Cable sealing module

A cable sealing and cable technology, applied in the direction of cable entry sealing device, electrical components, etc., can solve the problems of time-consuming and labor-intensive, and the compression module is large, so as to increase the bonding area, increase the contact area, and facilitate the later stage. maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

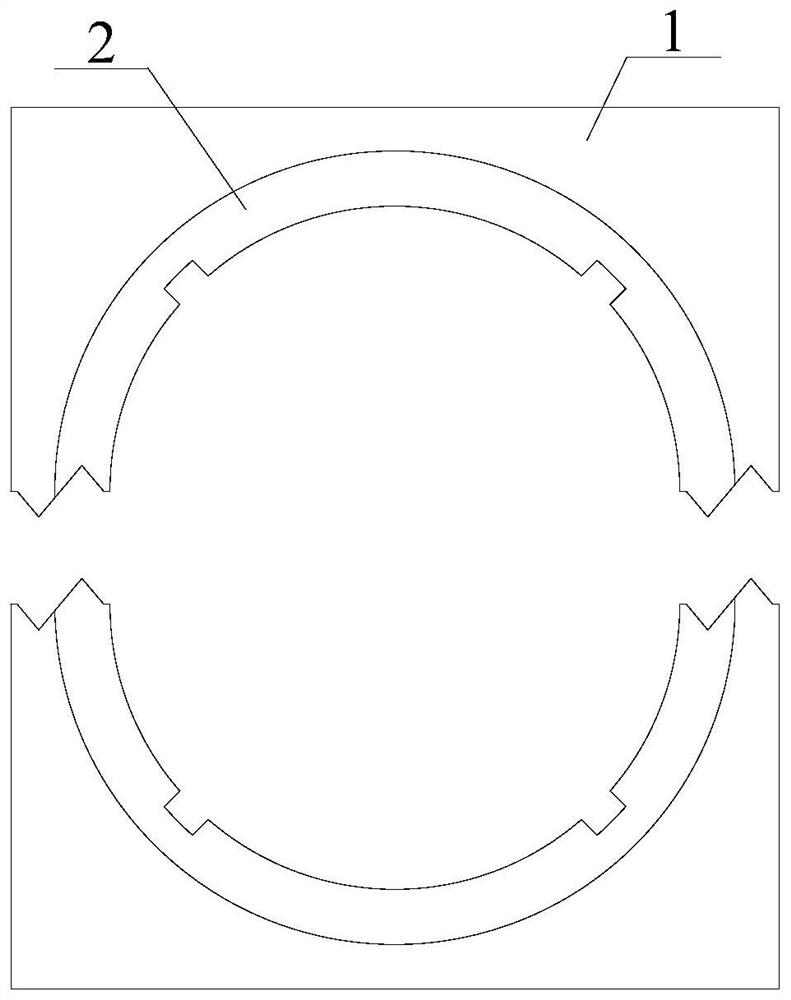

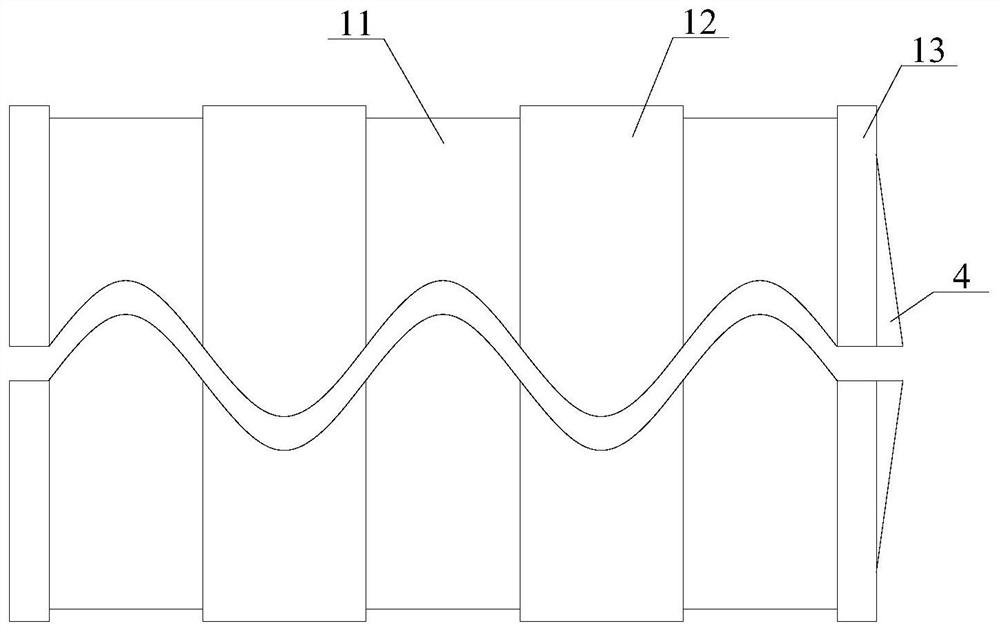

[0025] Embodiment 1: as image 3 As shown, the butt joint of the two assemblies 1 is a sinusoidal curved surface, and both ends of the opening of the arc-shaped groove are provided with folding line sealing structures.

Embodiment 2

[0026] Embodiment 2: as Figure 4 As shown, the butt joint of the two assemblies 1 is a trapezoidal surface, and both ends of the opening of the arc-shaped groove are provided with folding line sealing structures.

Embodiment 3

[0027] Embodiment 3: as Figure 5 As shown, the butt joints of the two assemblies 1 are arc-shaped surfaces, and both ends of the arc-shaped groove opening are provided with folding line sealing structures.

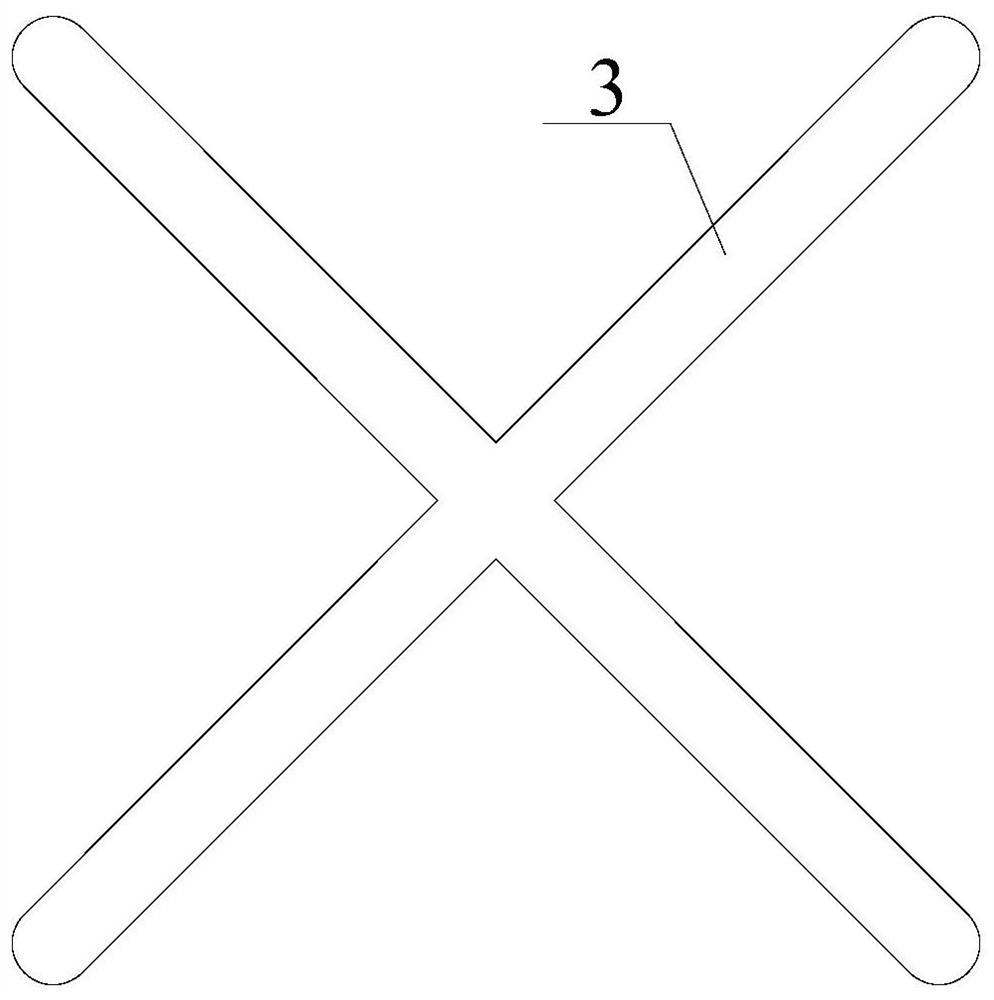

[0028] When the cable sealing module is installed, the assembly 1 is first butted to form a cable accommodation cavity, and then multiple modules are stacked and combined to form a multi-cable assembly, or a single module passes through the wall, and the single module is separated again by the separator 3, which is further convenient. Set of cables with different functions.

[0029] The advantages and benefits of the cable sealing module are:

[0030] 1. The surface meshing method is adopted to increase the bonding area to facilitate the watertightness of the module itself.

[0031] 2. The outer wall of assembly 1 adopts concave-convex design, which reduces the contact area between modules and between modules and the hull to increase the pressure per unit area, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com