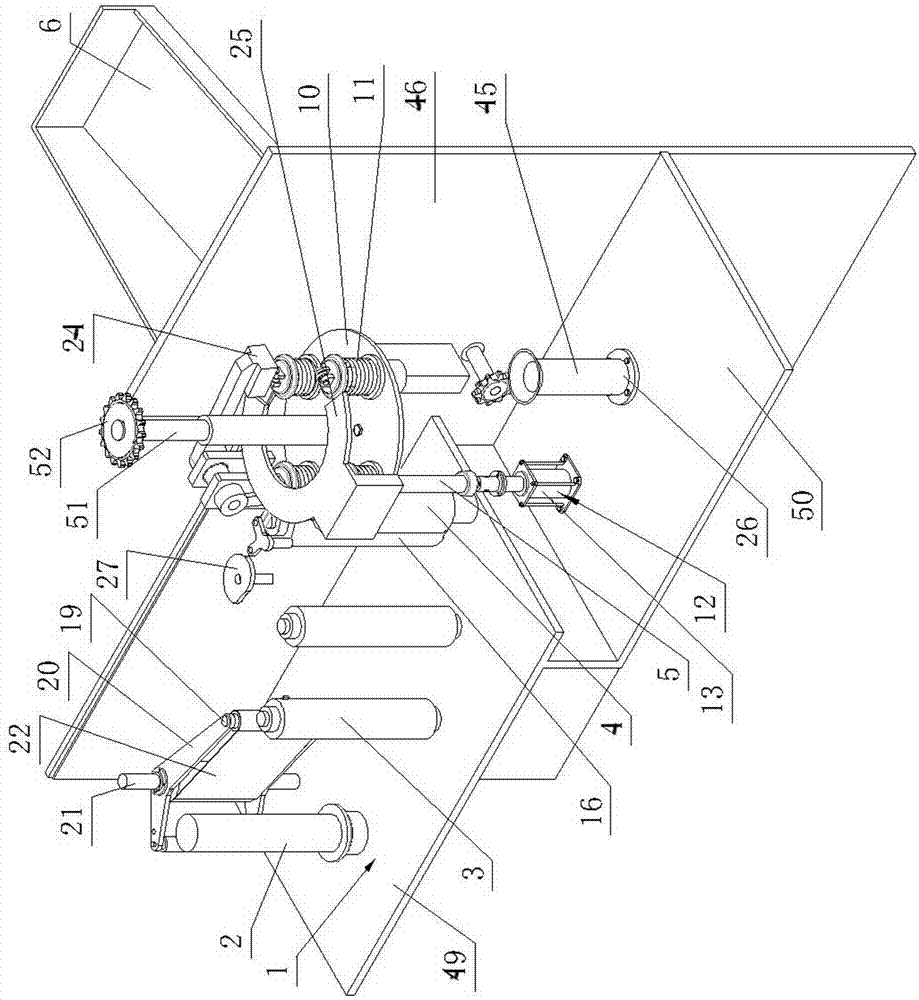

Multifunctional aluminum foil packaging machine

ActiveCN103935798AThe feeding process is convenientHigh accuracy of operation and positioningIndividual articlesPackaging machinesPipe supportAutomation

The invention discloses a multifunctional aluminum foil packaging machine which comprises a machine frame (1). A reeling mechanism and a labeling mechanism are arranged on the machine frame (1). The reeling mechanism comprises a primary reeling shaft (2), tensioning wheels (3), an auxiliary reeling wheel, a feeding channel and a feeding rotary disc (7), the feeding channel is communicated with long notches (8) of the feeding rotary disc (7), the vertical long notches (8) of the feeding rotary disc (7) are communicated with a clamping station, a station switching rotary disc (10) is installed on the machine frame (1), pipe supporting mechanisms (11) are installed on the station switching rotary disc (10), inner supporting structures are installed on the pipe supporting mechanisms (11), a conveying belt is arranged below a discharging opening of the machine frame (1), and a mechanism for folding a box cover is further arranged on the conveying belt. The multifunctional aluminum foil packaging machine is efficient and convenient to use in the feeding process, compact in structure and small in occupied space, discharging and unloading are convenient to achieve and efficient and save energy, and automation labeling and automatic box packaging can be achieved.

Owner:NINGBO TIMES ALUMINUM FOIL MFG +1

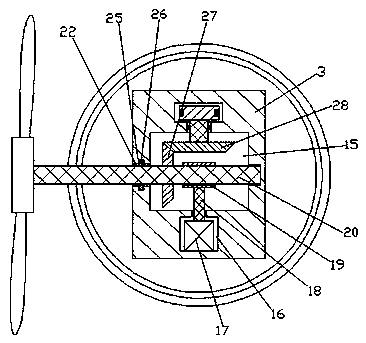

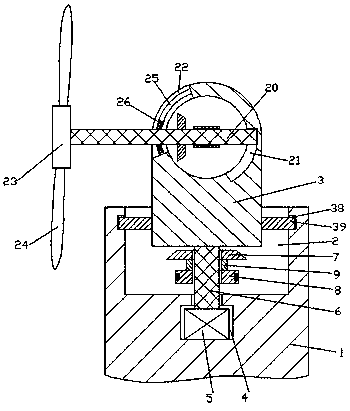

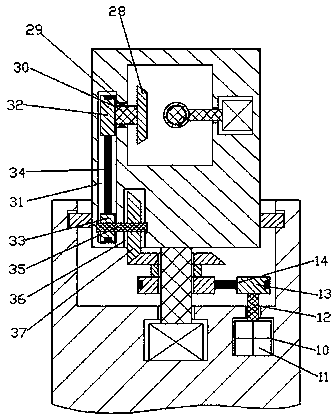

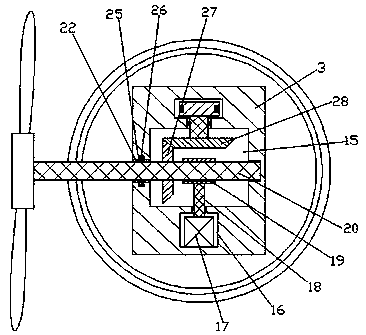

Wind power generation device and using method thereof

InactiveCN109209776AGuaranteed stabilityGuaranteed free spinsWind motor controlWind motor combinationsEngineeringFan blade

The invention discloses a wind power generation device and a using method thereof. The device comprises a fixed supporting rod, a rotating groove with an upward opening is formed in the middle position of the upper end surface of the fixed supporting rod, a rotating block which extends upwards is arranged on the upper side of the inside of the rotating groove, an annular adjusting space is formedin the upper side of the inside of the rotating block, the left end of the rotating shaft penetrates through the swinging hole to extend leftwards and is fixedly connected with a rotating disc, a plurality of fan blades are uniformly distributed at the annular end surface of the rotating disc, and the lower end of the fourth bevel gear penetrates out of a transmission groove and is in meshed transmission connection with a first bevel gear. In the working process, through the multi-angle adjustment in the horizontal direction and the vertical direction, more use requirements of the device can be met, and the device can be adapted to the use environments of different wind directions, the rotating groove is sealed through the rotation of a circular sealing plate and a connecting groove, so that rainwater can be prevented from entering the groove, the safety of the device is protected, the circular sealing plate also plays a role in supporting, and the service life of the device is prolonged.

Owner:QINGTIAN JINCHENG AUTO ACCESSORIES CO LTD

Paper tube conveying mechanism of aluminum foil rewinding machine

The invention discloses a paper tube conveying mechanism of an aluminum foil rewinding machine. The paper tube conveying mechanism of the aluminum foil rewinding machine comprises a machine frame (1), a feed channel (6) and a feed rotary disc. The feed rotary disc is provided with a radial long notch. The tail end of the feed channel (6) is communicated with a horizontal long notch in the feed rotary disc. A vertical long notch in the uppermost position of the feed rotary disc is communicated with the clamping and holding station. The machine frame (1) is provided with a station switch rotary disc (10). The station switch rotary disc (10) is provided with a pipe supporting mechanism (11). The lower end of the pipe supporting mechanism (11) is provided with an inner supporting structure in a rotatable mode. The inner supporting mechanism can extend into an opening in the upper end of a paper tube (5) and tensions the paper tube (5). The paper tube conveying mechanism not only can automatically feed multiple paper tubes (5) in batches, but also can accurately convey the paper tubes (5) to the packaging station so that later packaging can be convenient, and sub rolls after being packaged are automatically separated and discharged.

Owner:NINGBO TIMES ALUMINUM FOIL MFG

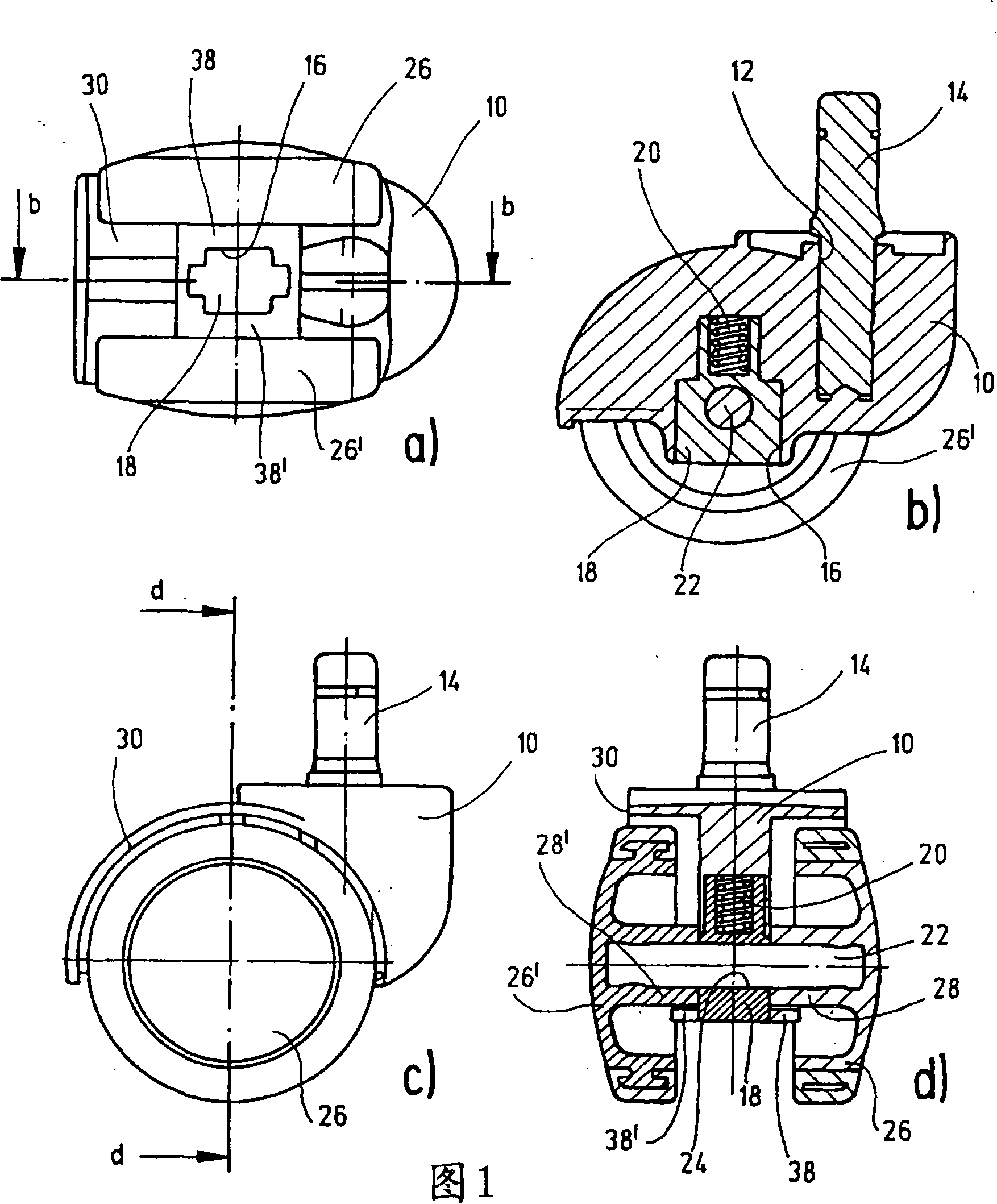

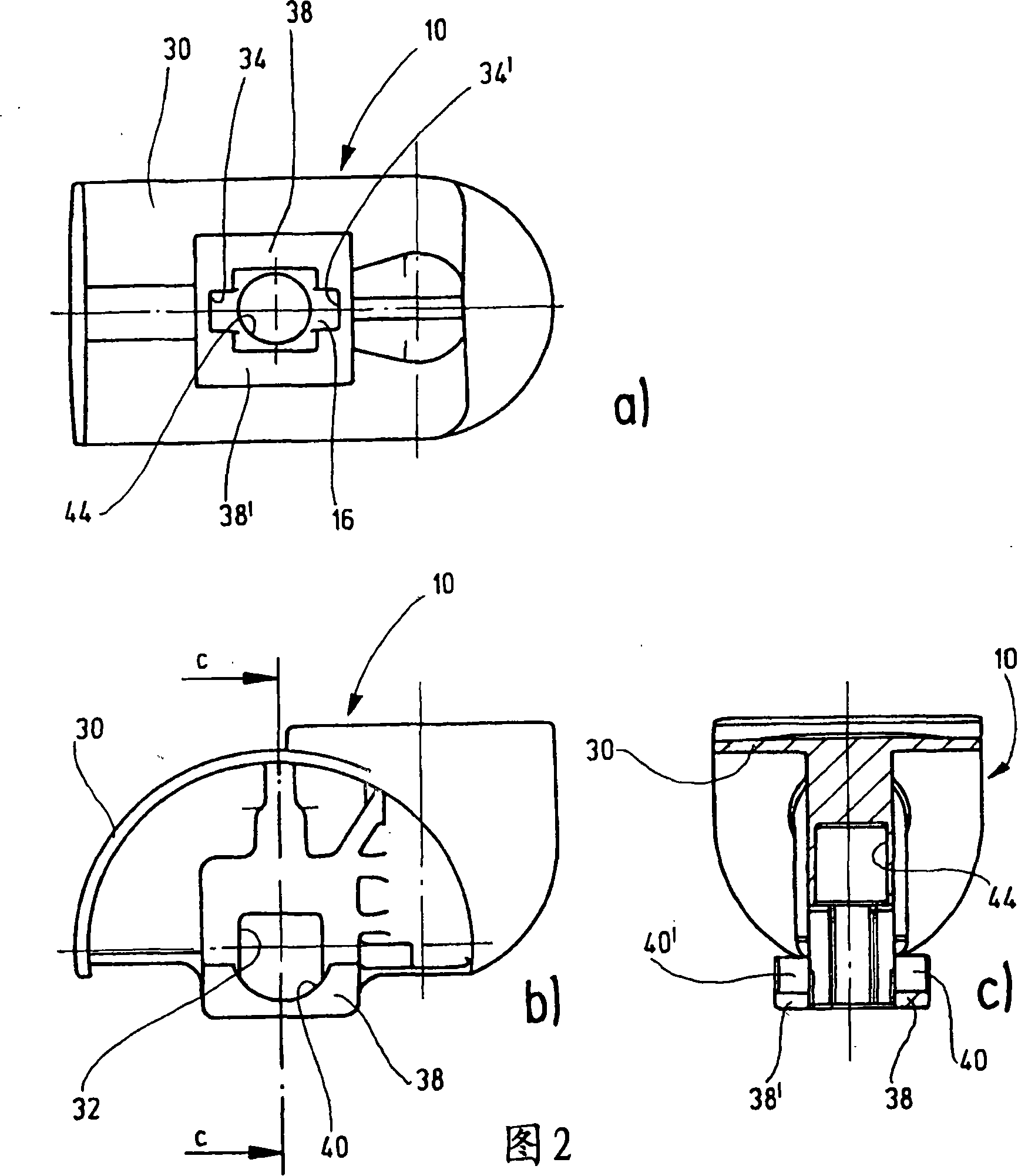

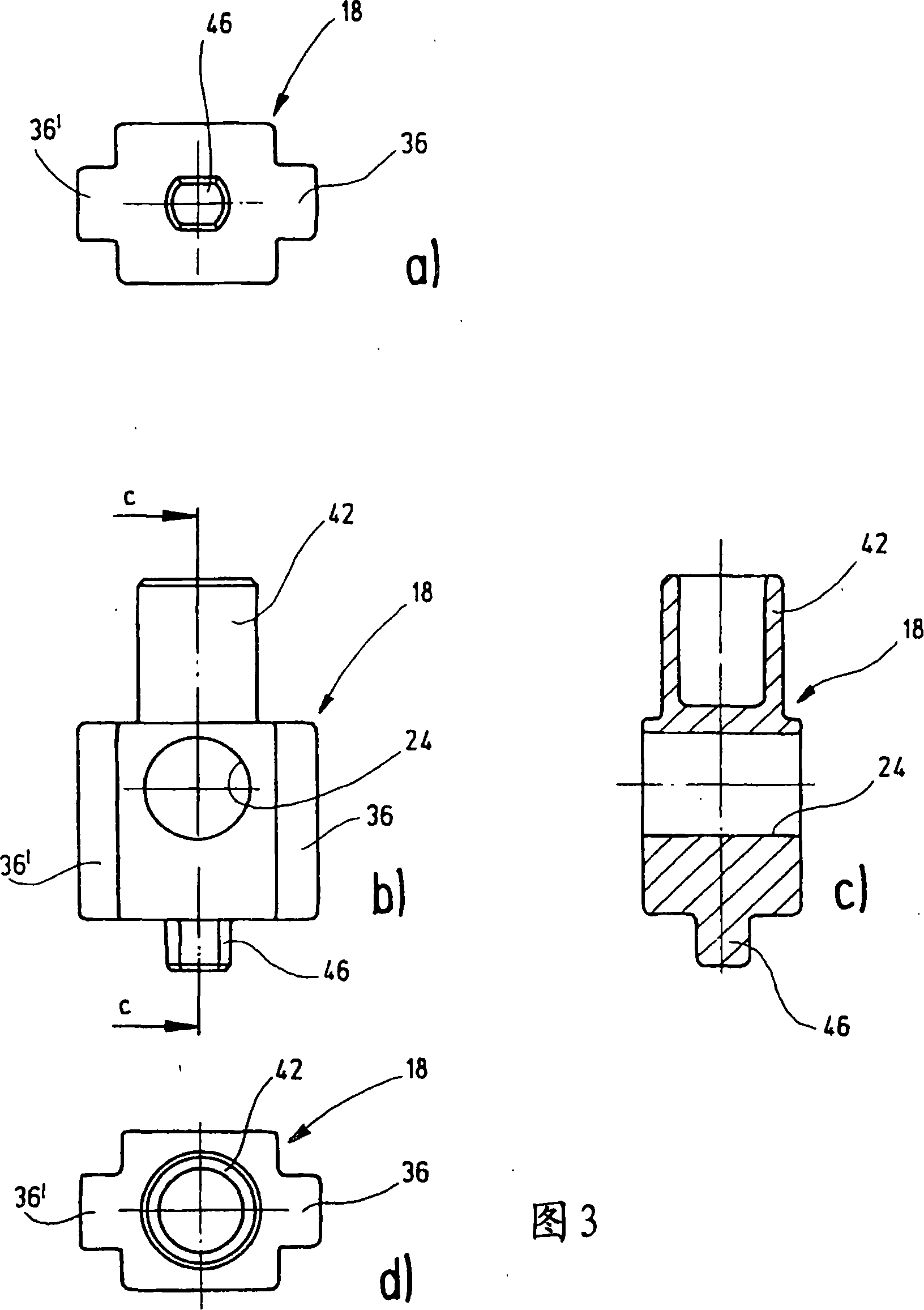

Twin-wheel caster

The castor has a housing (10) with two projections (38, 38`) that are arranged in a lower area of the housing. The projections are provided adjacent to a shaft-shaped slide opening (16) which receives a slide having a through opening to receive a bolt (22). The projections laterally extend from a housing wall over a width of the opening (16) to frictionally support two hubs of wheels (26, 26`) in a braking position. The projections have semi-circular slots provided adjacent to recesses in wall sections. The slide and the housing are made up of polypropylene or polyamide plastic.

Owner:GROSS & FROELICH

Columnar coupling compound sucker rod centralizer

InactiveCN102071884BGood and stable self-fluxingImprove the lubrication effectDrilling rodsDrilling casingsCouplingWorking temperature

Owner:黄锦滨 +1

Wind energy power generation equipment

InactiveCN109139381AGuaranteed stabilityPrevent rainwater from enteringWind motor controlMachines/enginesEngineeringWind direction

The invention discloses wind energy power generation equipment which comprises a fixed supporting rod. A rotating groove with an upward opening is arranged at the middle position of the upper end faceof the fixed supporting rod. A rotating block extending upwards is arranged on the upper side in the rotating groove. An annular adjusting space is arranged on the upper side in the rotating block. The left end of a rotary shaft penetrates a swing hole to extend leftwards and is fixedly connected with a rotary disc. Multiple blades are evenly distributed on the annular end face of the rotary disc. The lower end of a fourth bevel gear penetrates out of a transmission groove and is in transmission connection with a first bevel gear. According to the wind energy power generation equipment, during work, more use requirements of a device can be met through multi-angel adjustment in the horizontal direction and the vertical direction, and the equipment is suitable for the use environment of different wind directions; through the running fit of a round sealing plate and a connecting groove, the rotating groove is sealed, rainwater is prevented from entering the rotating groove, and safety ofthe device is protected; and the round sealing plate also achieves a supporting function, and the service life of the device is prolonged.

Owner:QINGTIAN JINCHENG AUTO ACCESSORIES CO LTD

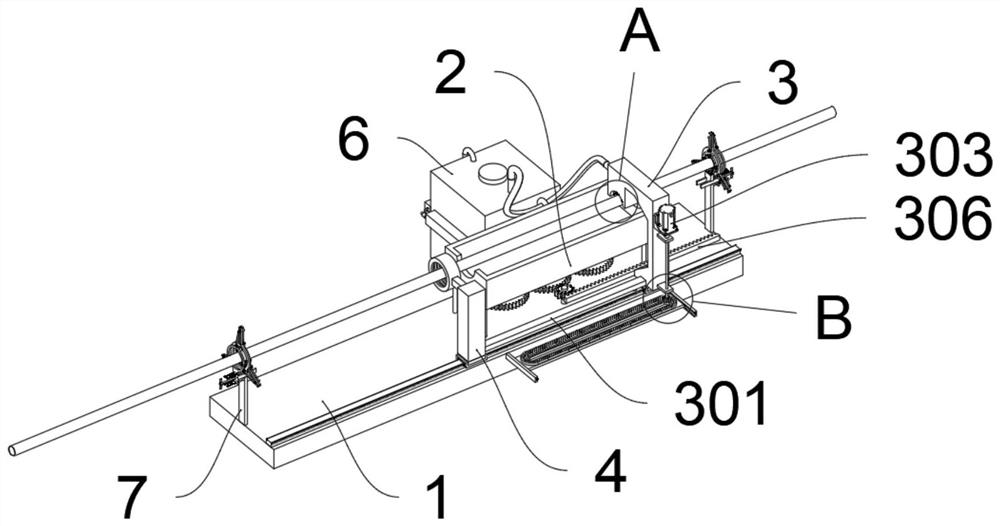

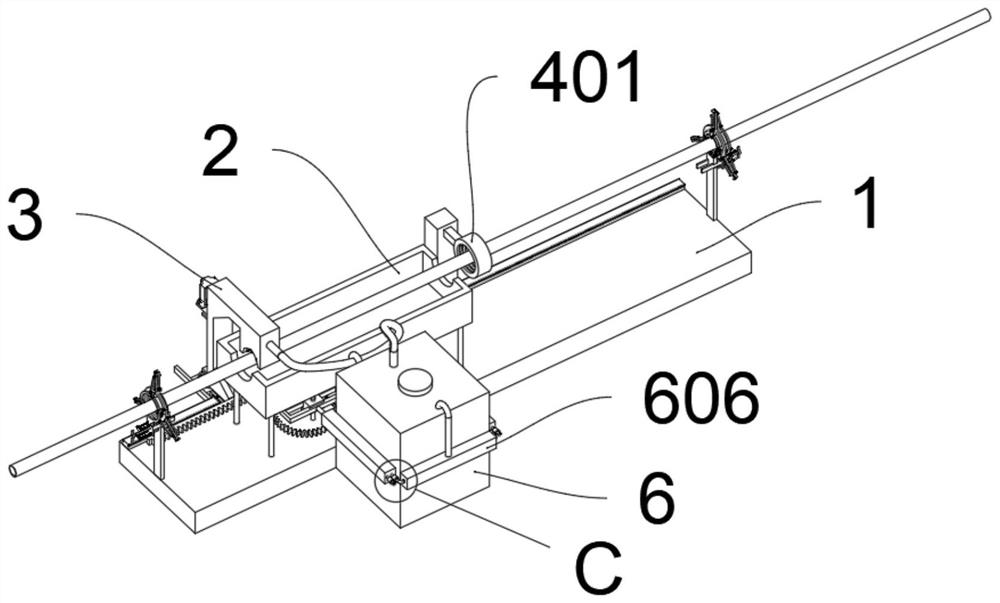

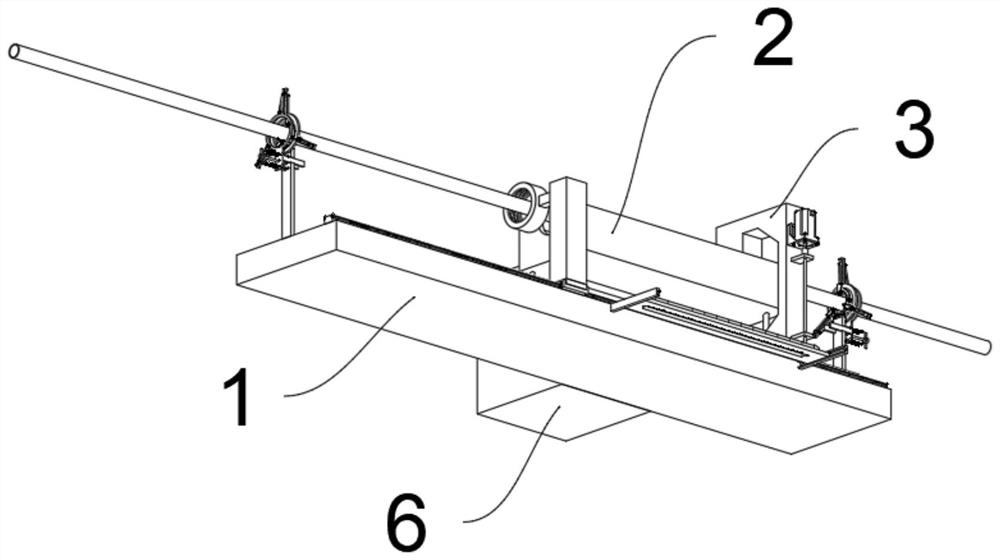

An environmentally friendly reciprocating paint spraying device for pipe fittings used in architectural decoration engineering

ActiveCN112756170BSimultaneous dryingGuaranteed free spinsPretreated surfacesCoatingsPipe fittingArchitectural engineering

The invention discloses an environment-friendly reciprocating paint spraying device for pipe fittings used in architectural decoration engineering, relates to the technical field of architectural decoration engineering, and solves the problem that the currently used paint spraying device does not have the function of fast and automatic reciprocating paint spraying and drying the outer wall of the pipe, and has an automatic effect Insufficient problem. An environmentally friendly reciprocating paint spraying device for pipe fittings used in architectural decoration engineering, including a base; the top of the base is fixed with a recovery channel through a column, and semicircular gaps are opened on both sides of the top of the recovery channel; the front side of the top of the base passes through The guide rail is slidably provided with a movable spray rack and a driven carriage, and a connecting rod is fixedly arranged between the movable spray rack and the driven carriage. The bar provides an automatic reciprocating movement function for the painting device.

Owner:聊城九洲建设集团有限公司

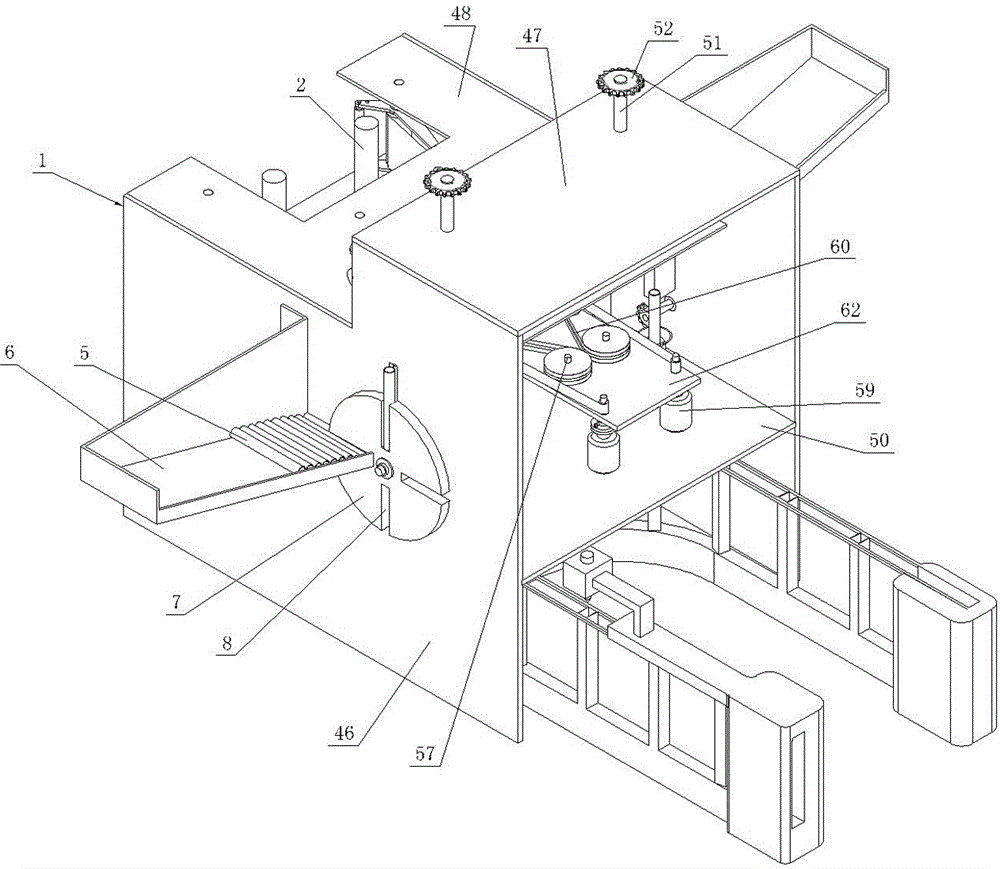

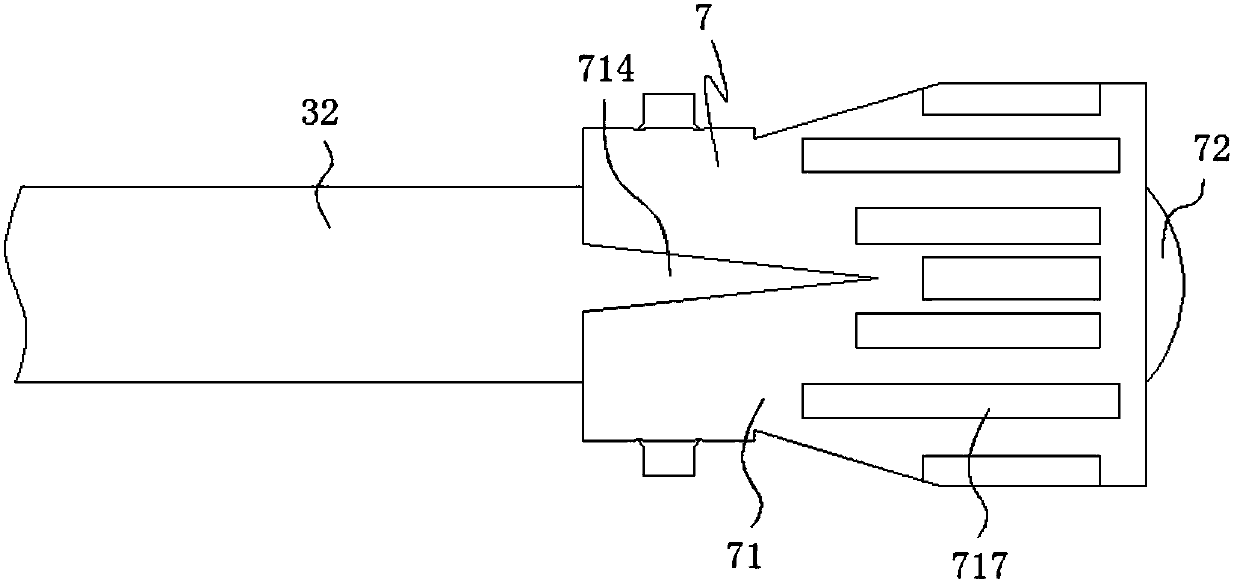

Aluminum foil rewinding machine

ActiveCN103935803AThe feeding process is convenientHigh accuracy of operation and positioningWebs handlingPipe supportEngineering

The invention discloses an aluminum foil rewinding machine. The aluminum foil rewinding machine comprises a machine frame (1). The machine frame (1) is provided with a packaging mechanism. The packaging mechanism comprises a main scroll (2), a tensioning wheel (3), an auxiliary winding wheel (4), a feed channel (6) and a feed rotary disc. The feed channel (6) is communicated with a long notch of the feed rotary disc. The vertical long notch of the feed rotary disc is communicated with a clamping and holding station. The machine frame (1) is provided with a station switch rotary disc (10). The station switch rotary disc (10) is provided with a pipe supporting mechanism (11). The pipe supporting mechanism (11) is provided with an inner supporting mechanism. A pipe jacking mechanism (12) is installed at the packaging station of the machine frame (1). The main scroll (2), the tensioning wheel (3) and the auxiliary winding wheel (4) are vertically arranged. The discharge station (26) of the machine frame (1) is provided with a discharge outlet. According to the aluminum foil rewinding machine, the feed process is convenient to implement and efficient, the structure is compact, occupied space is small, the packaging effect of sub rolls is good, and convenience, high efficiency and energy conservation are achieved in discharging and unloading processes.

Owner:NINGBO TIMES ALUMINUM FOIL MFG

Aluminum foil packaging machine

The invention discloses an aluminum foil packaging machine. The aluminum foil packaging machine comprises a machine frame (1). The machine frame (1) is provided with a packaging mechanism and a labeling mechanism. The packaging mechanism comprises a main scroll (2), a tensioning wheel (3), an auxiliary winding wheel, a feed channel and a feed rotary disc (7). The feed channel is communicated with a long notch (8) of the feed rotary disc (7). The vertical long notch (8) of the feed rotary disc (7) is communicated with a clamping and holding station. The machine frame (1) is provided with a station switch rotary disc (10). The station switch rotary disc (10) is provided with a pipe supporting mechanism (11). The pipe supporting mechanism (11) is provided with an inner supporting mechanism. A pipe jacking mechanism (12) is installed at the packaging station of the machine frame (1). The main scroll (2), the tensioning wheel (3) and the auxiliary winding wheel are vertically arranged. The discharge station of the machine frame (1) is provided with a discharge outlet. According to the aluminum foil packaging machine, the feed process is convenient to implement and efficient, the structure is compact, occupied space is small, convenience, high efficiency and energy conservation are achieved in discharging and unloading processes, and automatic labeling is achieved.

Owner:NINGBO TIMES ALUMINUM FOIL MFG +1

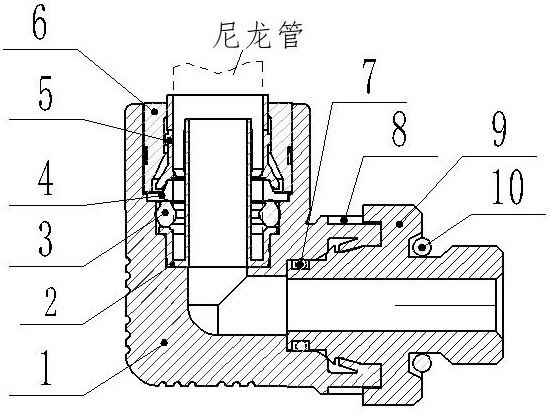

Quick-plug connector with novel combined structure

PendingCN112576833APrevent crushingGuaranteed free spinsCouplingsBranching pipesClassical mechanicsEngineering

The invention provides a quick-plug connector of a novel combined structure. The quick-plug connector comprises a body, a guide rod, a Y-shaped sealing ring, a fixing ring, a clamping ring, a pressingsleeve, and a threaded connector assembly. A hanging table, a stepped hole and a clamping jaw are sequentially arranged inside the structure of the body. A reinforcing rib and an annular boss are sequentially arranged outside the body. The pressing sleeve is matched with the hanging table inside the body in an embedded mode; the clamping ring plays a locking role when a nylon pipe is inserted; the upper end of the fixing ring is pressed by the pressing sleeve; the Y-shaped sealing ring plays a sealing role when the nylon pipe is inserted; the guide rod plays a role in guiding when the nylon pipe is inserted; a dustproof ring is assembled at the boss outside the body; and the threaded connector assembly is assembled at a clamping jaw end and makes contact with the dustproof ring, so that the function of connecting with an installation end is achieved, and the rotating function of the quick-plug connector can be achieved. Compared with the prior art, the quick-plug connector of the novel combined structure has the characteristics of being capable of freely rotating at any angle, good in sealing performance, suitable for different working conditions in different environments and thelike.

Owner:HUBEI OUBO AUTO PARTS

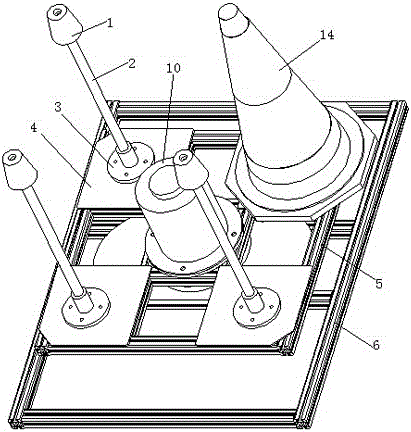

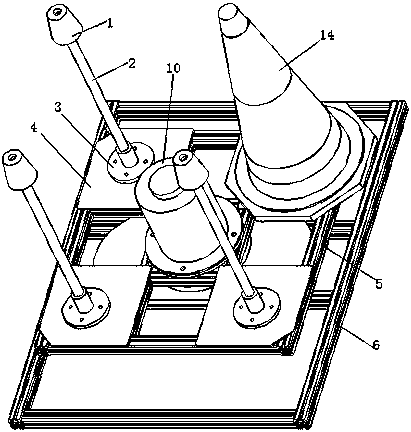

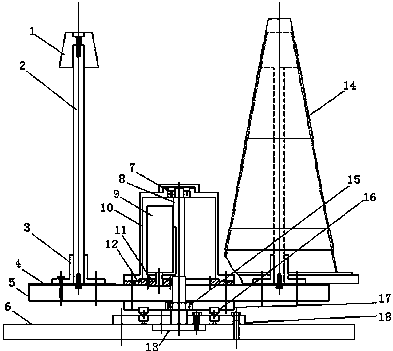

Road cone storage device capable of facilitating mechanical designated fetching

InactiveCN105951628AGuaranteed free spinsReduce frictionTraffic signalsRoad signsRadial stressEngineering

The invention relates to a road cone storage device capable of facilitating mechanical designated fetching. The road cone storage device comprises a fixed base. A fixed shaft is perpendicularly fixed to the fixed base and sleeved with a rotating plate. Radial stress bearings are arranged between the fixed shaft and the rotating plate in a matched mode. An axial stress bearing is arranged between the bottom of the rotating plate and the top of the fixed base in a matched mode. A sealing cover and a plurality of road cone storage rods are fixed to the rotating plate. The upper portion of the fixed shaft is located in the sealing cover, and a motor is fixed to the upper portion of the fixed shaft. An external gear is fixed to the output tail end of the motor. An internal gear engaged with the external gear is fixed to the sealing cover. The road cone storage device capable of facilitating mechanical designated fetching has the storage function and the transferring function at the same time and can rotate road cones to the designated positions.

Owner:WUHAN UNIV OF TECH

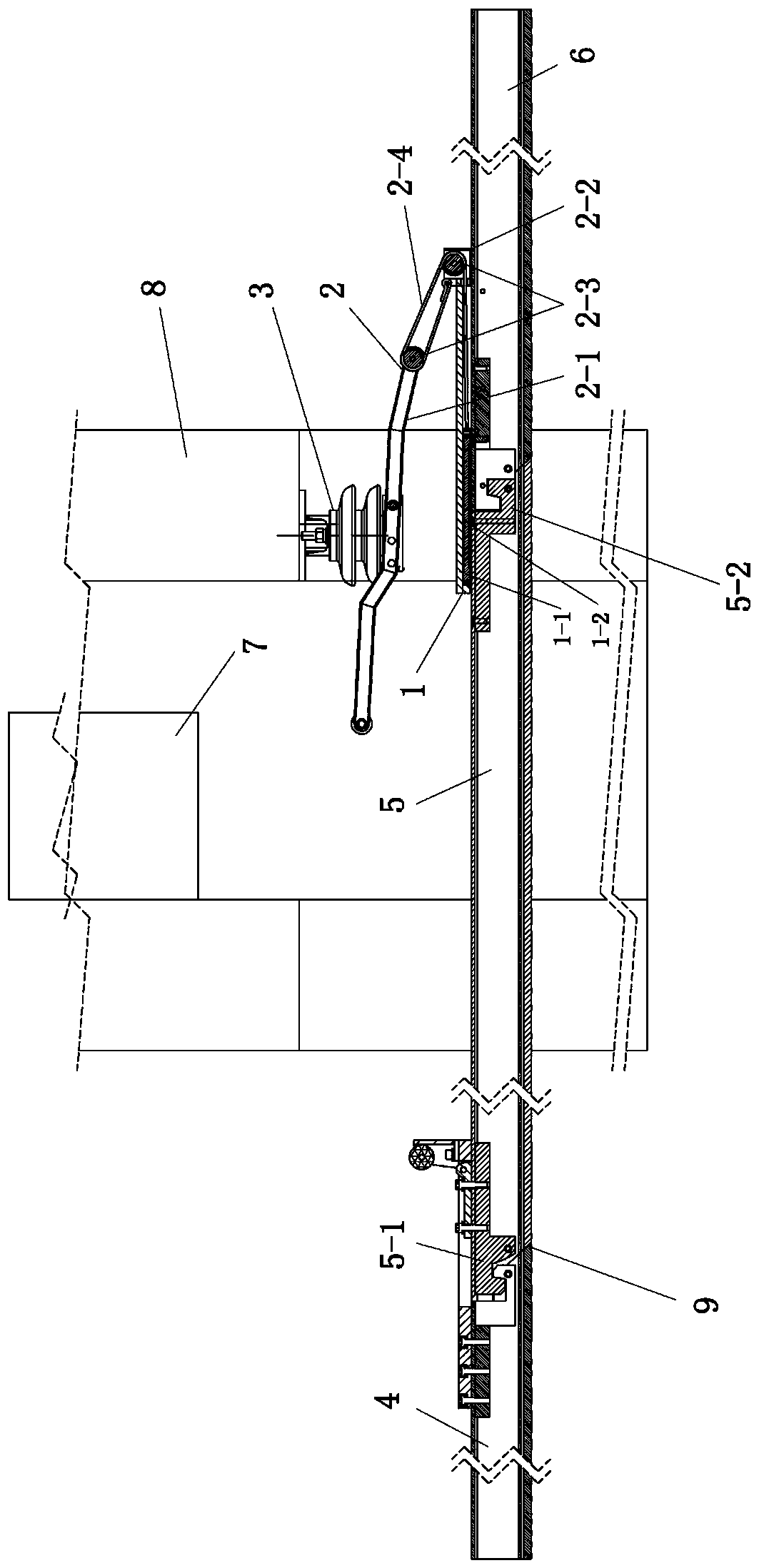

Automatic disconnection device and rail transit rigid contact net

ActiveCN109649221AEnsure personal safetyRealize automatic disconnection functionCoupling device engaging/disengagingElectric connection structural associationsOperation modeRail transit

The invention relates to an automatic disconnection device and a rail transit rigid contact net. The automatic disconnection device comprises a guiding part, a fixing seat part and a transmission part, wherein, the guiding part comprises an outer support seat fixed at the junction of a rear section rigid bus-bar and a guiding block arranged in the outer support seat; rigid bus-bars on both sides are buckled at the bottom end of the guiding block; and the guiding block is connected with the transmission part, and is pulled by the transmission part to slide forwards and backwards at the junctionof adjacent rigid bus-bars to connect or disconnect the two rigid bus-bars. The disconnect device is used at a flood prevention door of a section tunnel through which the rigid contact net of the rail transit passes, and when the flood prevention door needs to start the closing function, physical linkage with the flood prevention door can be realized without manual intervention, so that the rigidcontact net at the flood prevention door is automatically disconnect; the device has a pure mechanical operation mode, and has no electrical interlocking relationship with other professional equipment; and the personal safety of subway operators and the safety of professional equipment are effectively guaranteed.

Owner:长沙勤凯智能科技有限公司

Paper tube conveying mechanism of aluminum foil rewinder

The invention discloses a paper tube conveying mechanism of an aluminum foil rewinding machine. The paper tube conveying mechanism of the aluminum foil rewinding machine comprises a machine frame (1), a feed channel (6) and a feed rotary disc. The feed rotary disc is provided with a radial long notch. The tail end of the feed channel (6) is communicated with a horizontal long notch in the feed rotary disc. A vertical long notch in the uppermost position of the feed rotary disc is communicated with the clamping and holding station. The machine frame (1) is provided with a station switch rotary disc (10). The station switch rotary disc (10) is provided with a pipe supporting mechanism (11). The lower end of the pipe supporting mechanism (11) is provided with an inner supporting structure in a rotatable mode. The inner supporting mechanism can extend into an opening in the upper end of a paper tube (5) and tensions the paper tube (5). The paper tube conveying mechanism not only can automatically feed multiple paper tubes (5) in batches, but also can accurately convey the paper tubes (5) to the packaging station so that later packaging can be convenient, and sub rolls after being packaged are automatically separated and discharged.

Owner:NINGBO TIMES ALUMINUM FOIL MFG

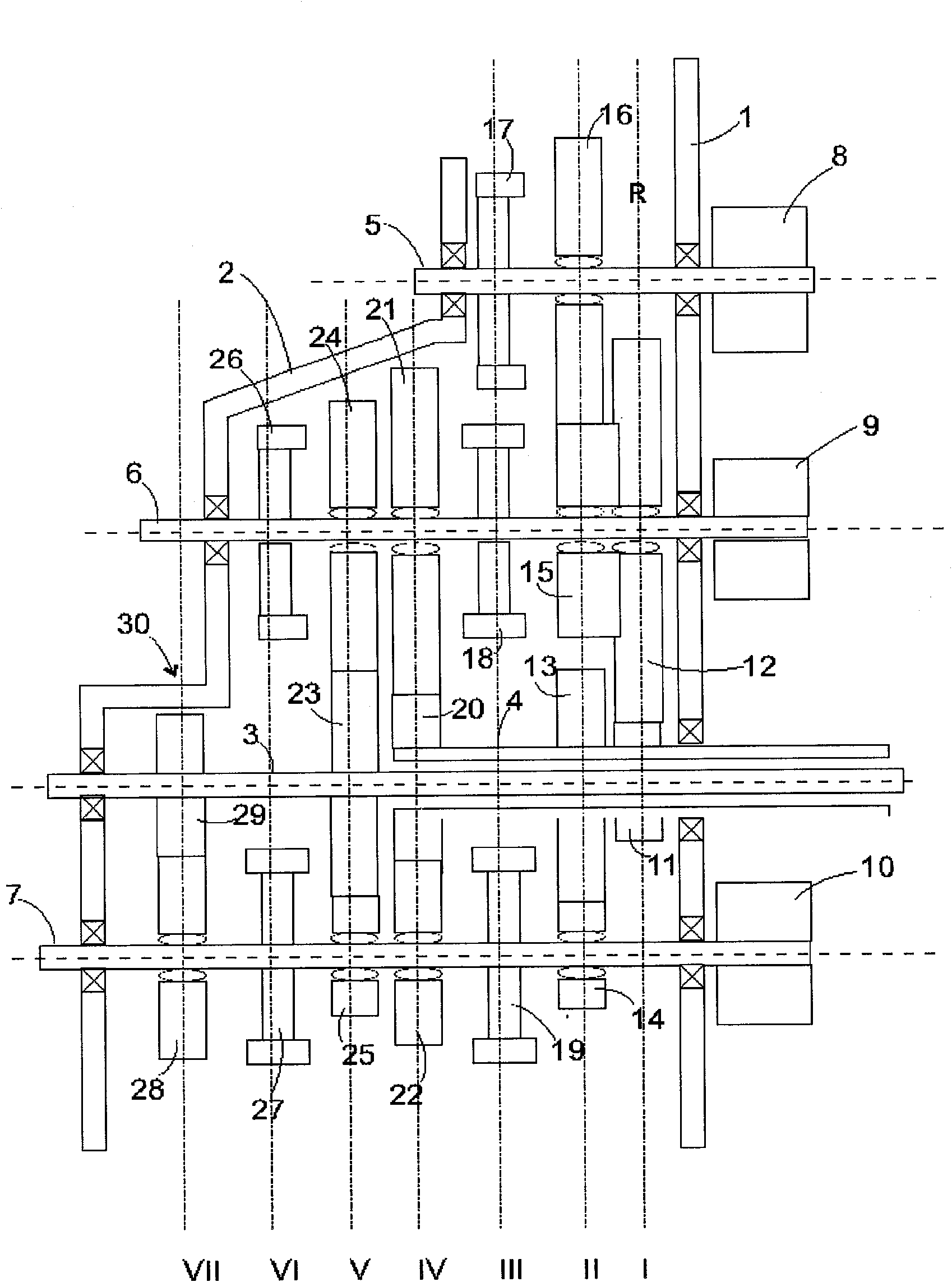

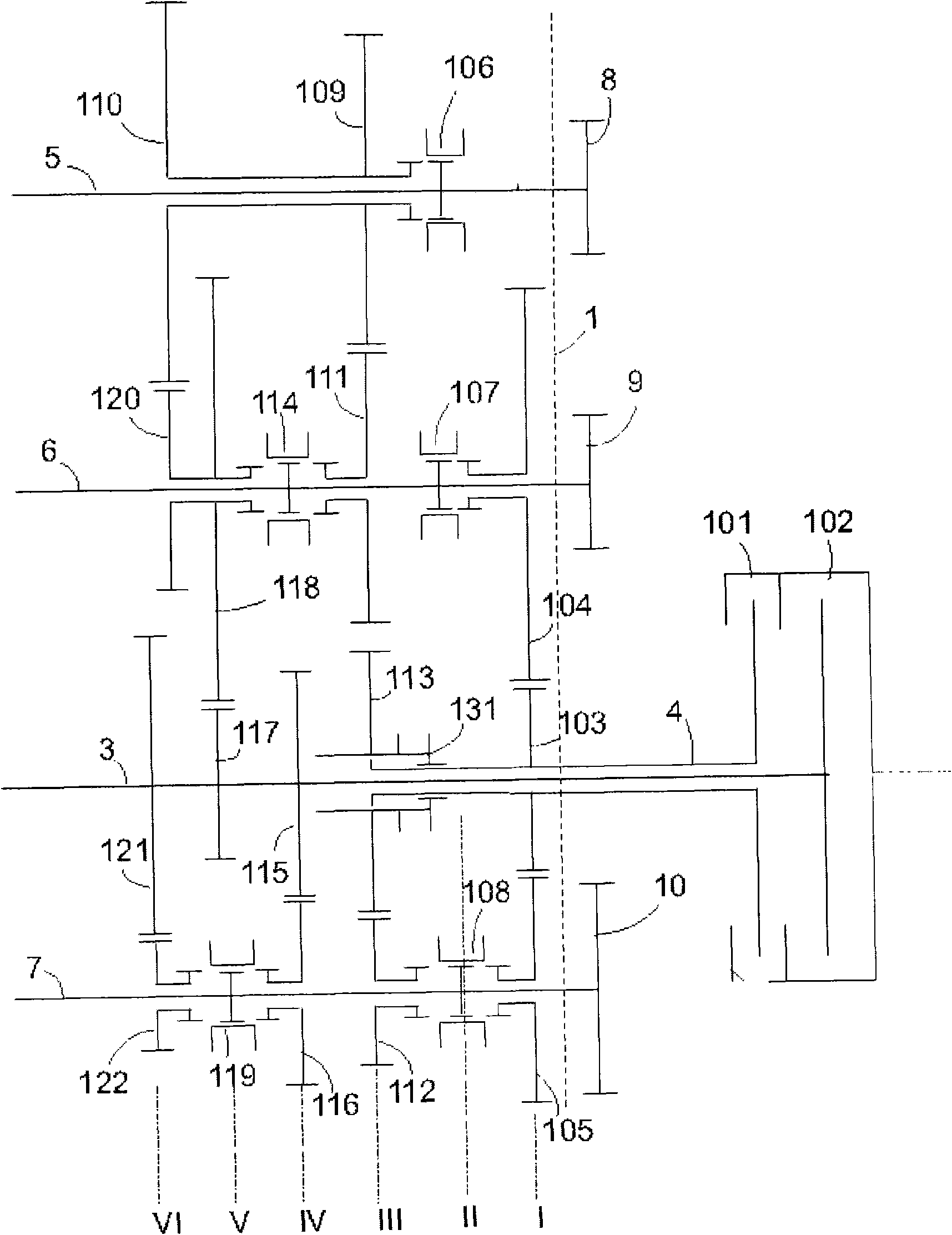

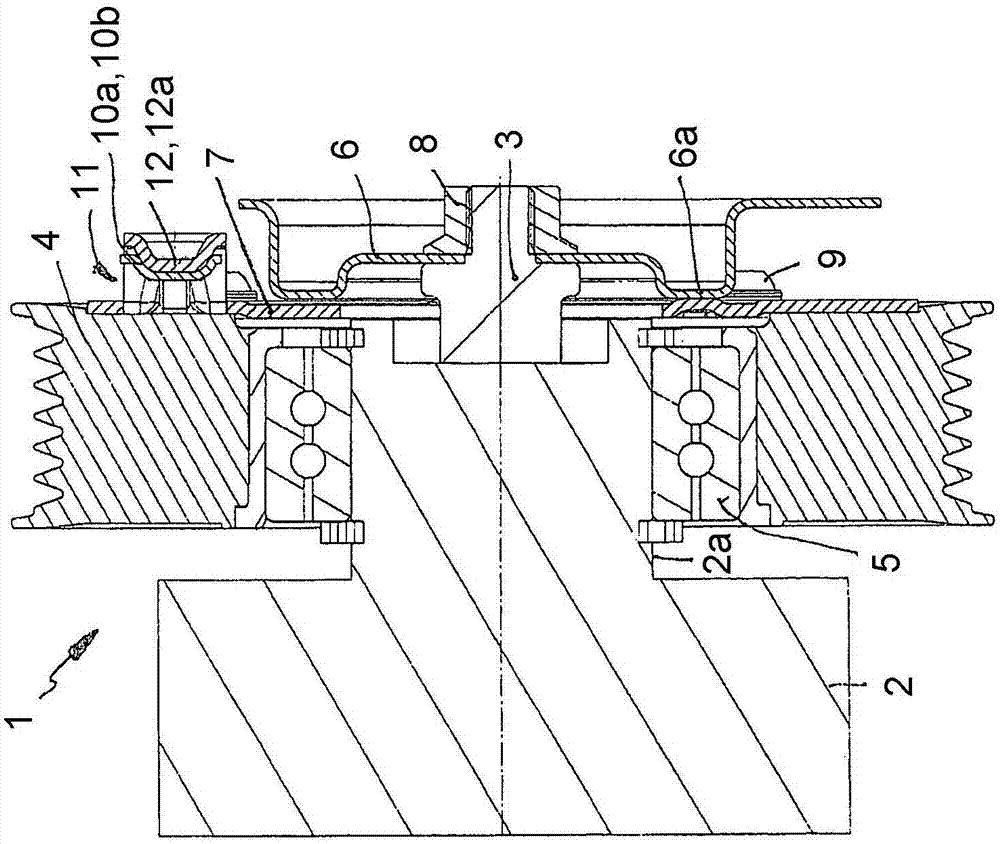

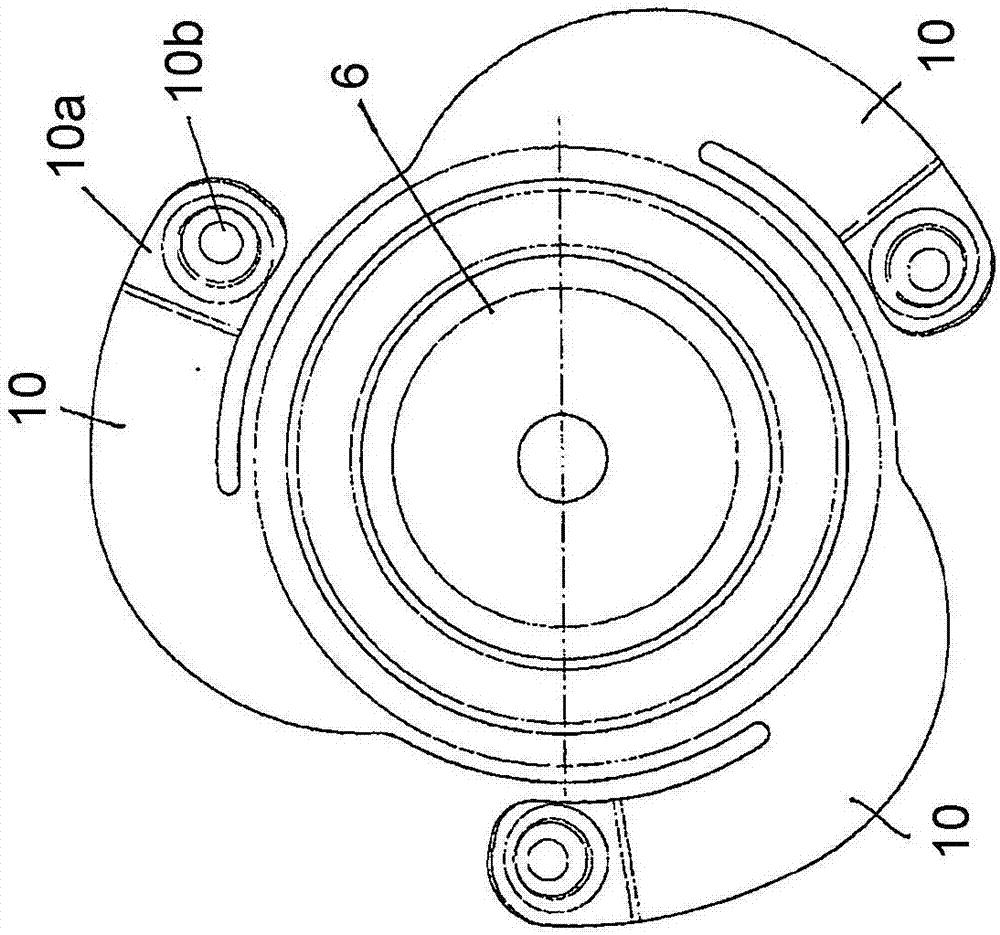

Gearbox for a motor vehicle

InactiveCN101571180ACompact designGuaranteed free spinsToothed gearingsTransmission elementsEngineeringPinion

A gearbox for a motor vehicle comprises coaxial first and second input shafts (3, 4) carrying a plurality of gearwheels (11, 13, 20, 23, 29; 103, 112, 115, 117, 121), and first to third layshafts (5, 6, 7) selectively drivable by said input shafts (3, 4). Each gearwheel (11, 13, 20, 23, 29) of said input shafts (3, 4) meshes with at least one gearwheel (12, 14, 21, 22, 24, 25, 28) of said first or second layshafts (6, 7). The three layshafts (5, 6, 7) carry first to third pinions (8, 9, 10) meshing with a same output gearwheel, and the third layshaft (5) further carries a reverse gearwheel (16) meshing with a gearwheel (15) of said first layshaft (6).

Owner:GM GLOBAL TECH OPERATIONS LLC

A fiber optic vector hydrophone with attitude self-correction function

ActiveCN105387924BEnsure consistencyReduce side pressureSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFiberHydrophone

The invention belongs to the technical field of optical fiber sensing, and in particular relates to a fiber optic vector hydrophone with a posture self-correcting function. The vector hydrophone is special for a towed sonar array, and can realize the posture self-correcting in a roll direction of the vector hydrophone, so as to reach the aim that all vector hydrophone element postures in the array are automatically kept consistent. The invention specifically designs a suspension support system with a bias center of gravity, the system is fixedly connected with the vector hydrophone and can freely rotate. According to a principle of dynamics, the vector hydrophone can automatically keep a state of lowest center of gravity, so as to ensure that all elements of the array are kept in the same posture. The fiber optic vector hydrophone provided by the invention is applicable to the control on the posture of a towed vector array vector hydrophone, and also applicable to the control on the posture of a towed array posture sensor, and can ensure that the posture sensor in the towed array is kept in a horizontal state all the time, so as to improve the measuring accuracy of the posture sensor.

Owner:NAT UNIV OF DEFENSE TECH

Front frame positioner

InactiveCN103962785BGuaranteed stabilityImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesMotor driveEngineering

The invention discloses a front frame position changing machine which comprises a mounting seat. A motor and an L-shaped supporting arm are arranged in the mounting seat, and a through hole is formed in the vertical part of the L-shaped supporting arm. An output shaft of the motor penetrates through the through hole to be connected with the L-shaped supporting arm, and a DC motor is fixedly mounted on the horizontal part of the L-shaped supporting arm. A rotating table is connected to the output end of the DC motor, a plurality of internal threaded grooves are formed in the rotating table, the internal threaded grooves are annular bodies which are formed by a plurality of adjacent through holes, and the internal threaded grooves radiate in the radial direction along the circle center of the rotating table. The front frame position changing machine further comprises pressing plates, the pressing plates are connected with the internal threaded grooves through bolts, and a damping structure is arranged on the through hole. When the motor drives the L-shaped supporting arm to rotate, radial run-out can happen to the output shaft of the motor, so that the L-shaped supporting arm moves up and down. The damping structure is mounted on the through hole, the output end of the motor penetrates through the damping structure so that the radial run-out influence can be removed, the stability of a front frame in the welding process can be further guaranteed, and the welding quality of the front frame is improved.

Owner:CHENGDU HAILINGDA MACHINERY

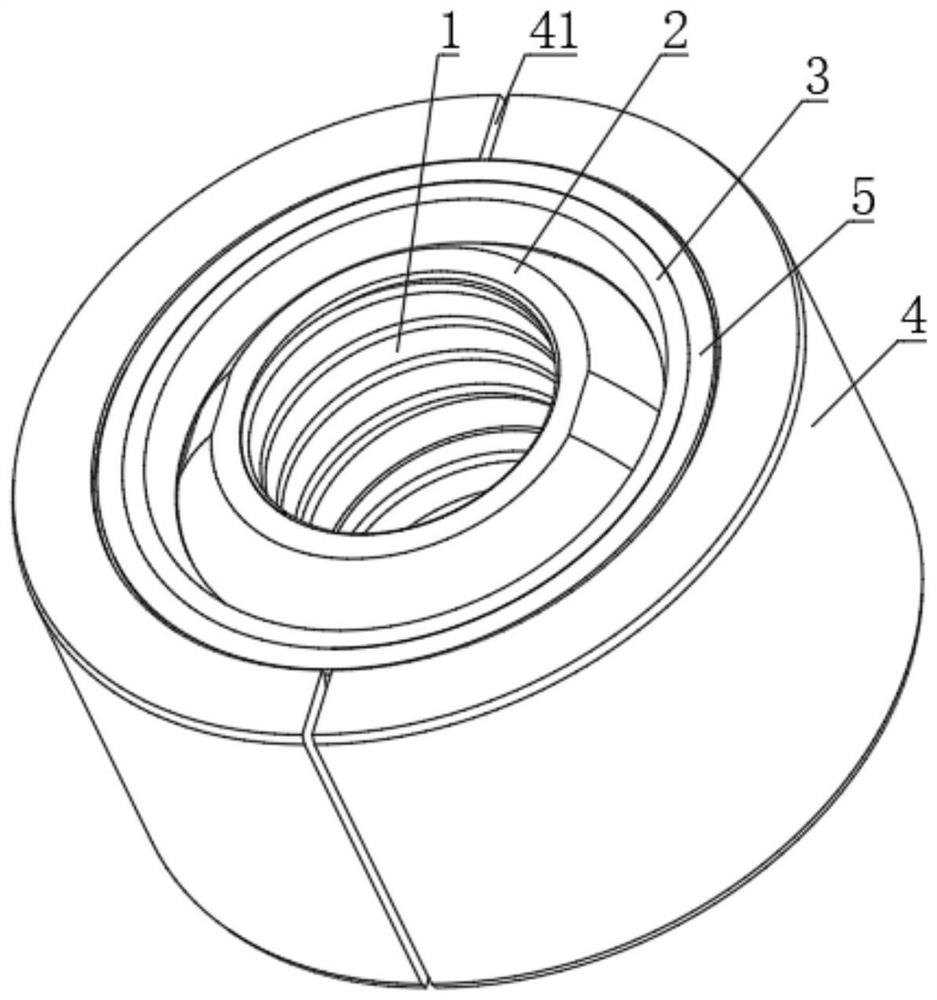

A crucible knife removal device

ActiveCN103434004BGuaranteed free spinsSimple structureStone-like material working toolsCrucibleEngineering

The invention relates to a crucible drawing knife device. The crucible drawing knife device comprises a crucible drawing knife body which is of a hollow cylinder structure, wherein the cylinder wall of the crucible drawing knife body is provided with an upper-down penetrated crucible drawing knife body section groove; the crucible drawing knife body section groove is internally fixedly provided with a sleeve ring, the sleeve ring is internally sleeved with a rotating shaft, the bottom of the rotating shaft is movably connected with an arc-shaped rotating rod, and the top of the rotating shaft is movably connected with a rotating handle; the end part of the arc-shaped rotating rod is provided with a drawing knife head, and the length of the arc-shaped rotating rod is not less than the length of the radius of the crucible drawing knife body which is of a hollow cylinder structure; when the crucible drawing knife device is used, firstly the crucible drawing knife body is inserted into a crucible for one time, a material is longitudinally packed, and then the rotating handle is rotated; the rotating handle drives the rotating shaft to rotate, the rotating shaft drives the arc-shaped rotating rod to rotate, the arc-shaped rotating rod can do a circling motion by surrounding the rotating shaft, the drawing knife head is utilized for cutting off the bottom surface of the packed and sleeved extracted material, the crucible drawing knife body is taken out, and the material is pulled out.

Owner:FIVE STAR NEW MATERIAL TECH CO LTD

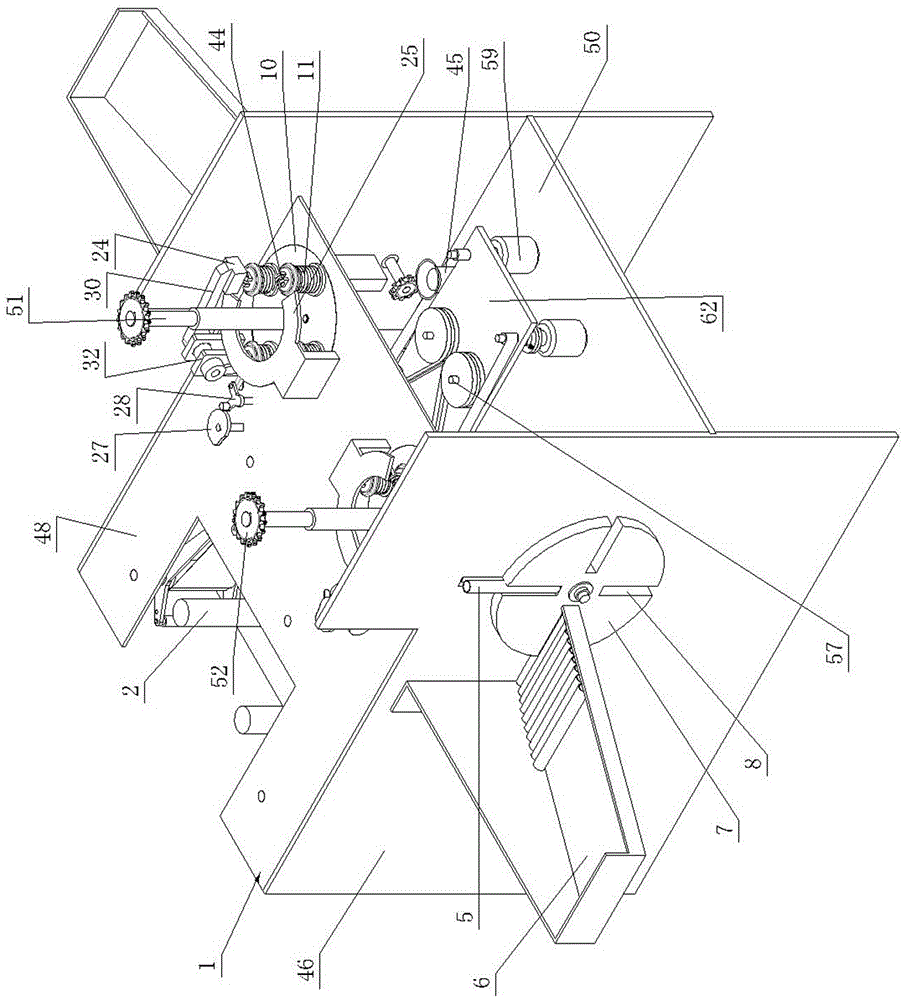

A self-balancing paddy field raking paddle leveling machine

ActiveCN109220014BGuaranteed free spinsConsistent rotary tillage depthSpadesAgricultural machinesWater useRotational axis

The invention discloses a self-balancing paddy field raking and leveling operation machine, which comprises a rotating bracket and a raking machine. Suspended and connected with the tractor, the middle part of the front and rear beams below the rotating bracket is welded with a rotating shaft. The advantages are: the self-balancing paddy field raking machine can automatically adjust the left and right horizontal inclination angle of the raking machine during operation, so that the rotary tillage depth is not affected by the unevenness of the field surface, and can complete the raking, stubble burying and leveling operations in one go, reducing the need for tractors. Rolling of paddy fields. After the operation, the height difference of the field is small, which can improve the utilization rate of water resources, greatly save irrigation water, facilitate intermittent irrigation, achieve precise water use, and the irrigation efficiency can reach 90%. At the same time, the phenomenon of fertilizer loss and defertilization is reduced, and the utilization rate of chemical fertilizers is increased by more than 10%. Fundamentally protect the ecological environment of the entire countryside and control the discharge of harmful substances.

Owner:HUAIHAI INST OF TECH

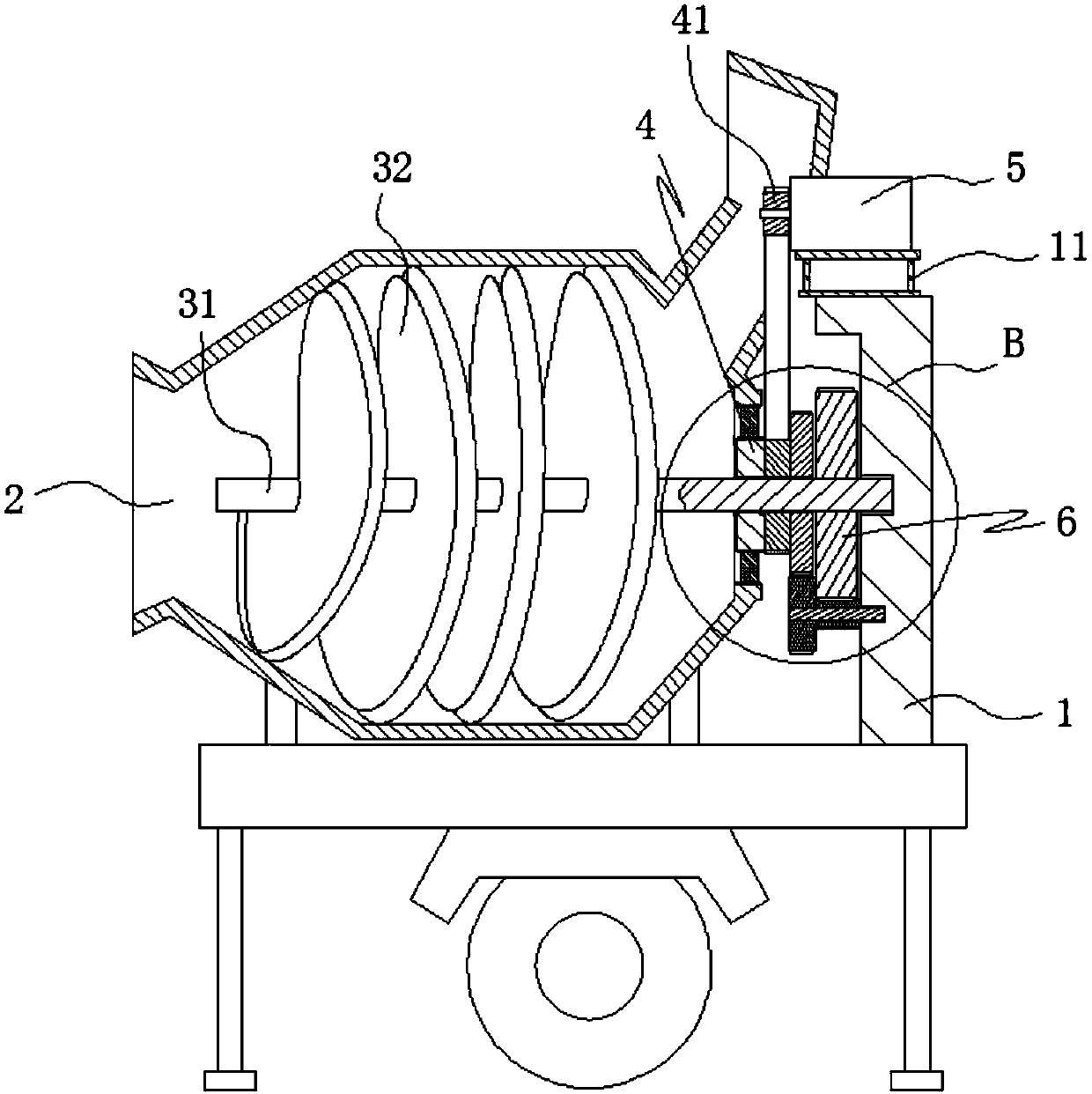

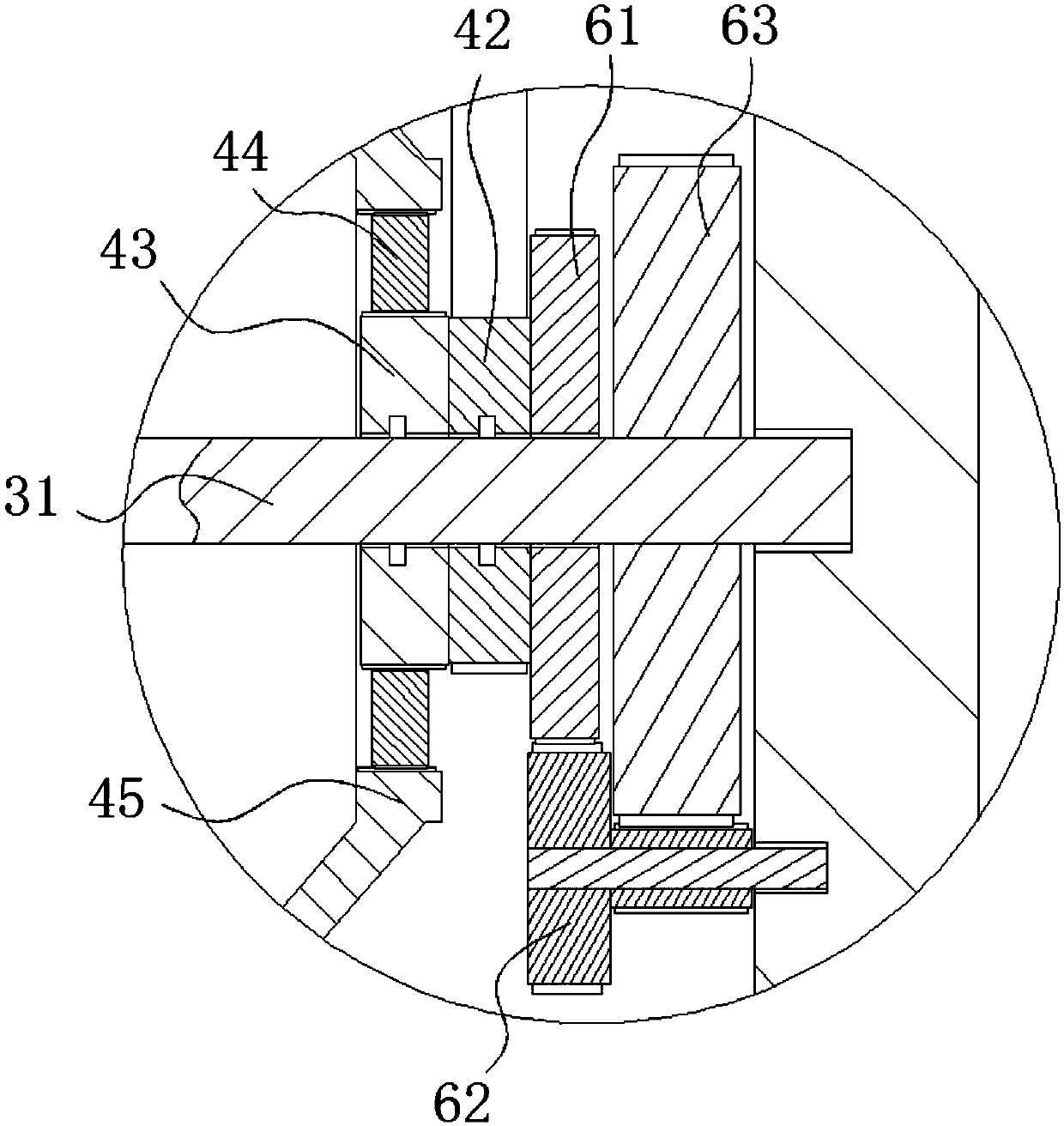

Concrete stirring equipment

ActiveCN107584657AReduce frictionExtended service lifeCement mixing apparatusEngineeringMechanical engineering

The invention discloses concrete stirring equipment. The concrete stirring equipment comprises a rack, a stirring chamber which is rotatably arranged on the rack, a stirring device which is arranged in the stirring chamber and a driving device which is used for simultaneously driving the stirring chamber and the stirring device to rotate in opposite directions, wherein the stirring device comprises a stirring shaft and a spiral stirring blade arranged on the stirring shaft; the driving device comprises a first driving part, a driving part which is used for driving the first driving part to rotate and a second driving part which is in transmission connection with the first driving part. According to the concrete stirring equipment disclosed by the invention, the first driving part is matched with the second driving part, so that the stirring chamber and the stirring shaft rotate in the opposite directions under the driving of the same motor; cement and other materials are mixed sufficiently and the prepared concrete has high quality.

Owner:CHANGDE KEJIAN MACHINERY MFG CO LTD

Aluminum foil rewinder

The invention discloses an aluminum foil rewinding machine. The aluminum foil rewinding machine comprises a machine frame (1). The machine frame (1) is provided with a packaging mechanism. The packaging mechanism comprises a main scroll (2), a tensioning wheel (3), an auxiliary winding wheel (4), a feed channel (6) and a feed rotary disc. The feed channel (6) is communicated with a long notch of the feed rotary disc. The vertical long notch of the feed rotary disc is communicated with a clamping and holding station. The machine frame (1) is provided with a station switch rotary disc (10). The station switch rotary disc (10) is provided with a pipe supporting mechanism (11). The pipe supporting mechanism (11) is provided with an inner supporting mechanism. A pipe jacking mechanism (12) is installed at the packaging station of the machine frame (1). The main scroll (2), the tensioning wheel (3) and the auxiliary winding wheel (4) are vertically arranged. The discharge station (26) of the machine frame (1) is provided with a discharge outlet. According to the aluminum foil rewinding machine, the feed process is convenient to implement and efficient, the structure is compact, occupied space is small, the packaging effect of sub rolls is good, and convenience, high efficiency and energy conservation are achieved in discharging and unloading processes.

Owner:NINGBO TIMES ALUMINUM FOIL MFG

Device for transmitting torque from internal combustion engine to auxiliary unit

InactiveCN107002772ASimple structureIncrease loadSlip couplingGearingExternal combustion engineEngineering

Owner:WINKELMANN POWERTRAIN COMPONENTS GMBH & CO KG

A road cone storage device that facilitates mechanized fixed-point extraction

InactiveCN105951628BGuaranteed free spinsReduce frictionTraffic signalsRoad signsBall bearingEngineering

The invention relates to a road cone storage device for mechanized fixed-point extraction, which comprises a fixed base, on which a fixed shaft is fixed vertically, a rotating disk is set on the fixed shaft, and a radial shaft is arranged between the fixed shaft and the rotating disk. Forced bearing, the axial force bearing is arranged between the bottom of the rotating disc and the top of the fixed base, the sealing cover and several road cone storage rods are fixed on the rotating disc, the upper part of the fixed shaft is located in the sealing cover and the motor is fixed, The output end of the motor is fixed with an external gear, and the sealing cover is fixed with an internal gear meshed with the external gear. The device has both storage and transfer functions, and can rotate the road cone to a fixed position.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com