Cast iron jacking pipe polishing and dust removing device

A technology of dust removal device and pipe jacking, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., which can solve the problems of inability to remove dust and inconvenient clamping of cast iron pipe jacking, so as to improve practicability and simplify work program effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

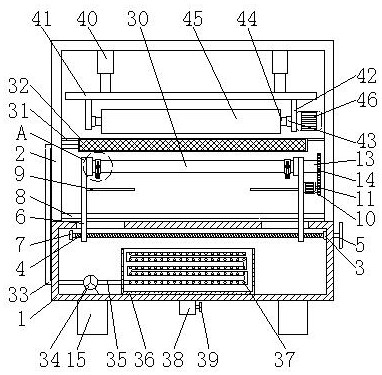

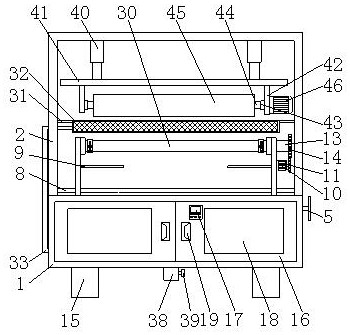

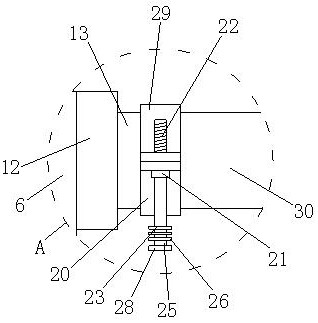

[0029] Embodiment: First adjust the distance between the splints 6 according to the length of the workpiece. By rotating the turntable 5, the turntable 5 drives the first threaded rod 4 to rotate. It is necessary to adjust the spacing of the splint 6, put the workpiece into the cavity between the fixed arc plate 20 and the moving arc plate 29, and by turning the rotating plate 28, the rotating plate 28 drives the second rotating rod 25 to rotate, and the second turning The rod 25 drives the second belt pulley 26 to rotate, the second belt pulley 26 drives the first belt pulley 23 to rotate through the belt 27, the first belt pulley 23 drives the second threaded rod 22 to rotate, and the second threaded rod 22 drives the circular arc plate 29 Move toward the fixed arc plate 20 to realize the clamping of the workpiece. By controlling the first motor 10 to work, the first motor 10 drives the first gear 11 to rotate, the first gear 11 drives the second gear 14 to rotate, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com