Device and method for grinding and / or polishing planar surfaces of workpieces

A flat surface, polishing tool technology, used in grinding and/or polishing flat surfaces,: the field of grinding and/or polishing tools can solve problems such as the inability to apply flat optics polishing, and achieve the effect of prohibiting undesired pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

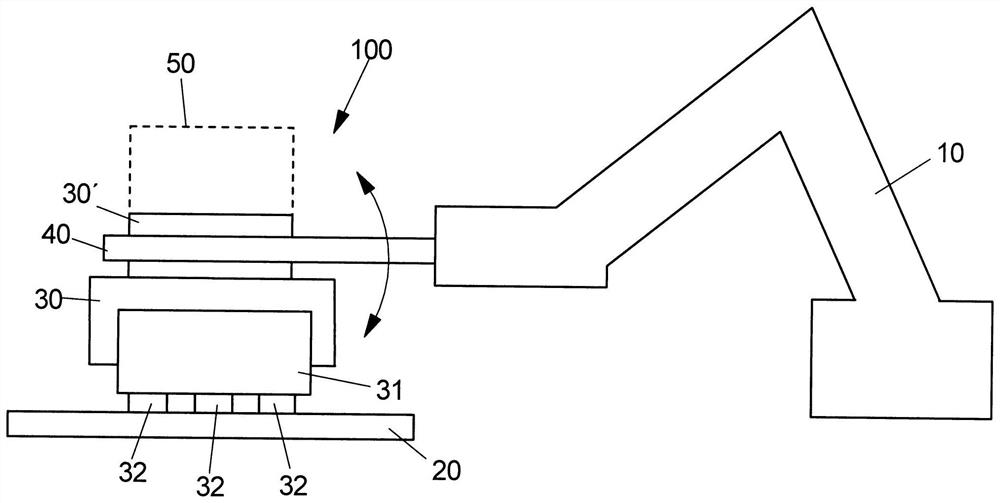

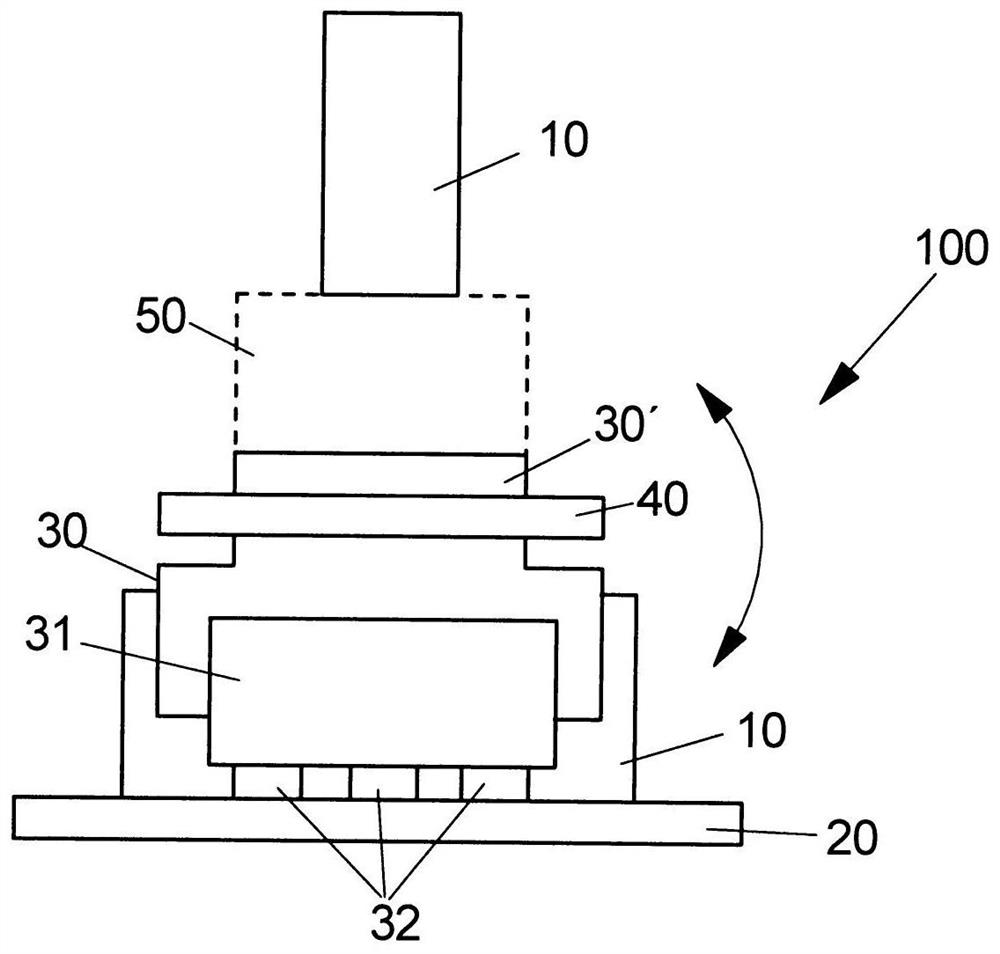

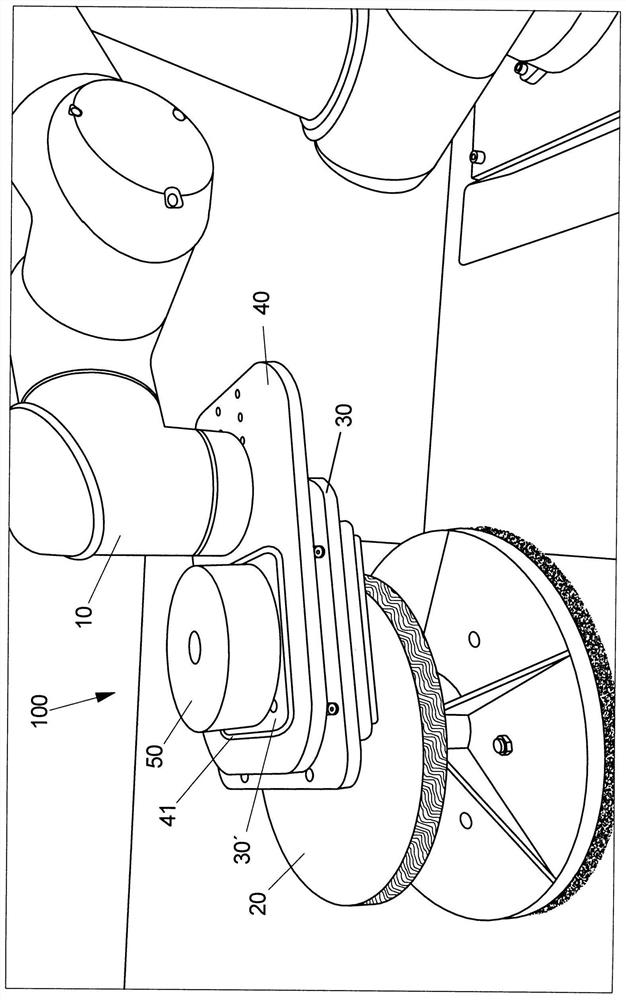

[0080] Figure 1 schematically in side view ( Figure 1A ) and front view ( Figure 1B) shows an embodiment of a device 100 according to the invention comprising a frame 40 and a workpiece holder 30 and a grinding and / or polishing tool 20 with a tool carrier or support 31 A workpiece 32 or a plurality of workpieces 32 to be ground or polished. The workpiece holder 30 together with the frame 40 forms a floating bearing, i.e. the workpiece holder 30 has an upper part 30' which is arranged in the frame 40. The upper part 30' of the workpiece holder is not fixedly connected to the frame 40, but protrudes into the opening of the frame 40 and is movably arranged in the opening of the frame 40. The frame 40 is connected to means 10 for moving the frame 40 . The movement of the frame 40 is transmitted to the workpiece holder 30, the support body 31 and the workpiece 32 connected thereto via the upper part 30' of the workpiece holder 30. In the embodiment shown here, the means ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com