Oxygen-controlled roasting device and method containing activated carbon carrier and catalyst

A roasting device and catalyst technology, applied in the direction of catalyst carrier, chemical instrument and method, catalyst activation/preparation, etc., can solve the problems of roasting equipment failure, local combustion and continuous production, etc., to prevent or reduce oxygen from entering the rotary kiln, Achieve continuous industrial production and avoid fire and combustion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

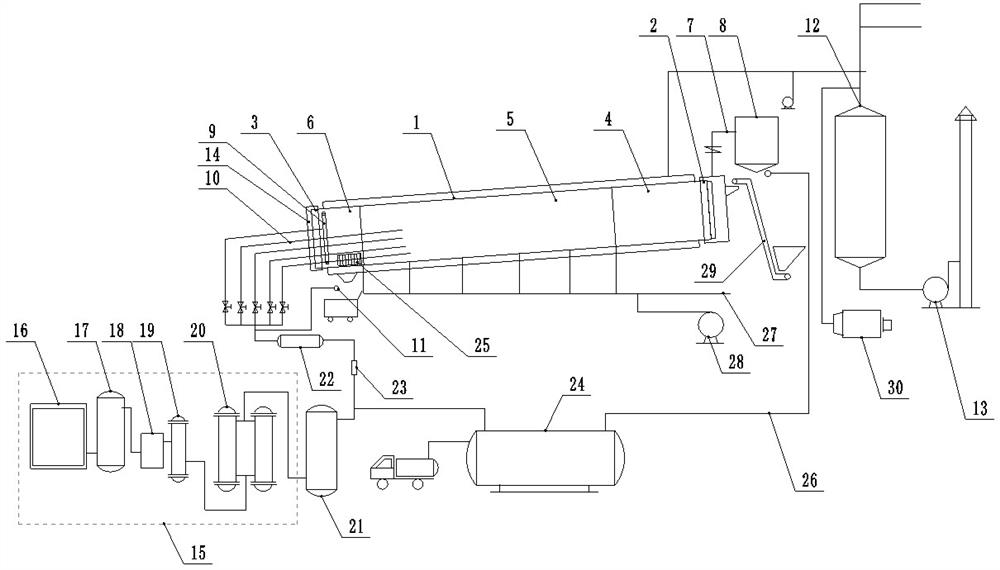

[0026] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with reference to the accompanying drawings and in conjunction with embodiments. It should be noted that, in the case of no conflict, the features in the implementation manners and examples in the present application can be combined with each other.

[0027] The oxygen-controlled roasting device containing activated carbon carrier and catalyst provided in a typical embodiment of the present invention includes a rotary kiln 1, the two ends of the rotary kiln 1 are respectively provided with a feed end 2 and a discharge end 3, and the rotary kiln 1 From the feed end 2 to the discharge end 3, it is sequentially divided into a preheating section 4, a roasting section 5 and a cooling section 6. The feed end 2 of the rotary kiln 1 is connected to the inlet end of the dust collector 8 through the exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com