Integrated plate spring seat assembly used for heavy truck

A leaf spring seat, integrated technology, used in springs, leaf springs, vehicle springs, etc., can solve the problems of difficult dispersion of frame assembly stress, unfavorable vehicle space layout, cracking fatigue damage, etc., to avoid early fatigue cracking , The effect of saving assembly time and increasing the bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

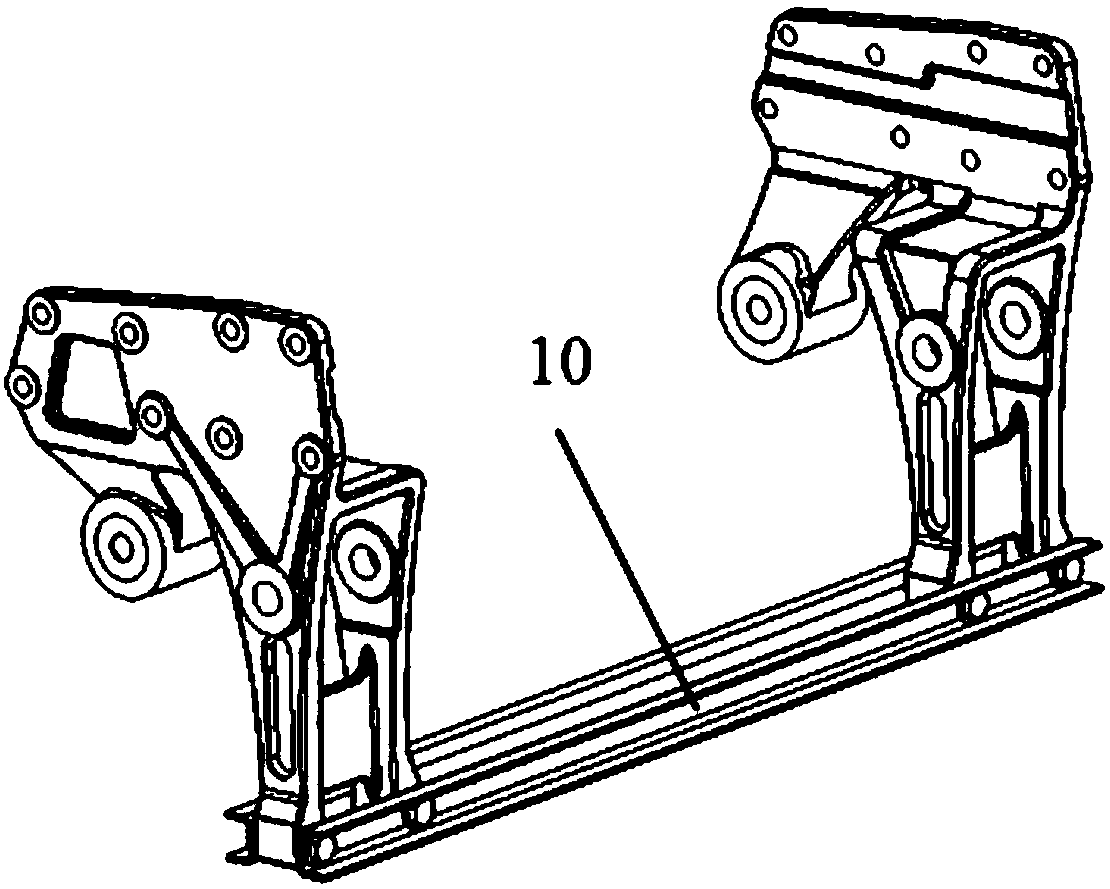

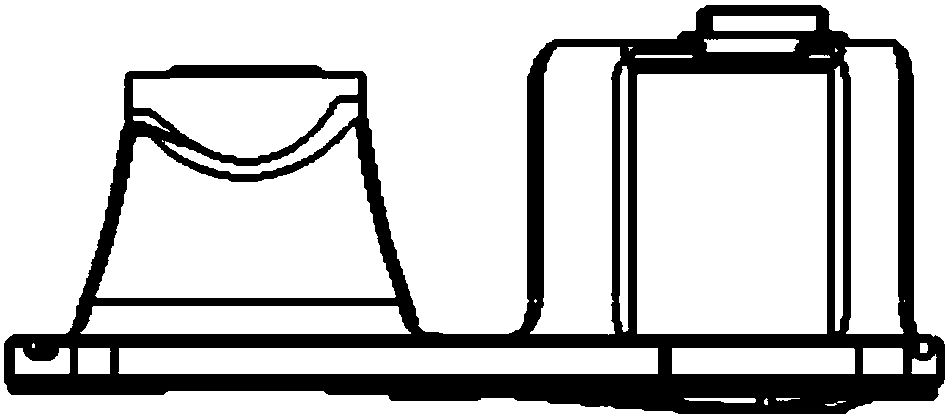

[0027] Such as figure 1 As shown, an integrated leaf spring seat assembly for a heavy truck of the present invention is composed of a left leaf spring seat integrated structure, a right leaf spring seat integrated structure, and an ingot beam. Part of the integrated structure of the left leaf spring seat is used to connect with the rear ear of the maintenance-free leaf spring of the first axle, and the other part is used to connect with the front ear of the non-maintenance-free leaf spring of the second front axle.

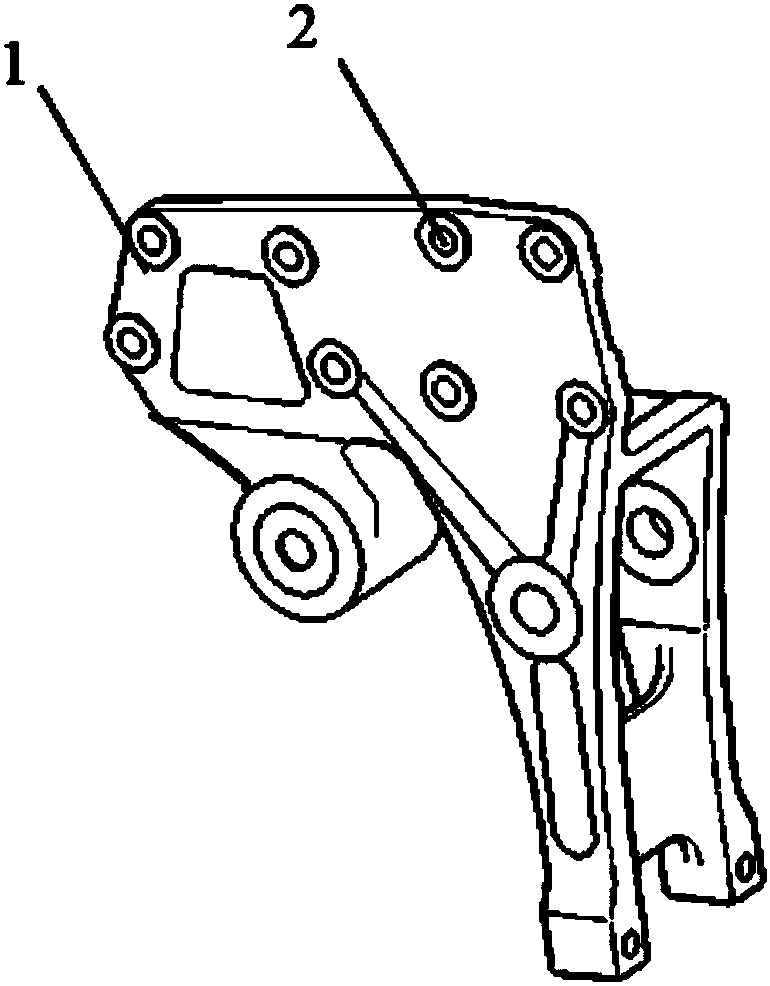

[0028] The integrated structure of the left leaf spring seat includes a vertical plane, an inverted L-shaped structure, a cylinder 3, a bush 4, a two-way boss 5, and a casting boss 9.

[0029] The vertical plane is arranged perpendicular to the Yuanbao beam; the vertical side of the inverted L-shaped structure is parallel to the vertical plane. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com