Full-automatic high-speed dried tofu shredding machine

A fully automatic shredding machine technology, applied in metal processing, etc., can solve problems such as unsightly appearance, broken dried bean shreds, and inability to adjust the size of dried bean shreds, so as to achieve the effect of ensuring hygiene, safety and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Now assemble accompanying drawing, further elaboration to the present invention.

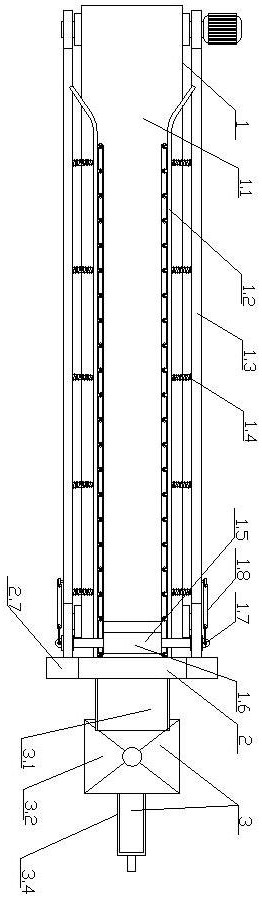

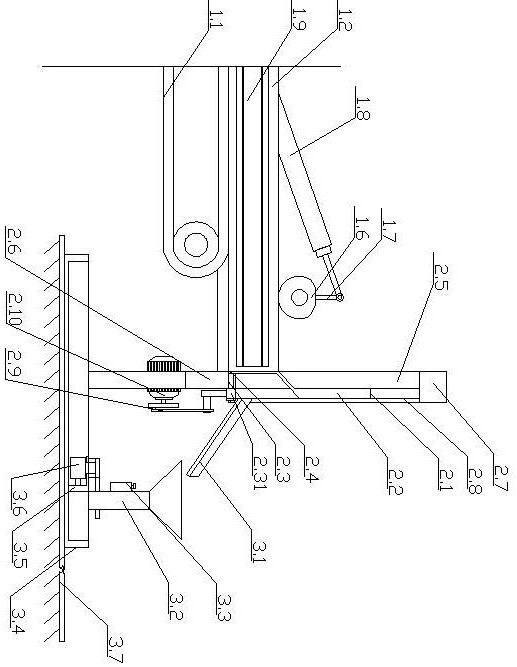

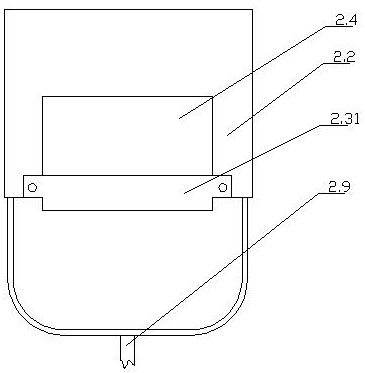

[0017] like Figure 1-4 As shown, a fully automated high-speed dried tofu shredding machine includes an automatic conveying mechanism 1, a dried tofu shredding mechanism 2 and a dried tofu shreds finishing mechanism 3, wherein the automatic conveying mechanism 1 and the dried tofu shreds sorting mechanism 3 are located in the On both sides of the dry shredding mechanism 2, the automatic conveying mechanism 1 includes a conveyor belt 1.1, a splint 1.2, a fixed frame 1.3, an elastic clamping assembly 1.4 and an auxiliary conveying assembly 1.5, wherein a fixed frame 1.3 is arranged on both sides of the conveyor belt 1.1 and fixed The frame 1.3 is fixed on the ground by bolts, two splints 1.2 are arranged on the front and rear two fixed frames 1.3 and the two splints 1.2 are located on both sides of the conveyor belt 1.1 (a plurality of beans are arranged on the inside of each fixed frame 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com