Paper tube conveying mechanism of aluminum foil rewinding machine

A technology of conveying mechanism and rewinding machine, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problem of difficulty in realizing automatic batch feeding of paper tubes, taking up large space, and separating sub-rolls from machine discharge. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

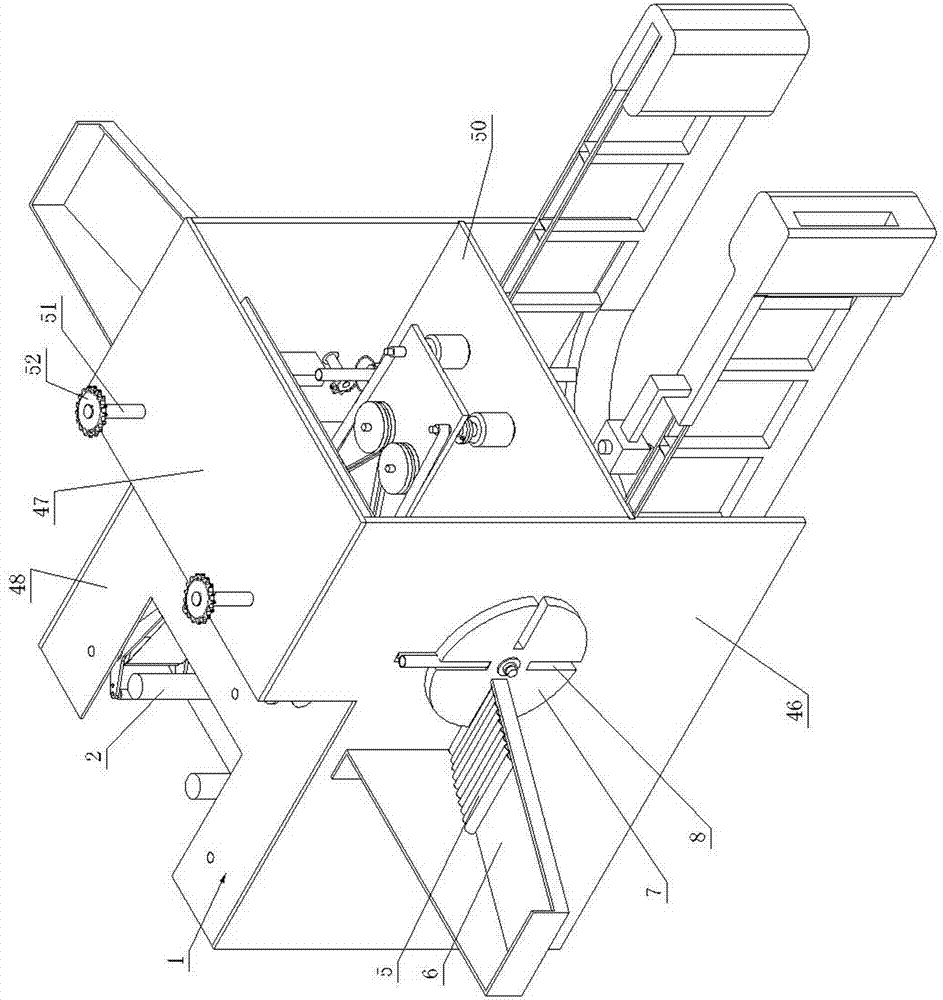

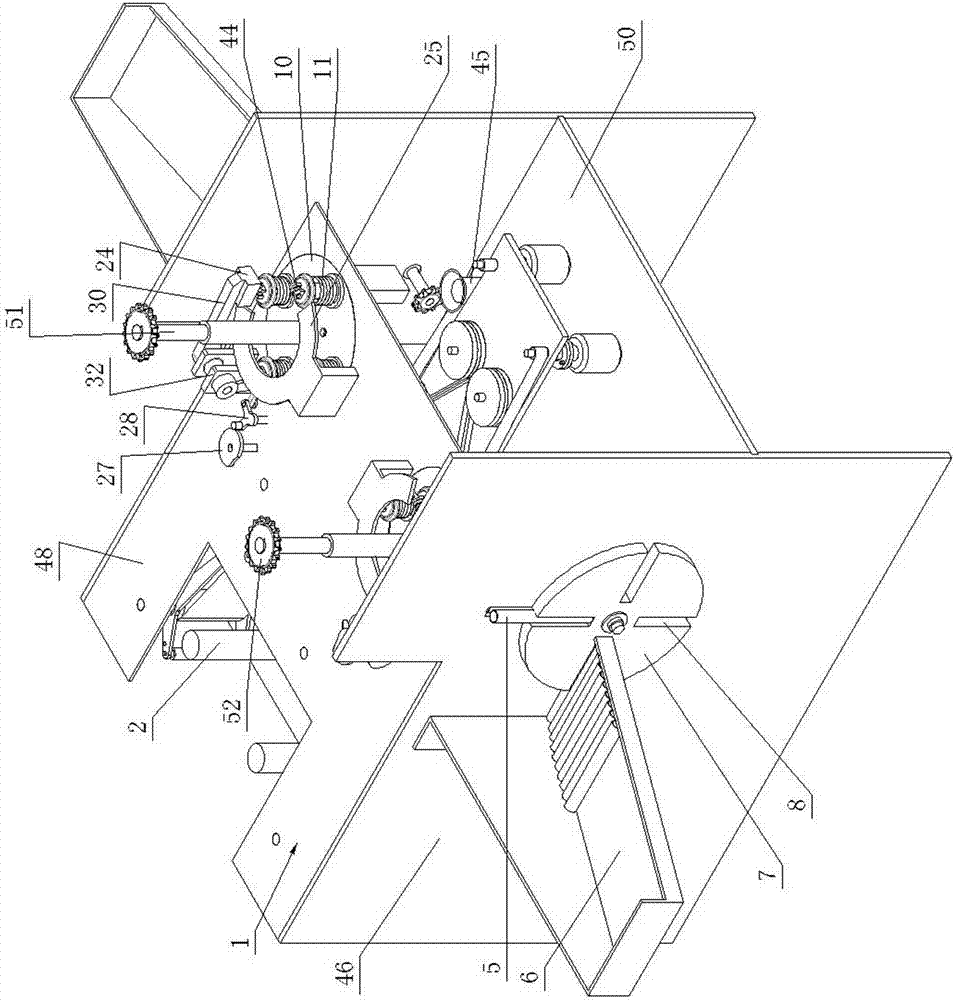

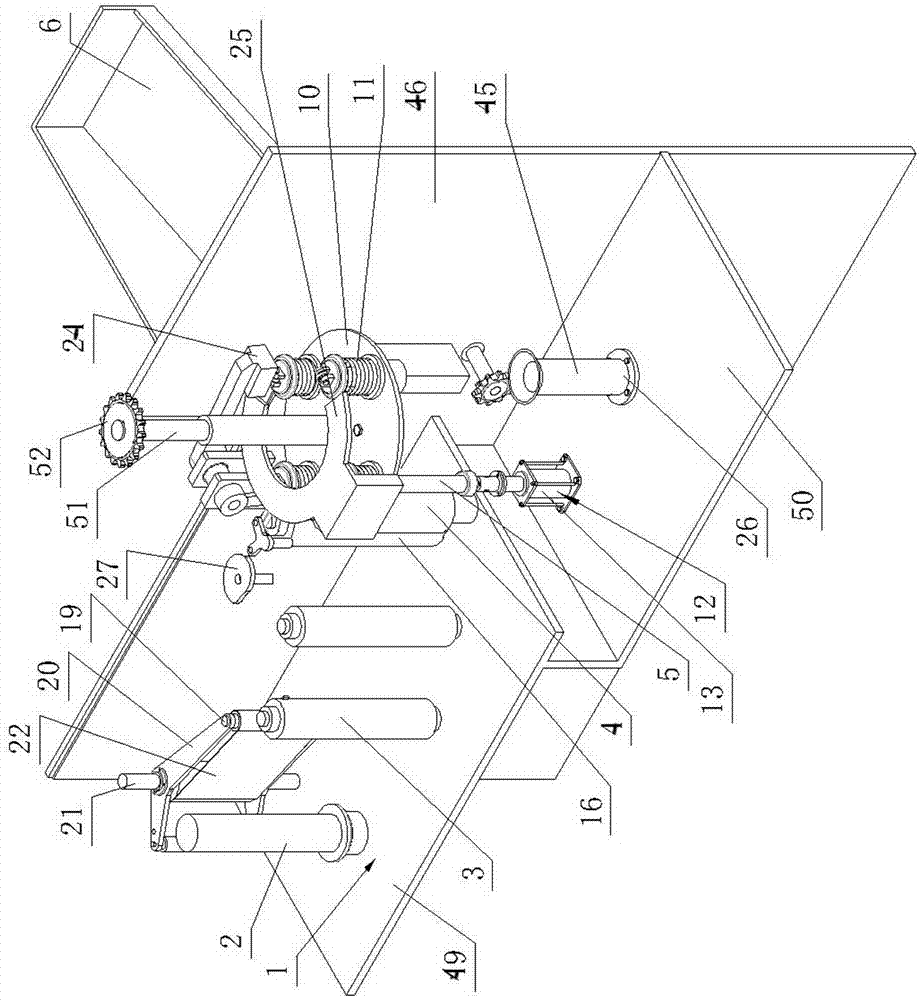

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, the paper tube conveying mechanism of the aluminum foil rewinding machine of the present invention includes a frame 1, and the frame includes two side plates 46, a top plate 47, an upper support plate 48, a middle support plate 49 and a lower support plate 50, Both ends of the top plate 47 and the three support plates are fixed to the two side plates 46 respectively.

[0029] The paper cylinder conveying mechanism of this aluminum foil rewinding machine also includes a feed channel 6 for shelving a plurality of side by side paper cylinders 5 fixed on the side plate 46 of the frame 1 and a side plate 46 which is rotatably fitted on the frame 1. Feed carousel 7 on plate 46 and driven by electric mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com