Mower with independent heat dissipation air duct

A heat dissipation air duct and lawn mower technology, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of unreasonable location of motor heat dissipation vents, easy entry of water mist, easy entry of grass dust, etc. , to achieve the effect of reducing dust entering the motor, compact structure, and speeding up the air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

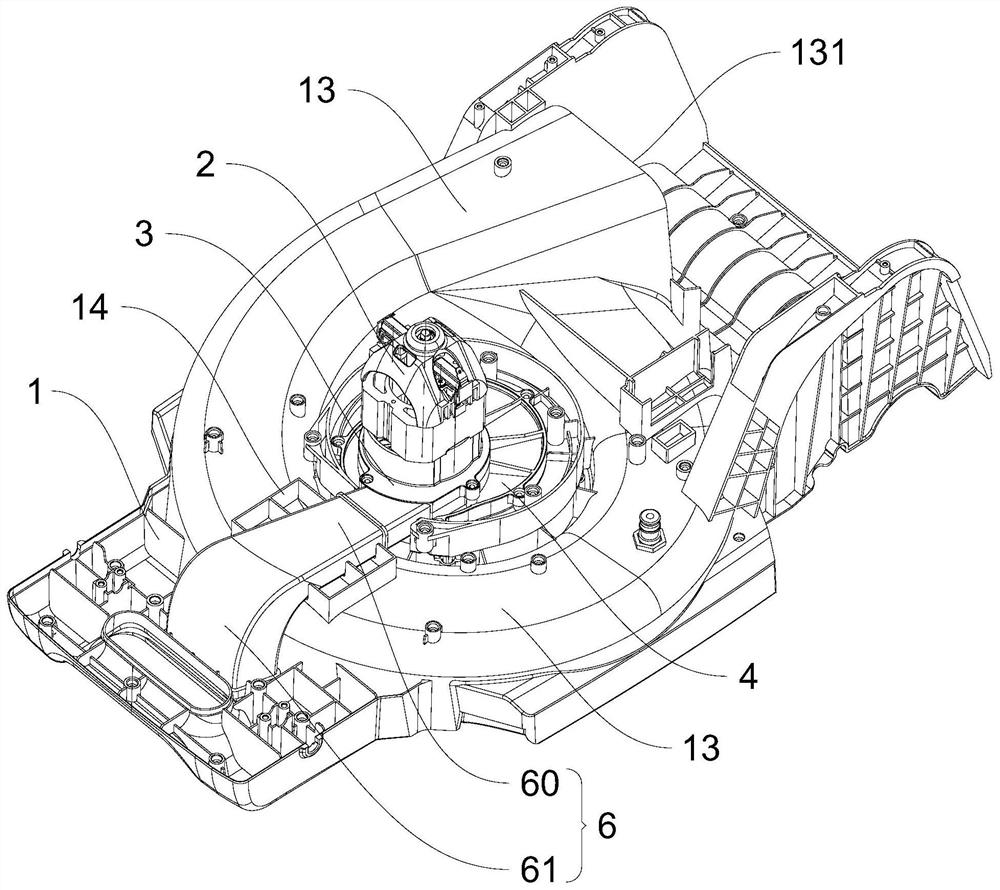

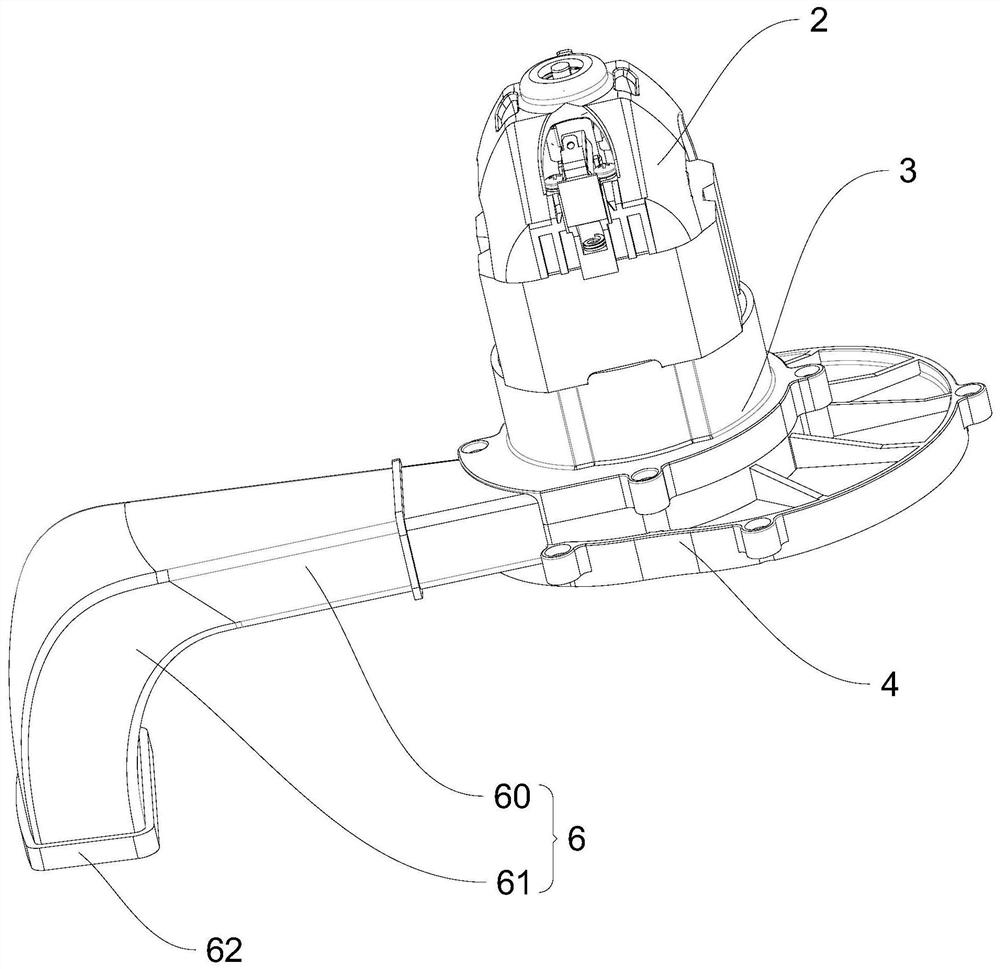

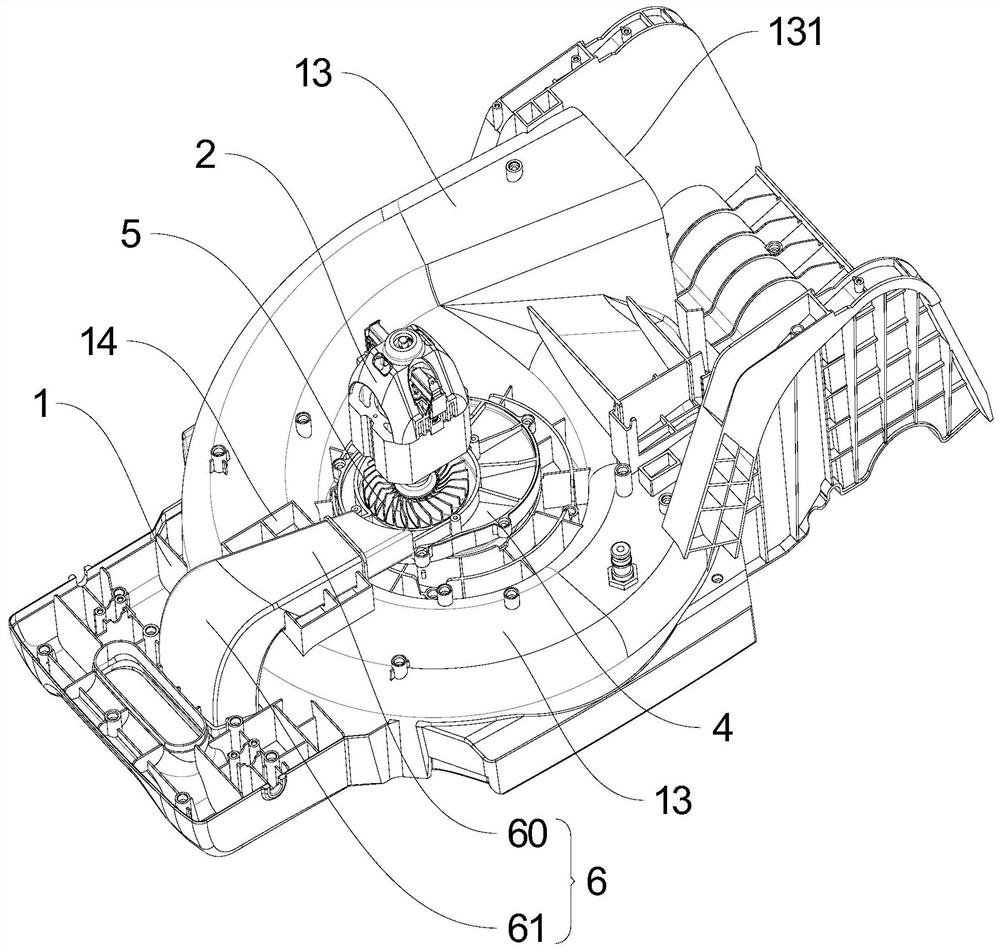

[0025] Embodiment one: if figure 1 As shown, the lawn mower with independent heat dissipation air duct provided by this embodiment includes a chassis 1, a motor 2, a motor base 3 and a motor support plate 4, and a volute 13 is arranged on the chassis 1, and the volute 13 surrounds the motor support plate 4 are arranged in a circle, the volute 13 mentioned here refers to the annular raised part on the chassis 1, that is, the volute 13 and the chassis 1 are integrally formed, because it is shaped like a snail shell, it is called a volute 13. combine figure 2 As shown, the motor 2 is installed on the motor base 3, the motor base 3 is connected to the motor support plate 4, the motor support plate 4 is connected to the chassis 1, and the motor 2 is fixedly supported on the chassis 1 by the motor base 3 and the motor support plate 4. combine image 3 and Figure 4 As shown, the middle part of the output shaft of the motor 2 is provided with a cooling vane 5, the motor base 3 a...

Embodiment 2

[0032] Embodiment two: if Figure 6 and Figure 7 As shown, the difference between this embodiment and the above-mentioned embodiments is that the lawn mower with independent heat dissipation air duct provided by this embodiment is also provided with a first air guide vane 11 in the air outlet 10, and the first air guide vane 11 One end of one end is flush with the edge of the air outlet 10 or stretches out the air outlet 10, and the surface of the chassis 1 between the grass collecting passage 130 and the air outlet 10 is provided with an air supply slot 15, and the first air guide vane 11 is connected with the air supply. The groove 15 is used to make part of the cooling air flow into the grass collecting channel 130 .

[0033] Based on the above-mentioned distinguishing technical features, in this embodiment, by setting up the air supply groove 15 on the chassis 1 between the air outlet 10 and the grass collection channel 130, and cooperating with the first air guide vane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com